Locomotive wheelset connecting rod pin crack ultrasonic probe

A connecting rod pin and ultrasonic technology, applied in the field of probes, can solve the problem that the crack defect of the connecting rod pin cannot be effectively detected, the in-service online detection, real-time tracking and monitoring of the connecting rod pin of the locomotive wheelset cannot be realized, and the locomotive wheelset cannot be detected. Connecting rod pin crack defects and other problems, to achieve the effect of shortening the maintenance cycle, improving reliability and safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

[0027] All features disclosed in this specification, or steps in all disclosed methods or processes, except for mutually exclusive characteristics and / or steps, can be combined in any way, unless otherwise stated, they can be used by other equivalent or similar Instead, each feature is intended to be replaced by alternative features, that is, each feature is only one embodiment of a series of equivalent or similar features unless stated otherwise.

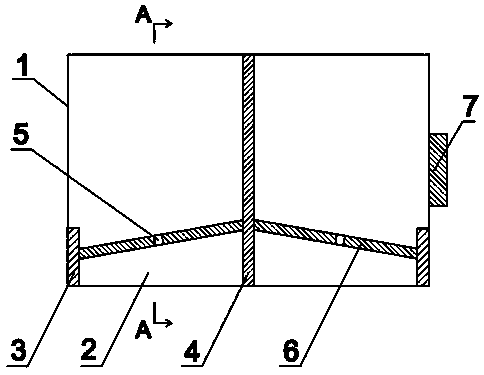

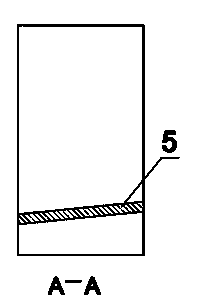

[0028] Such as figure 1 , 2 As shown, the ultrasonic probe for cracks in the connecting rod pin of the locomotive wheel set of the present invention includes two plexiglass delay blocks 2 , a sound insulation layer 4 and two dual crystal probes 6 with flaw detection wafers 5 . The sound insulation layer 4 is vertically arranged in the middle of the two plexiglass delay blocks 2, and the flaw detection chip with the transmitting e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com