Ultrasonic flaw detection method of cracks of connecting rod pin of locomotive wheel set

A flaw detection and ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problem of inability to detect the flaws of connecting rod pins, and achieve the effect of shortening the maintenance cycle of locomotives, ensuring quality and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

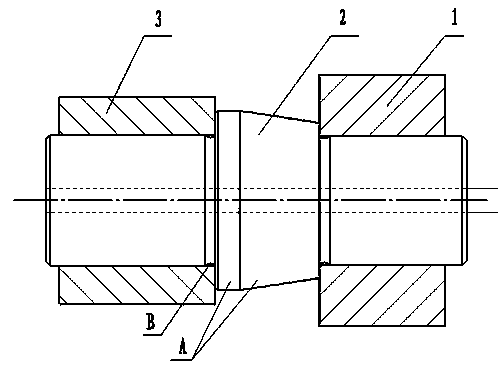

[0029] Such as figure 1 As shown, the locomotive wheel pair connecting rod pin 2 has an inner hole with a diameter of 10mm, and its end face is tapered, and one end of it extends into the No. 2 When flaw detection is required, the surface A of the connecting rod pin is used as the scanning surface for ultrasonic flaw detection, such as figure 1 , if there are cracks on the conical surface and cylindrical surface of the connecting rod pin, it is easy to be detected; if the detected crack is located on the connecting rod pin 2 in the second part 3, as figure 1 In B, the flaw detection is carried out by the ultrasonic flaw detection method described in the present invention.

[0030] The working process of the ultrasonic device is:

[0031] Electrical signal--probe--ultrasonic--parts--ultrasonic emission;

[0032] Ultrasound in the part---probe---electrical signal---ultrasonic reception.

[0033] The ultrasonic probe of the ultrasonic device of the present invention is a spec...

Embodiment 2

[0035] Carry out flaw detection on the connecting rod pin in the assembled state, and the detection method is as follows:

[0036] In the first step, the inner hole of the connecting rod pin is used as the calibration basis for the detection area and detection depth of the ultrasonic flaw detection, that is, distance measurement calibration. First of all, the special ultrasonic probe for connecting rod pins is placed on the detection surface of the test block, and the reflected wave of the incident point of the ultrasonic wave and the reflected wave of the inner hole with a diameter of 10 mm are respectively detected. 10mm inner hole reflected wave for ranging calibration.

[0037] At the same time, the reflected wave of the inner hole of the connecting rod pin is also used as the calibration basis for the comprehensive performance state of the working system during the ultrasonic flaw detection process;

[0038] In the second step, connecting rod pins with natural cracks and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com