Bus redundancy control system in thermal power plant

A thermal power plant, bus redundancy technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as difficult to distinguish easily, long drag line distance, abnormal signal, etc., and achieve the effect of simple resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

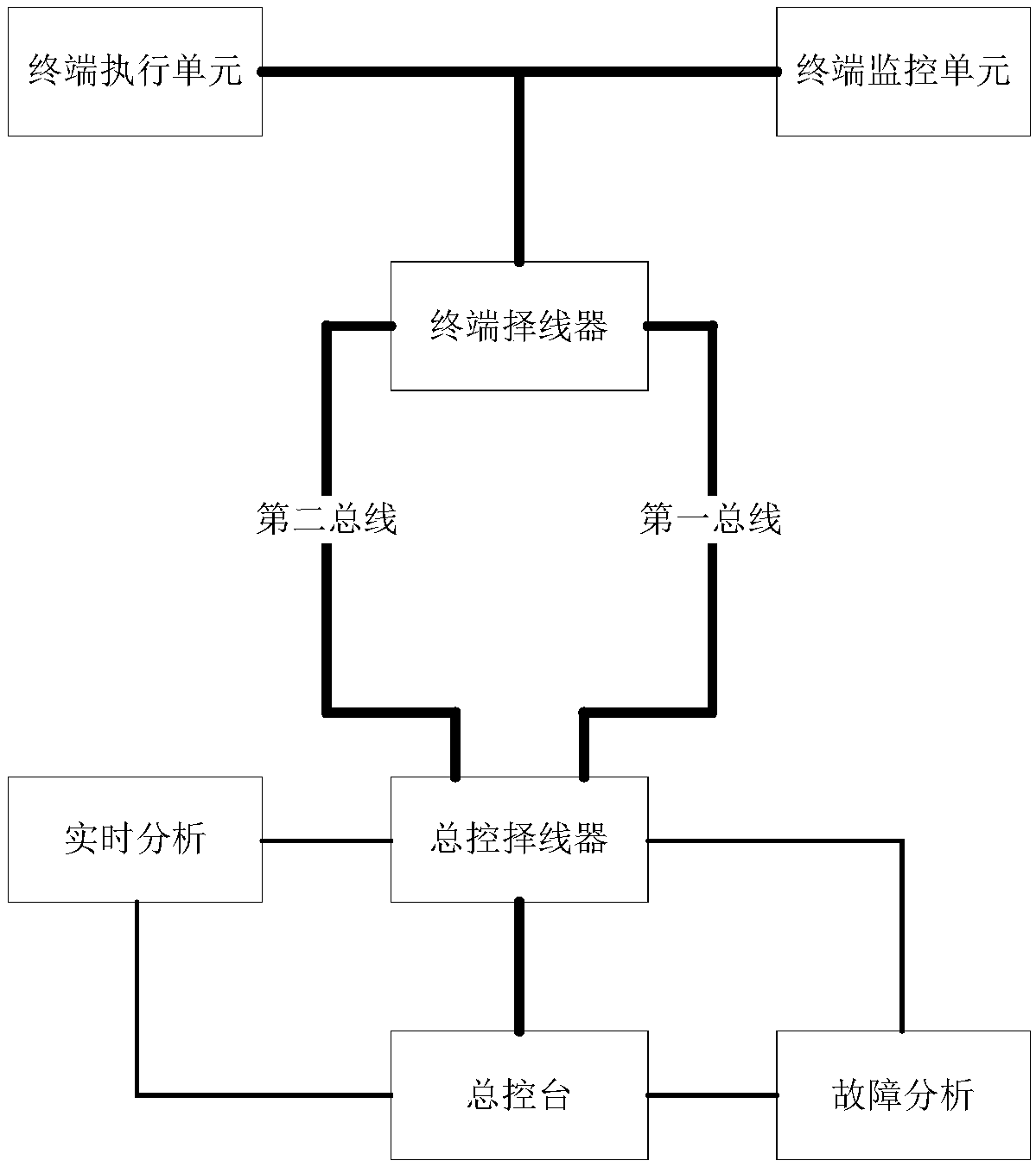

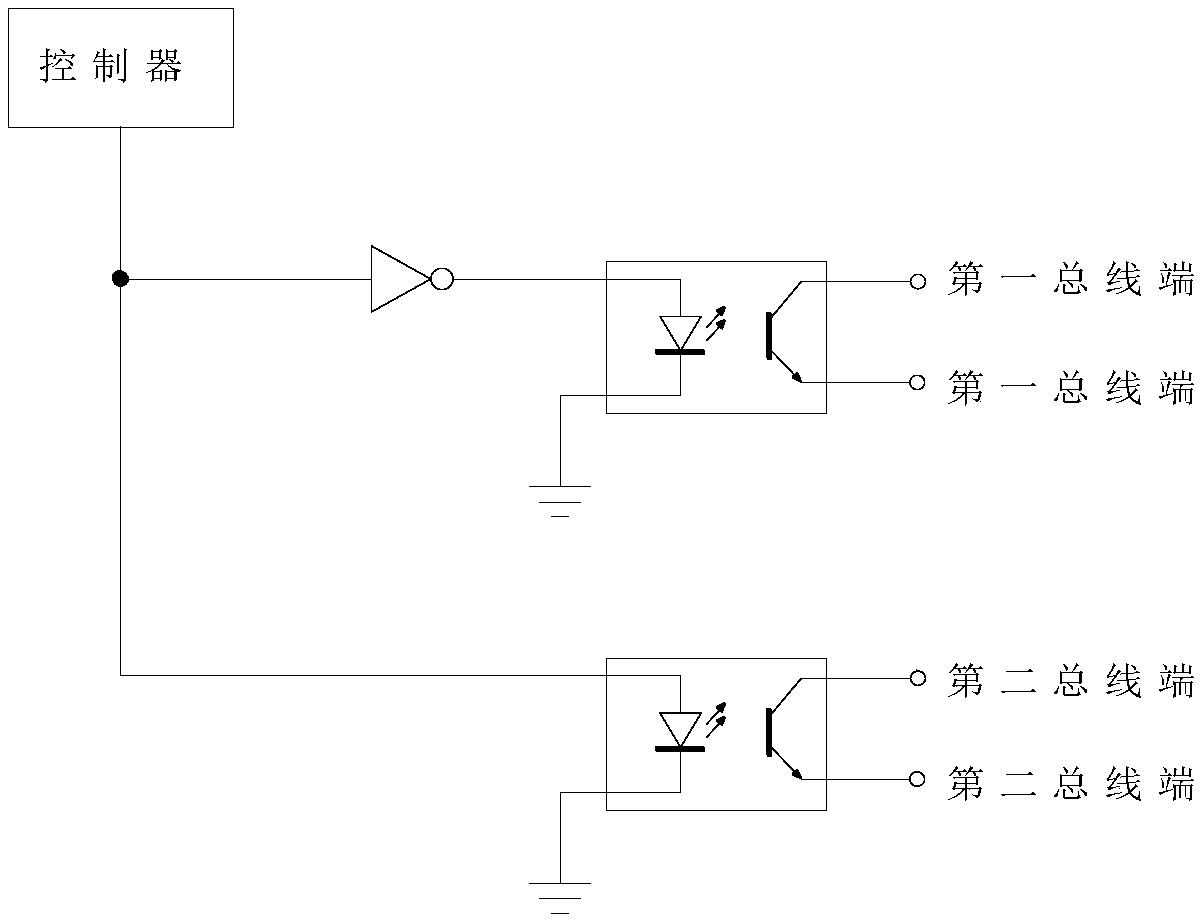

[0019] like figure 1 A thermal power plant bus redundancy control system shown includes a terminal wire selector and a master control wire selector; the terminal wire selector and the master control wire selector are sequentially connected to the bus between the terminal and the master console Above, between the terminal line selector and the master control line selector, the bus is divided into two lines, the first bus and the second bus. The first bus and the second bus are both PROFIBUS buses. The terminal has a terminal execution unit and a terminal The monitoring unit is connected to the bus; the terminal wire selector and the master control wire selector are controlled so that only one bus is connected to the first bus and the second bus at the same time; the master control wire selector is connected with a real-time analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com