Using method of linkage type discharging valve

A blanking valve and linkage technology, applied in the field of medium conveying control, can solve the problems of increasing production and installation costs, increasing material accumulation, poor stability, etc., to achieve the effect of enhancing sealing performance, avoiding material accumulation and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

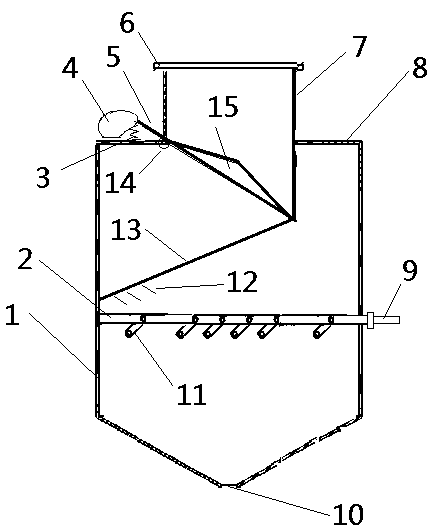

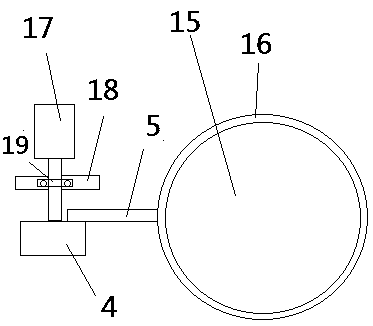

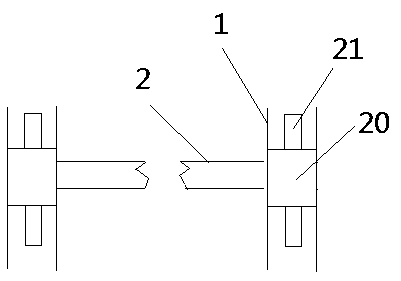

[0043] As shown in the figure: a method of using a linkage type blanking valve. The blanking valve includes a cylinder, a partition, a spring, a wheel, a pole, a flange, a straight cylinder, a cylinder shoulder, a cylinder, a discharge port, Blades, combs, telescopic rods, fulcrums, conical discs, damping rings, servo motors, brackets, hoops, rotating rings, protrusions; their use methods include working methods and adjustment methods;

[0044] As shown in the figure: a cylinder shoulder is set above the cylinder, the middle of the cylinder shoulder extends upwards to form a straight cylinder, a flange is arranged above the straight cylinder, a part of the straight cylinder extends downward from the horizontal line of the cylinder shoulder to form an inclined opening and closing opening, and the conical disk is closed Or to open the opening and closing opening, a pole is arranged on the upper left of the conical disc, and the fulcrum is set at the junction of the cylinder shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com