Servo seepage method for fracturing gas-containing coal body with high-power impulse waves

A high-power pulsed, gaseous coal technology, used in permeability/surface area analysis, suspension and porous material analysis, instruments, etc., can solve the problems of large construction volume, complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

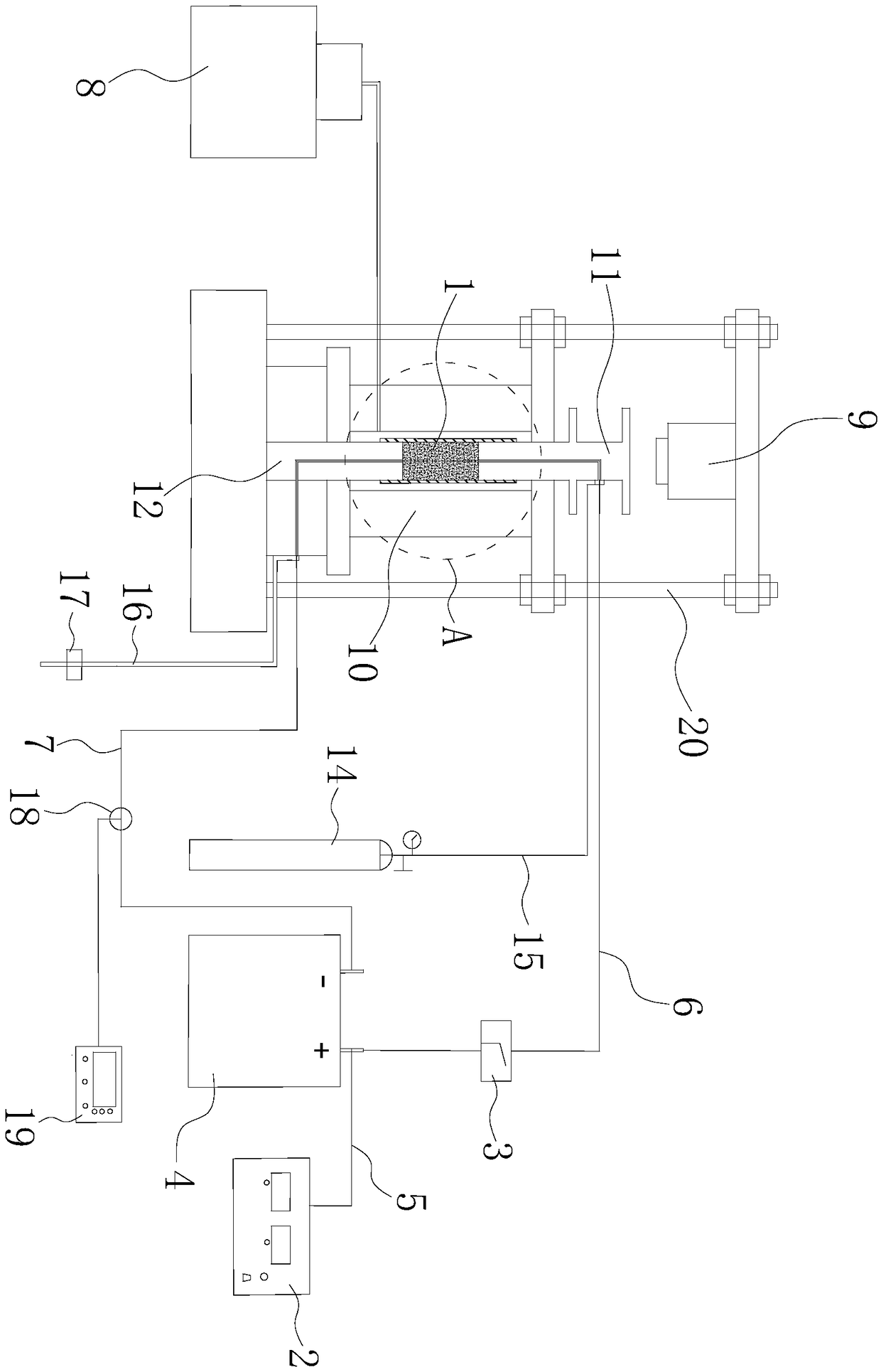

[0093] A servo seepage method for fracturing gas-containing coal bodies with high-power pulse waves, including

[0094] Step a: making coal sample 1;

[0095] Step b: installing a high-power pulse generating mechanism;

[0096] Step c: use a wire to connect the high-power pulse generating mechanism to the coal sample 1;

[0097] Step d: Operate the high-power pulse generating mechanism, so that the high-power pulse generating mechanism emits high-power pulses to the coal sample 1 with a set pulse energy to crack the coal sample 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com