A magnetically controlled touch panel

A touch-pressing and plug-in technology, applied in the direction of contact parts, coupling devices, and devices for engaging/disconnecting connecting parts, etc., can solve problems such as inability to cooperate quickly, achieve easy maintenance and replacement of parts, improve safety, reduce The effect of the force released by the pull up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

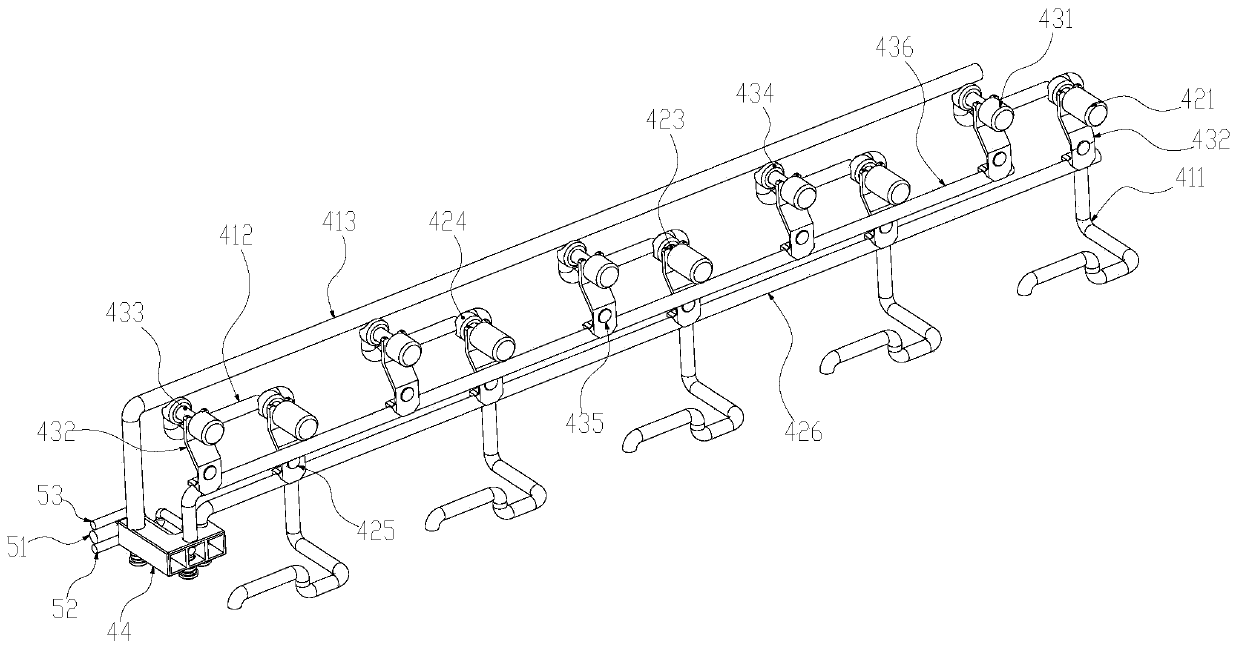

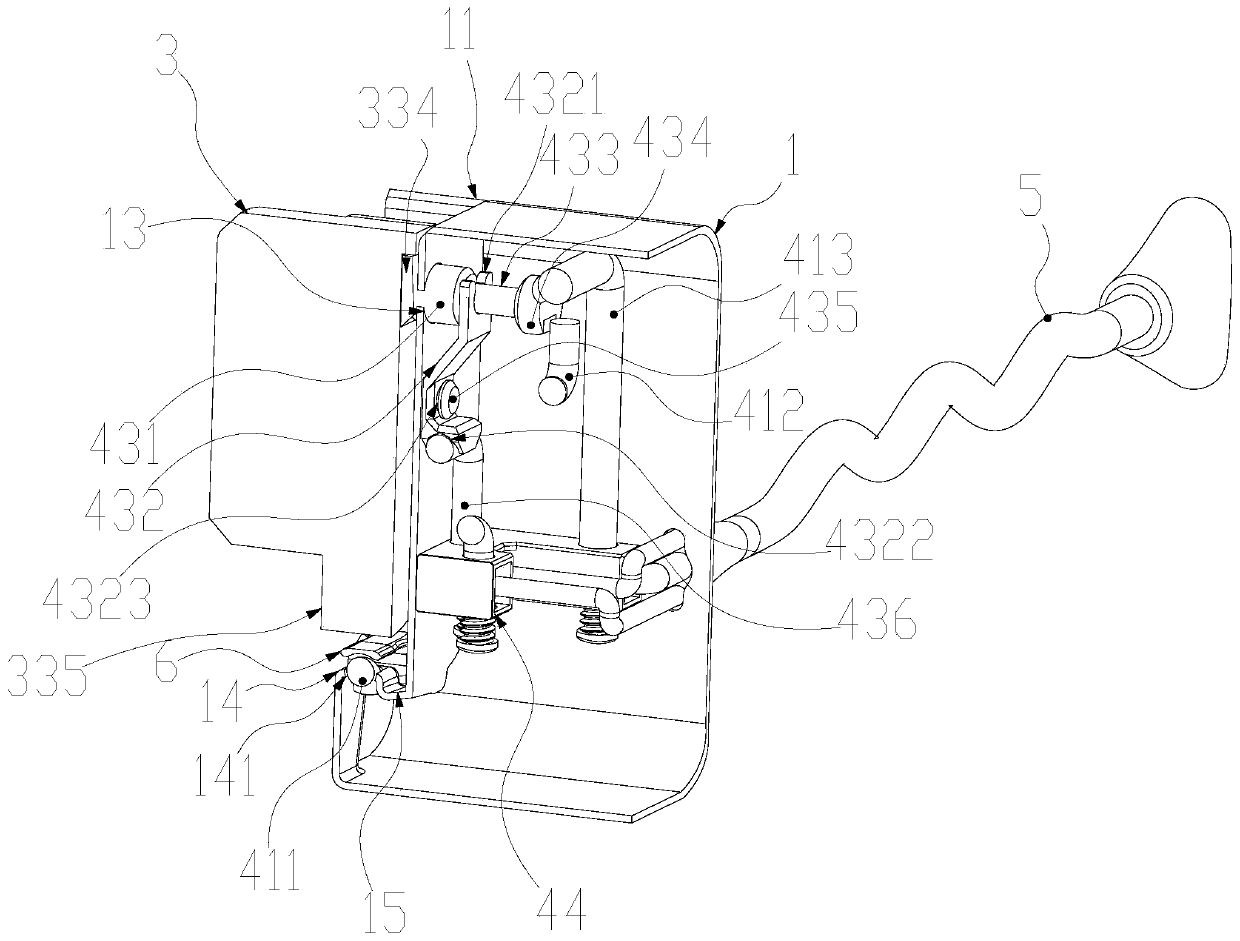

