Quick interception liquid pneumatic jet nozzle

A pneumatic nozzle and liquid technology, which is applied in the field of rapid interception of liquid pneumatic nozzles, can solve the problems of insufficient production capacity, easy wear on the surface, poor sealing effect, etc., so as to improve the sealing effect and reduce walking. Path, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but not as improper limitations to the present invention.

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

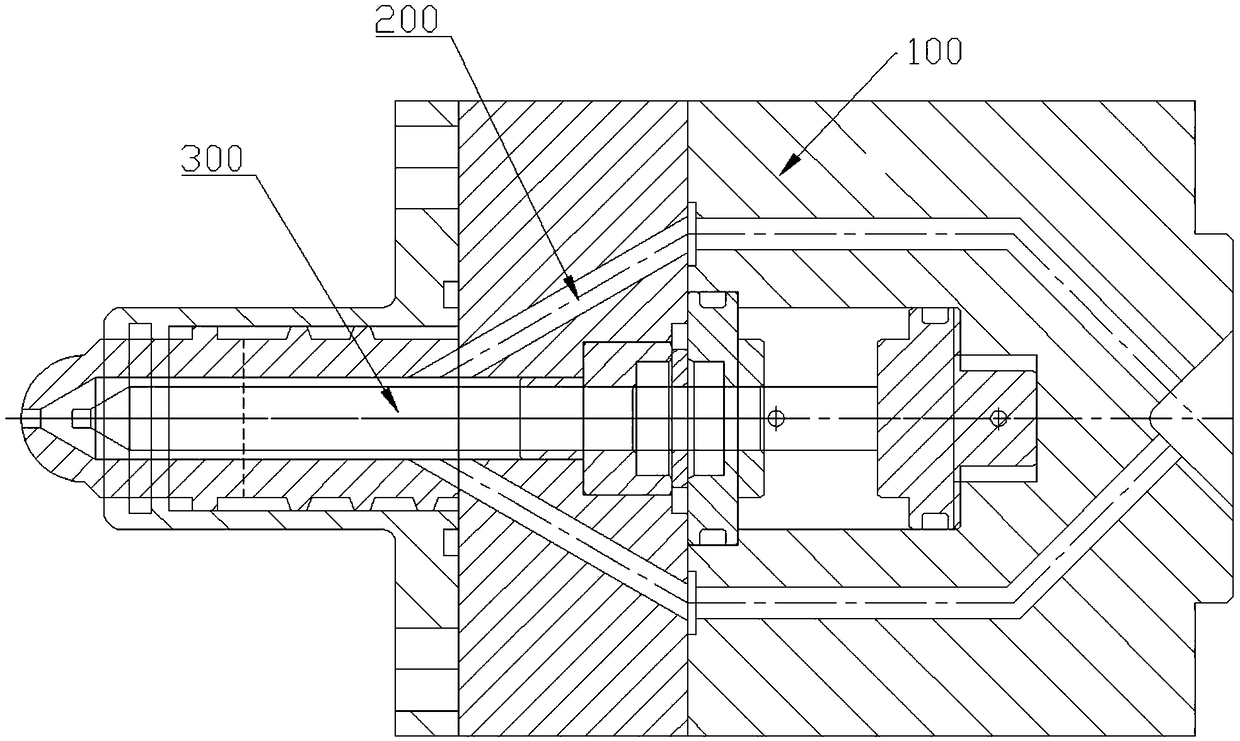

