Solar cell, manufacturing method thereof, and solar cell module

A solar cell and electrode technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of solar cell performance degradation and complex solar cell manufacturing methods, and achieve the effect of improving open circuit voltage and fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

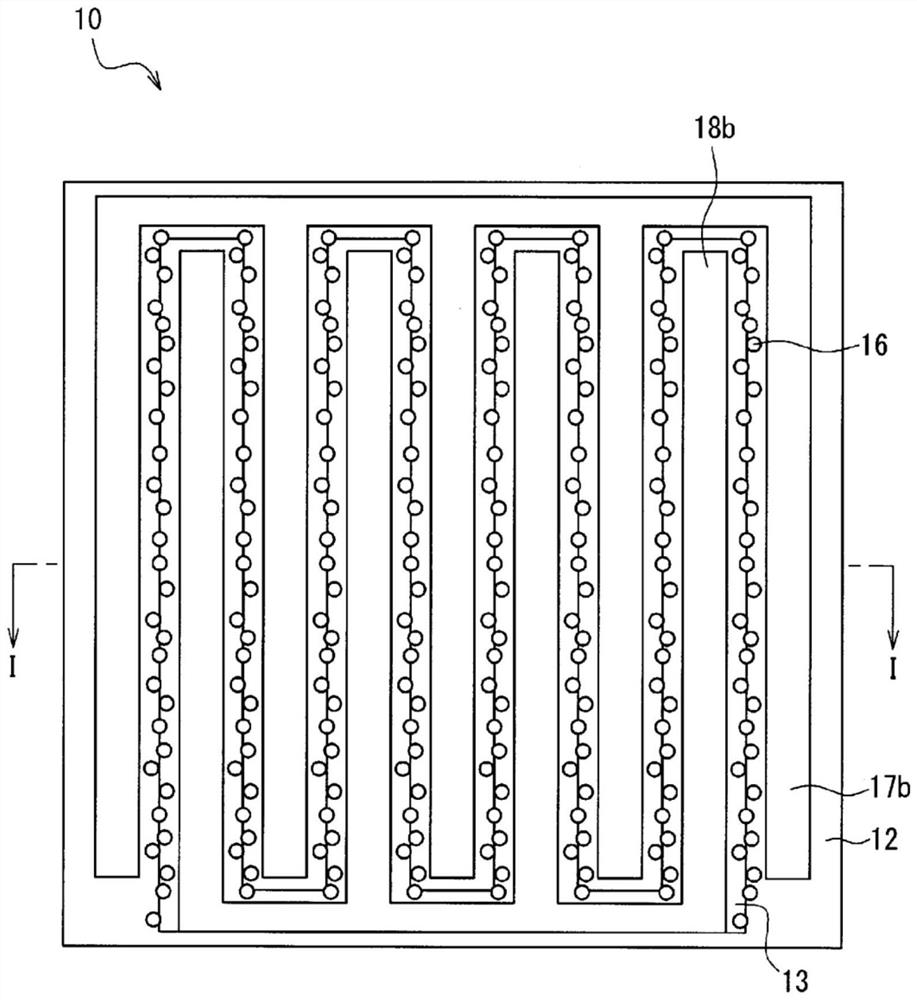

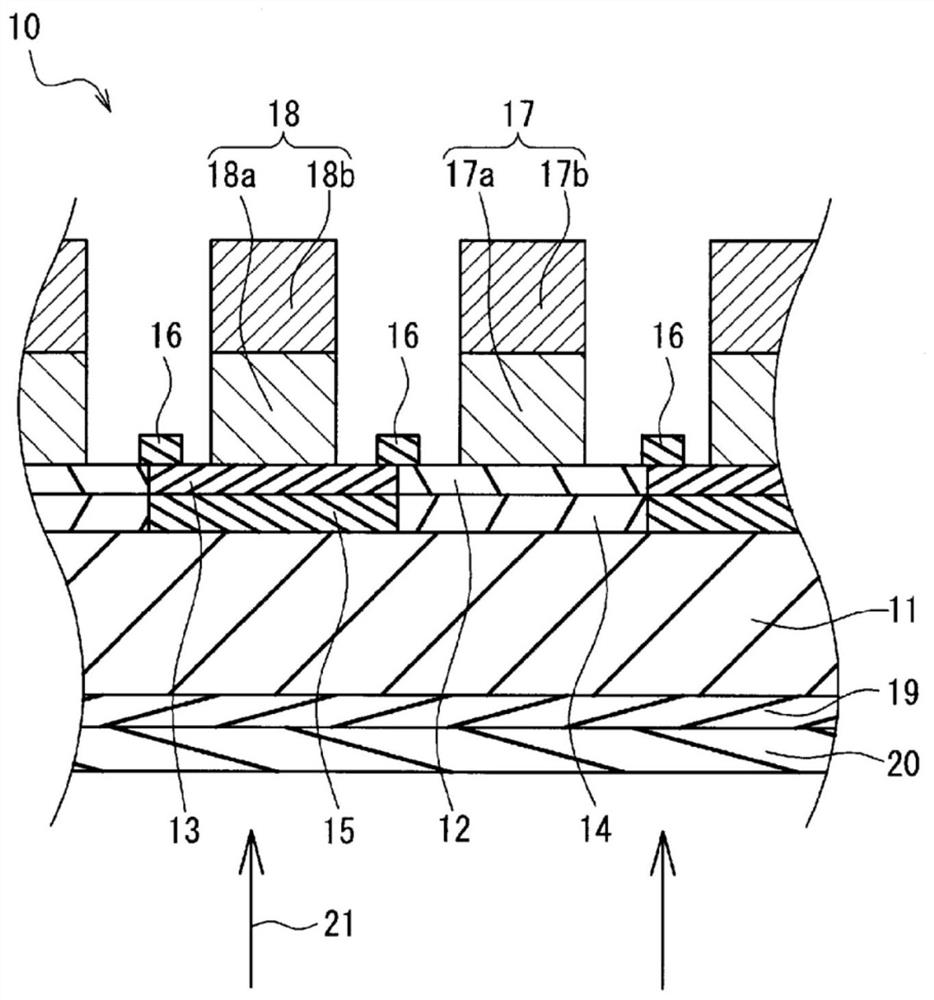

[0108] First, as described below, except that no antireflection layer is formed, by Figure 5 The process shown makes figure 2 The back electrode type solar cell shown.

[0109] First, prepare an n-type single-crystal silicon substrate 11 with an incident plane orientation of (100), wash the substrate in acetone, and then immerse it in a 2% by mass hydrofluoric acid aqueous solution for 5 minutes to remove the silicon oxide film on the surface. Rinse twice with ultrapure water. The substrate was immersed in a mixed aqueous solution of 5% by mass KOH / 15% by mass of isopropanol kept at 75° C. for 15 minutes to etch the surface of the substrate to form a texture on the surface of the substrate. Thereafter, it was immersed in a 2% by mass hydrofluoric acid aqueous solution for 5 minutes, washed twice with ultrapure water, and dried at normal temperature. At this stage, the surface of the n-type single crystal silicon substrate was observed using an atomic force micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com