Vacuum assisted method and equipment for preventing outflow of rubber by screw extrusion continuous dehydration drying

A vacuum-assisted, screw-extruded technology, which is applied in the field of post-processing of synthetic rubber or wet-mixed rubber, can solve the problems of undisclosed anti-emission shaftless screw device, easy-emission of extruder exhaust port, undisclosed, etc. Deep variable pitch screw and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

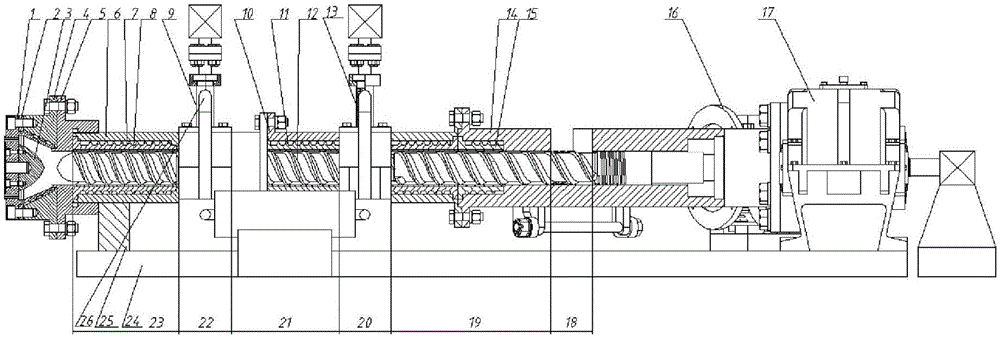

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

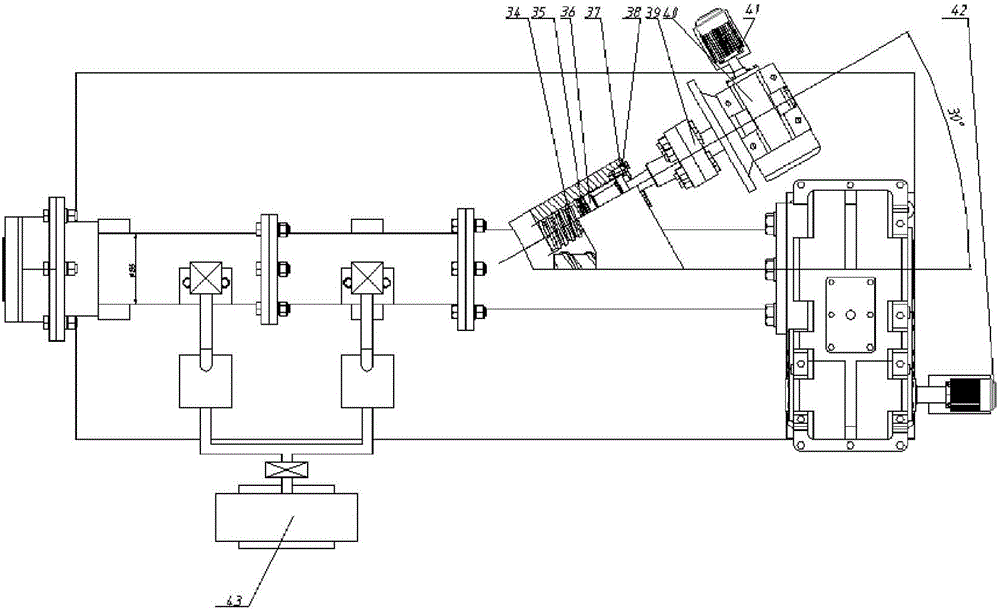

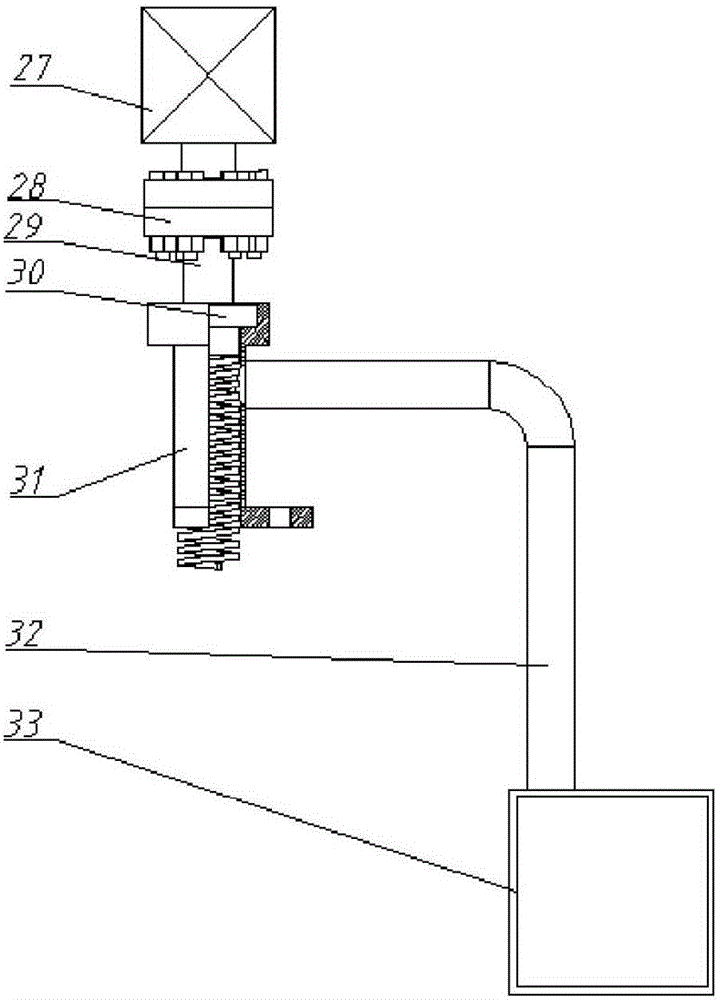

[0028] Such as figure 1 , figure 2 , image 3 As shown in the figure, a rubber vacuum-assisted screw extrusion continuous dehydration and drying anti-emission equipment, its main structure includes a nose die 1, a nose jacket 2, a shunt shuttle 3, a nesting body 4, a connecting body 5, and a machine barrel Section 6, Cooling water jacket Section 7, Bushing 8, Vacuum pumping device 1 9, Barrel 2 section 10, Cooling water jacket 2 section 11, Screw 12, Vacuum pumping device 2 13, Machine barrel 3 section 14, Cooling water jacket Three sections 15, feeding device 16, reduction box 17, base 24, bracket 25, the machine head is composed of four parts: nose die 1, machine head jacket 2, shunt shuttle 3, nesting body 4, machine barrel is composed of The first section of the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com