Experimental method for cracking gas-containing coal mass by high-power pulse waves

A technology of high-power pulse and experimental method, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the analysis of permeability/surface area, and the use of acoustic wave emission technology for material analysis. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

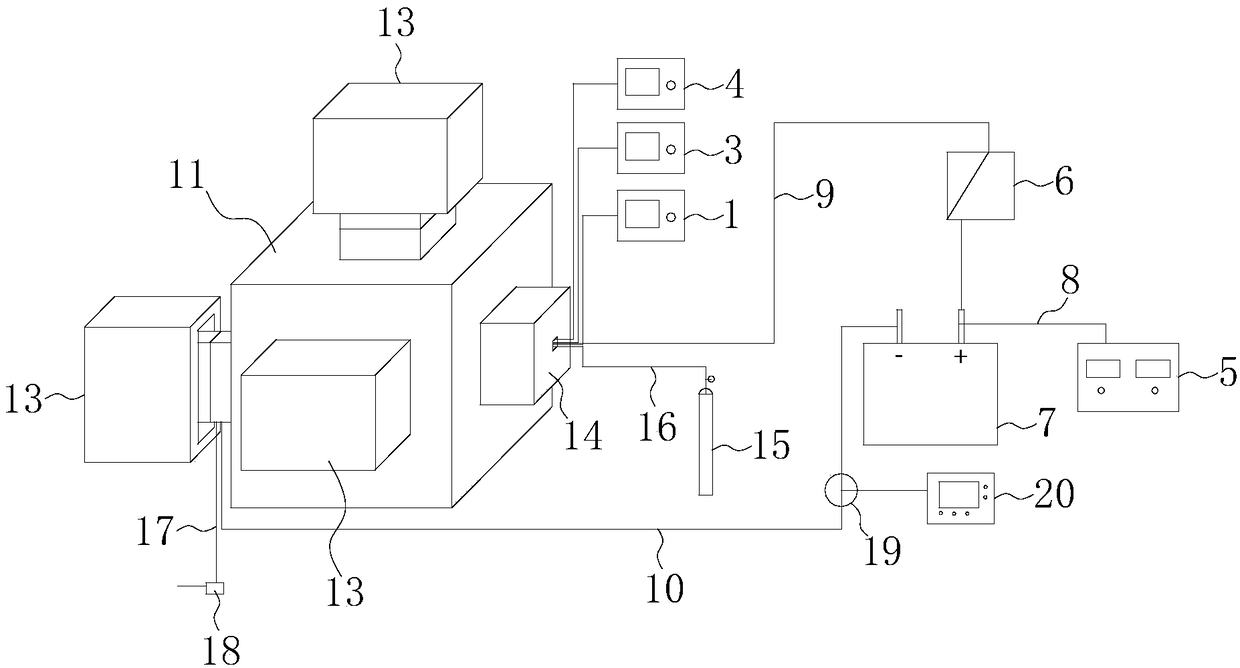

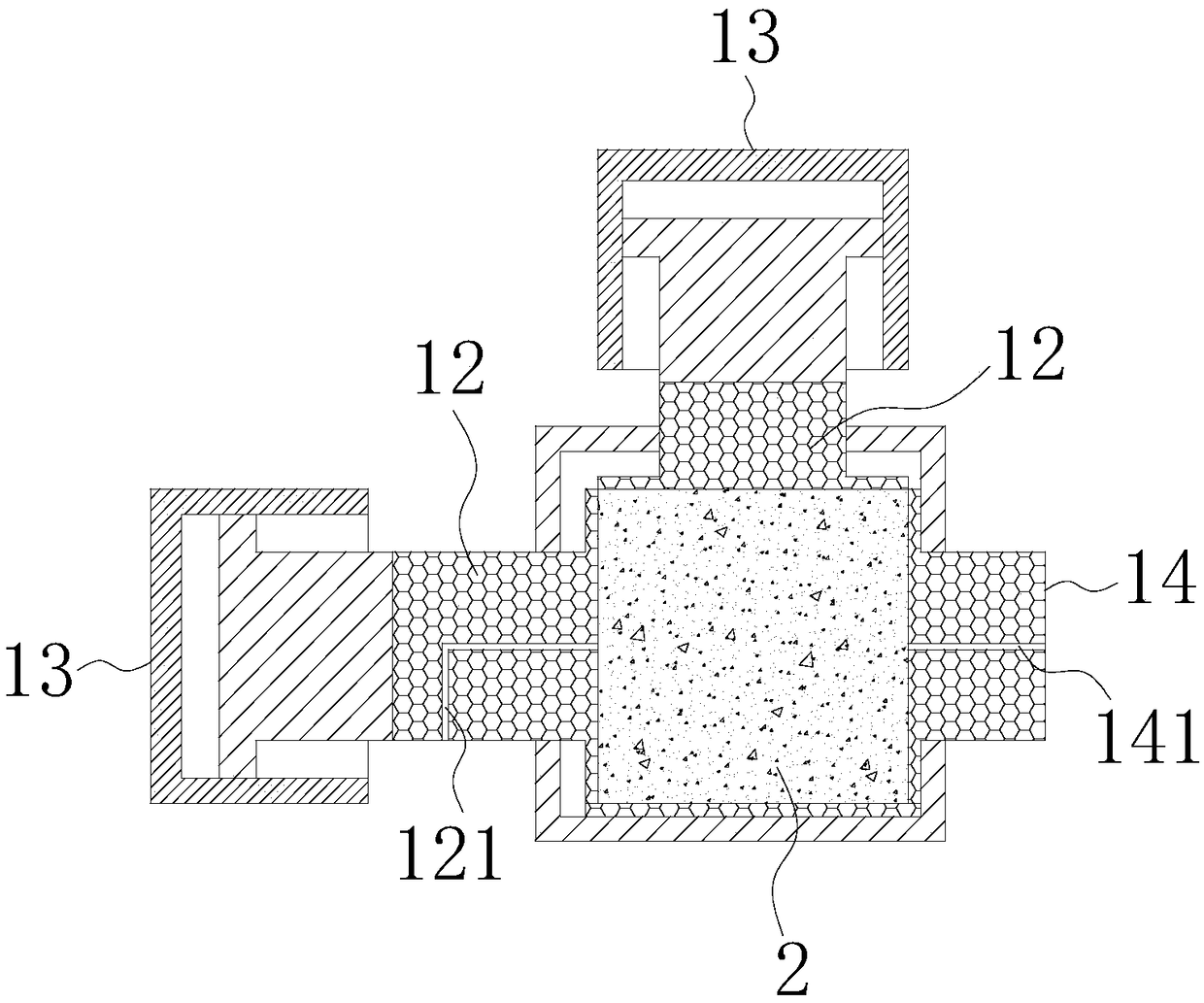

[0075] An experimental method for cracking gas-containing coal bodies with high-power pulse waves, including

[0076] Step a: making coal sample 2;

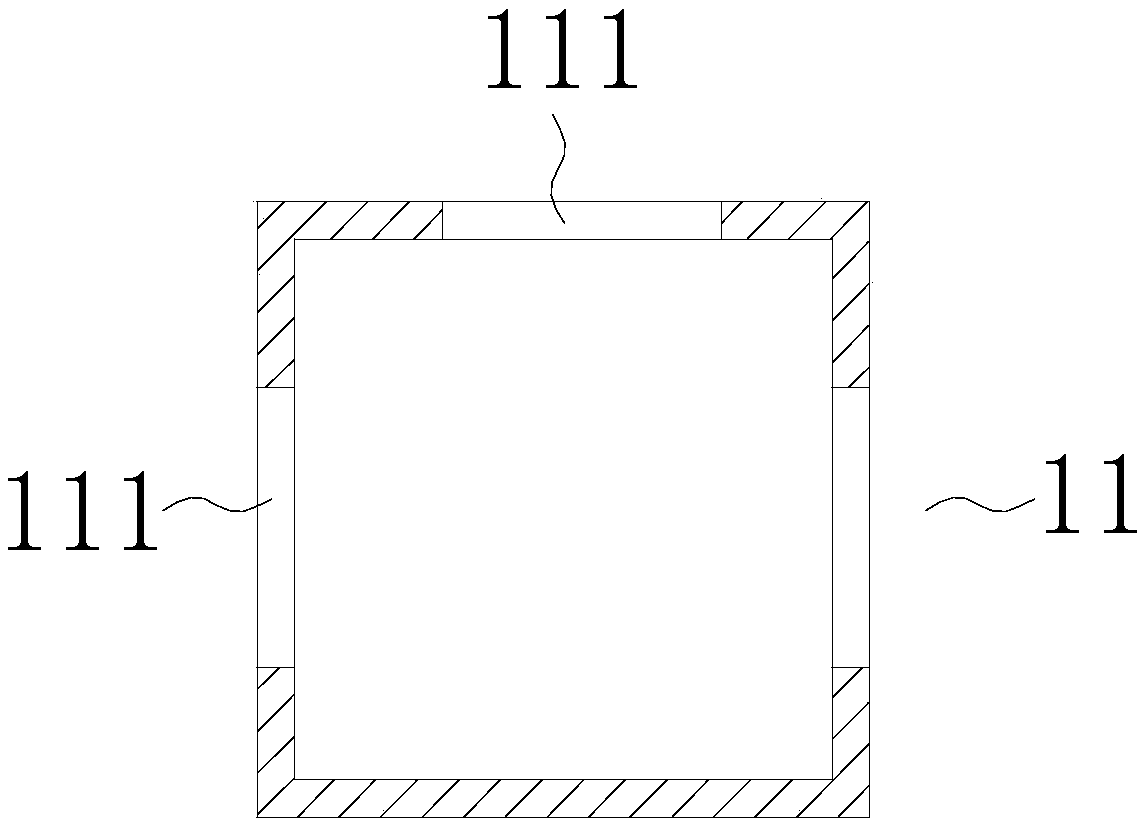

[0077] Step b: installing a high-power pulse generating mechanism, and connecting the high-power pulse generating mechanism to the coal sample 2 through wires;

[0078] Step c: installing an acoustic emission detection mechanism 1 so that the acoustic emission detection mechanism 1 cooperates with the coal sample 2;

[0079] Step d: Make the high-power pulse generating mechanism emit a high-power pulse to the coal sample 2 to crack the coal sample 2, and make the acoustic emission detection mechanism 1 detect and analyze the acoustic emission in the coal sample 2 feature.

[0080]The high-power pulse in this application refers to a pulse with a pulse power above 10KW. In the above scheme, in order to ensure the discharge effect, the end of the wire connected to the coal sample 2 can be connected to the discharge electrode, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com