A self-conforming eddy current detection device and method for corner cracks at the bottom of turnout rails

A technology of eddy current testing and turnout rails, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of surface corrosion, cracking, wear, fatigue cracks of turnouts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

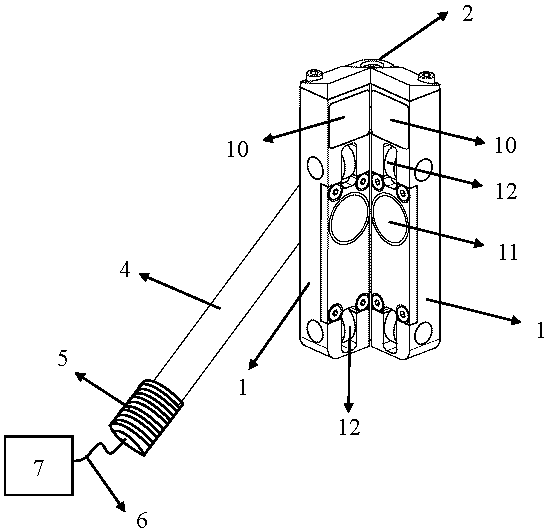

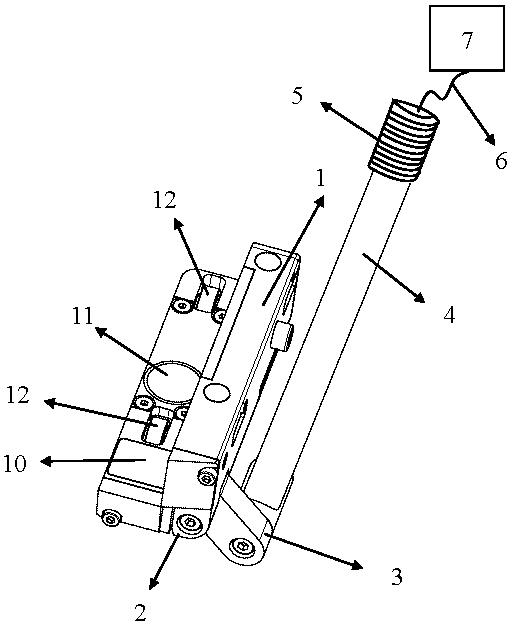

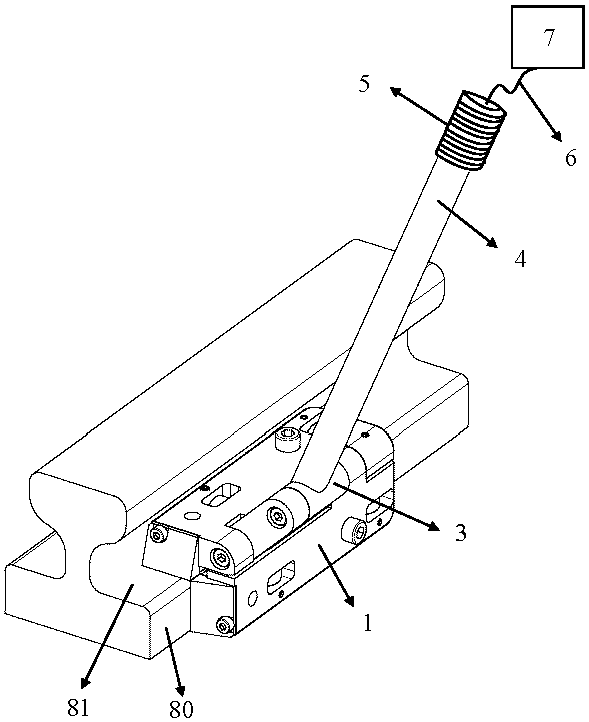

[0023] Examples such as figure 1 , 2 , As shown in 3 and 4, a self-adaptive eddy current detection device for corner cracks at the bottom of a turnout rail includes a pair of orthogonal array eddy current probe fixing plates 1, variable-angle door leaf joints 2, flexible universal joints 3, and probe rods 4. Handle 5, wire 6, array eddy current detector 7, characterized in that: the pair of orthogonal array eddy current probe fixed plates 1 are connected together through variable angle door leaf joints 2, and the orthogonal array eddy current probe fixed plate 1 The angle change between them can be self-adaptive; The orthogonal array eddy current sensor 10, the permanent magnet 12 and a pair of rolling bearings 11 are installed on the said orthogonal array eddy current probe fixed plate 1, wherein, the orthogonal array eddy current sensor 10 is fixed on the orthogonal On the left side of the fixed plate 1 of the array eddy current probe, one rolling bearing 11 of a pair of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com