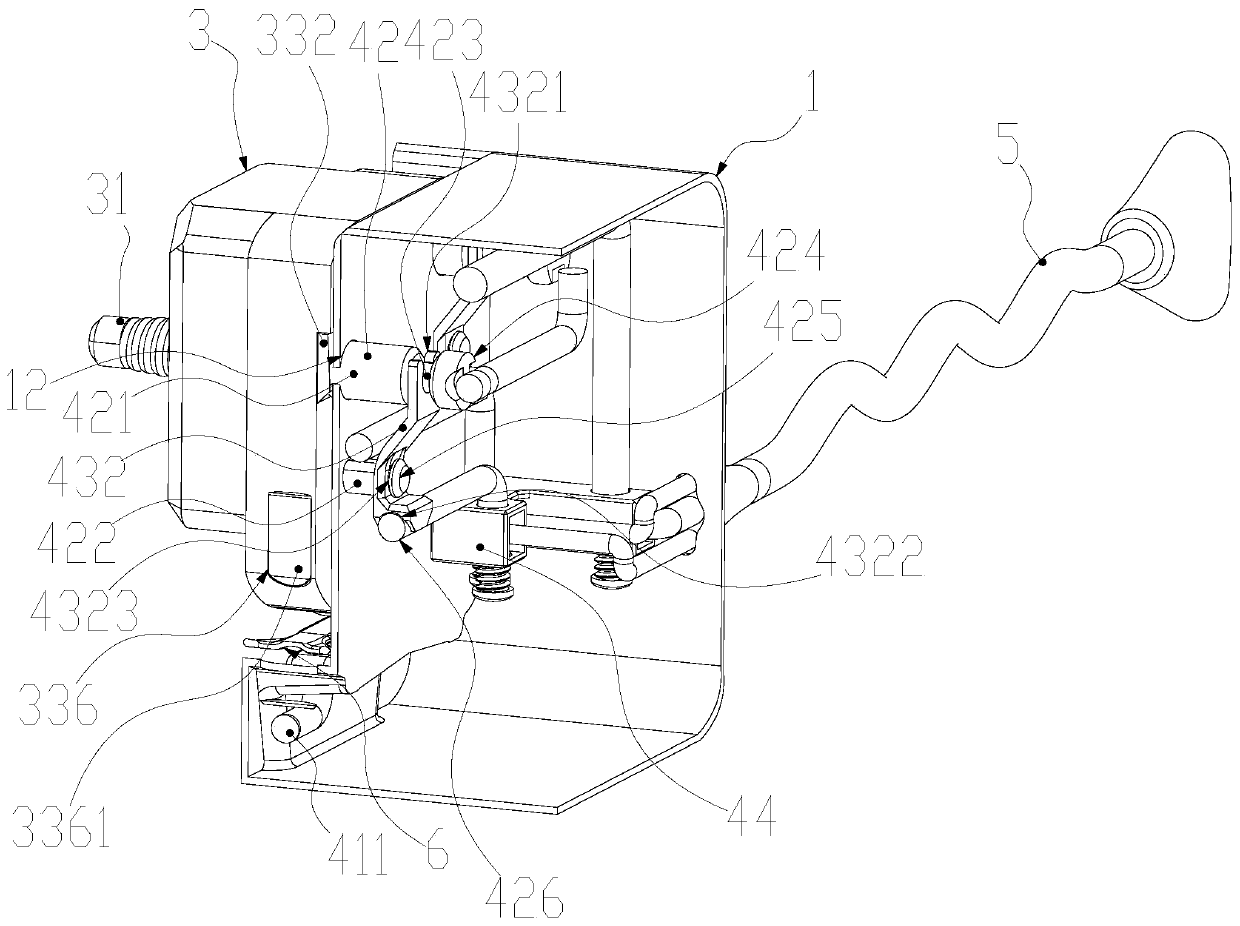

[0052] Such as Figures 1 to 12 The shown magnetic control touch-press board includes a touch-press board main body 1 , a detachable shield 2 , a circuit module 4 , a magnetic attraction module and an external connector 44 .

[0053] The main body 1 of the above-mentioned pressure contact board is composed of several slots 11 and internal installation chambers 16, and several live wire slots 141, several neutral wire through holes 12 and several A ground via hole 13.

[0054] The above-mentioned detachable guard plate 2 is fixedly fitted with the slots 11 to form insertion cavities equal in number to the slots 11 .

[0055] The above circuit module 4 includes a live wire module 41 , a neutral wire module 42 and a ground wire module 43 .

[0056] The above-mentioned circuit module 4 is placed in the internal installation chamber 16 .

[0057] In order to realize the anti-shock of the live wire, the live wire is divided into three sections, and the whole live wire can be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com