Novel firm steel bottle stable anti-explosion piece

An explosion-proof disc and firm type technology, which is applied in the field of firm-type cylinder-stabilized explosion-proof discs, which can solve the problems of easy explosion and single safety protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

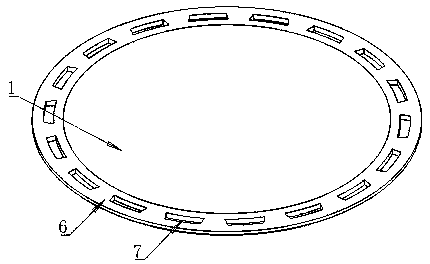

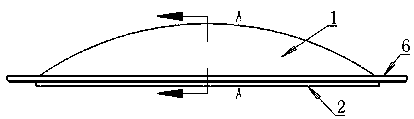

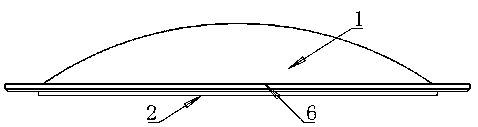

[0019] Such as Figure 1 to Figure 7 As shown, a new type of solid steel cylinder stable explosion-proof disc, which is used in conjunction with the main structure of the steel cylinder, is usually installed at the upper end of the steel cylinder structure. The safety pressure value at the output port is smaller. During use, if the pressure in the steel cylinder is greater than the pressure of the explosion-proof disk, the position of the explosion-proof disk can be pressed open, so that the pressure in the steel cylinder can be discharged to achieve the purpose of overall safety and explosion protection. , the structure of this explosion-proof plate is provided with two safety explosion-proof grooves inside, and the two explosion-proof grooves are set to different sizes, so that it can prevent the overall explosion-proof performance from being affected by the failure of one safety explosion-proof groove during use. , so as to improve the overall explosion-proof safety. The ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com