A Dynamic Light Source System for Laser Speckle Dissipation

A light source system and speckle dissipation technology, applied in the field of laser speckle dissipation light source systems, can solve problems such as difficulty in finding intermediate specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

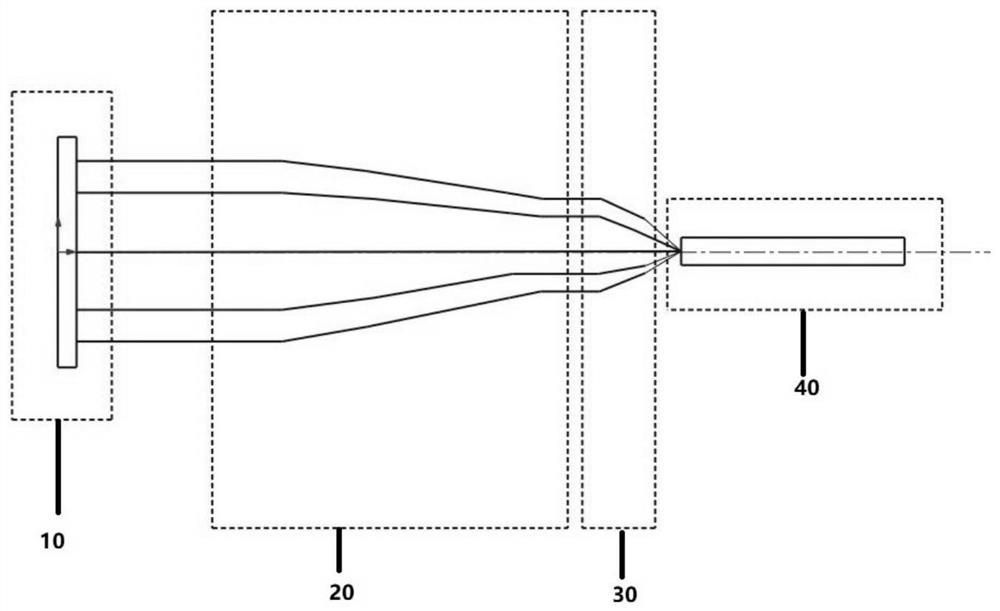

[0054] Such as figure 1 As shown, a dynamic light source system for laser speckle dissipation includes a light source assembly 10, a beam reduction system 20 for combining the laser beams emitted by the light source assembly 10, a focusing assembly 30, and a uniform light device 40; The focusing assembly 30 is disposed between the beam shrinking system 20 and the light homogenizing device 40 , and the focusing assembly 30 is used to focus the laser beam passing through the beam shrinking system 20 and enter the light uniforming device 40 for light homogenization.

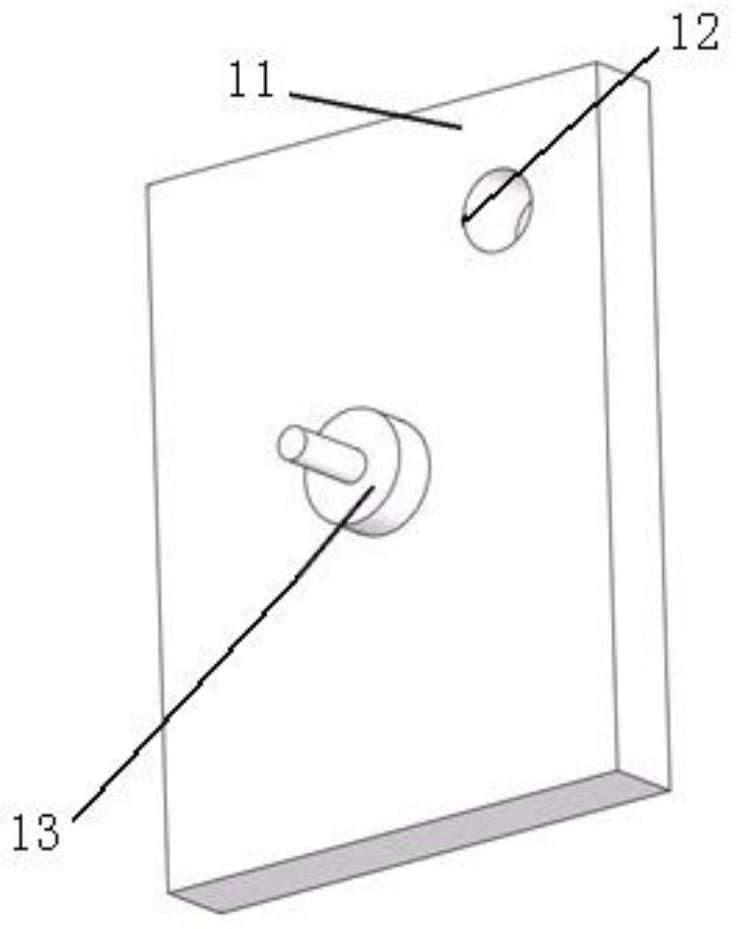

[0055] The light source assembly 10 includes a laser fixing substrate 11, a laser 14, a vibrating assembly 13 and an alignment assembly 15. The laser fixing substrate 11 is provided with a plurality of through laser fixing holes 12, and each laser fixing hole 12 is fixed with a Lasers 14 , each laser 14 is connected with a collimating component 15 , and the vibrating component 13 is connected on the laser fixing sub...

Embodiment 2

[0063] Such as figure 1 As shown, this embodiment provides an array arrangement of lasers 14 relative to Embodiment 1, so that the structure of the light source assembly 10 is more compact, and the light source assembly 10 is illustrated with reference to image 3 , the laser fixing substrate 11 is provided with several through laser fixing holes 12, each laser fixing hole 12 is fixed with a laser 14, and each laser 14 is connected with a collimation assembly 15, and the vibration assembly 13 is connected to the laser fixing on the substrate 11. The arrangement of the lasers 14 on the laser fixed substrate 11 and the reference direction of the fast axis Image 6 , wherein the wavelength of the laser 14 used is the same, and the requirements for the vibrating component 13 are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0065] In this embodiment, the vibration component 13 is a plurality of vibration micro components 131, the number of the vibration micro components 131 is equal to the number of lasers 14, each vibration micro component 131 is connected to the corresponding laser 14, and the laser 14 The direction of the slow axis of the laser is perpendicular to the direction of the fast axis of the laser 14 . The vibration micro-component 131 is designed separately for each laser 14, so that the vibration mode of each laser 14 is independent, and the specific schematic diagram refers to Figure 7 , the diagram shows the array arrangement of the lasers 14, and the fast axis direction of the lasers 14 refers to Image 6 , the vibration amplitude of the vibration microcomponent 131 is independently designed with respect to the central wavelength of the laser 14 it controls.

[0066] The central wavelengths of the lasers 14 used in this embodiment can be the same or different, and the light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com