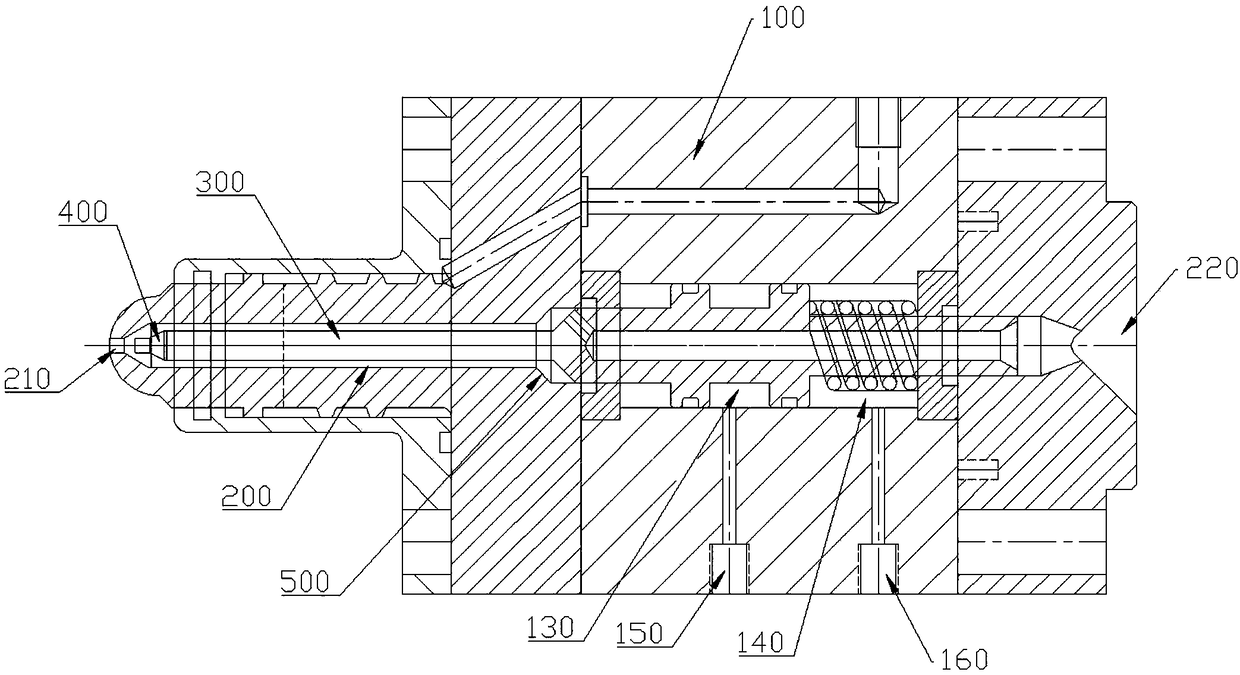

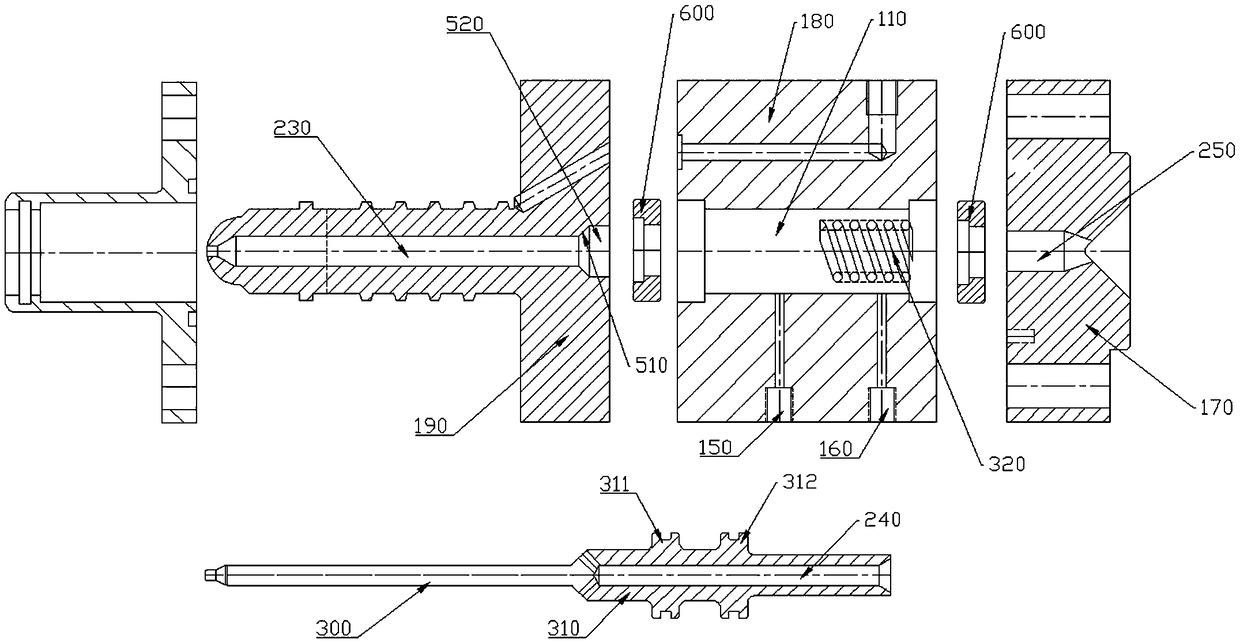

[0032] The fast shut-off liquid pneumatic nozzle includes a nozzle body, the nozzle body is provided with a rubber channel and a valve needle, the front end of the rubber channel is provided with a rubber outlet, and the rear end is provided with a rubber inlet; The rubber sealing part, the first sealing part seals the rubber material outlet when the valve needle moves along the rubber material channel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com