Blind hole circuit board and manufacturing method thereof

A manufacturing method and circuit board technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems affecting the thickness control of finished boards, the difficulty of controlling the copper grinding of holes, and the thickness of finished boards exceeding the standard, etc., to achieve Avoid excessive plate thickness, improve line gap production capacity, and facilitate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Embodiment: The present invention is a kind of method of making blind hole circuit board, present embodiment introduces the manufacturing method of blind hole circuit board through the blind hole circuit board that this method is made:

[0054] 1) Processing of copper clad core board

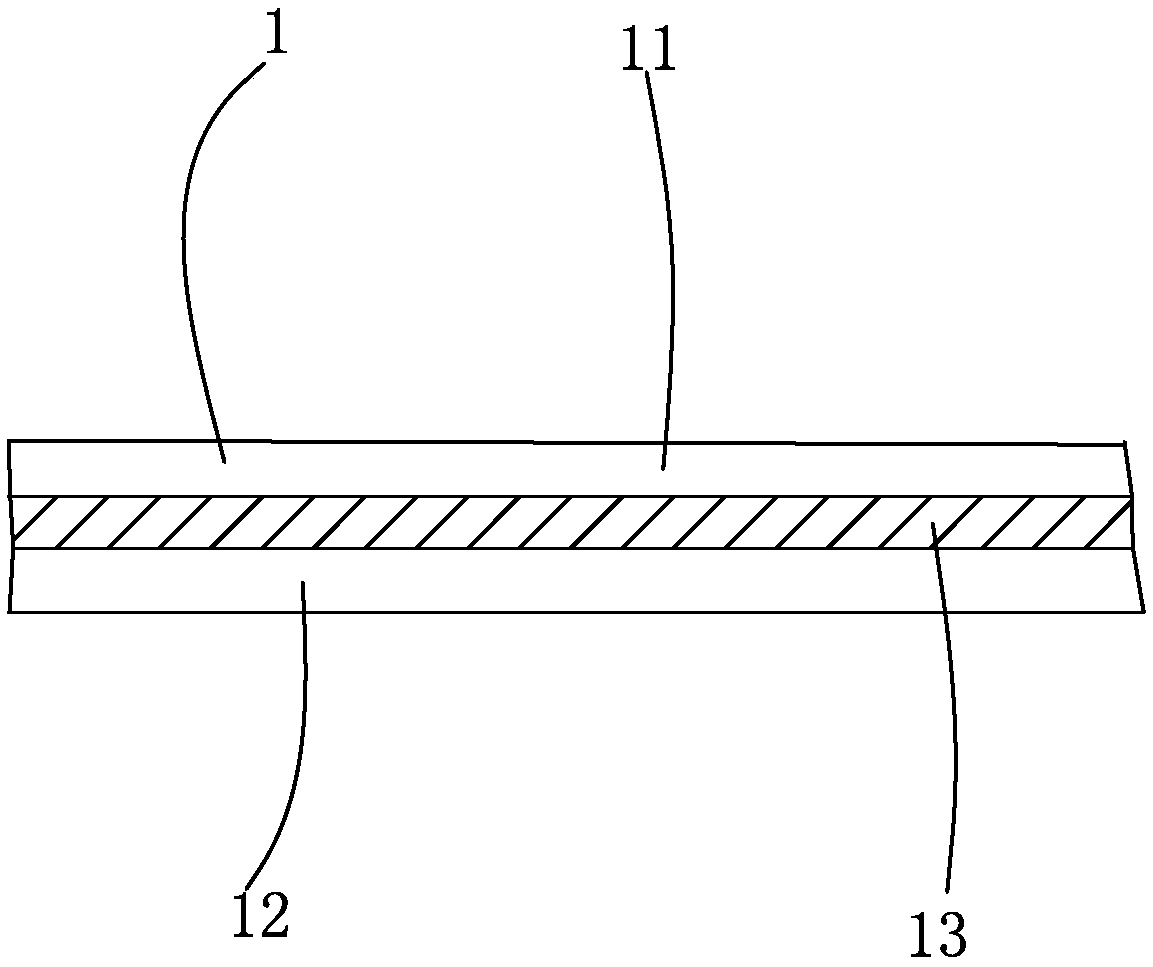

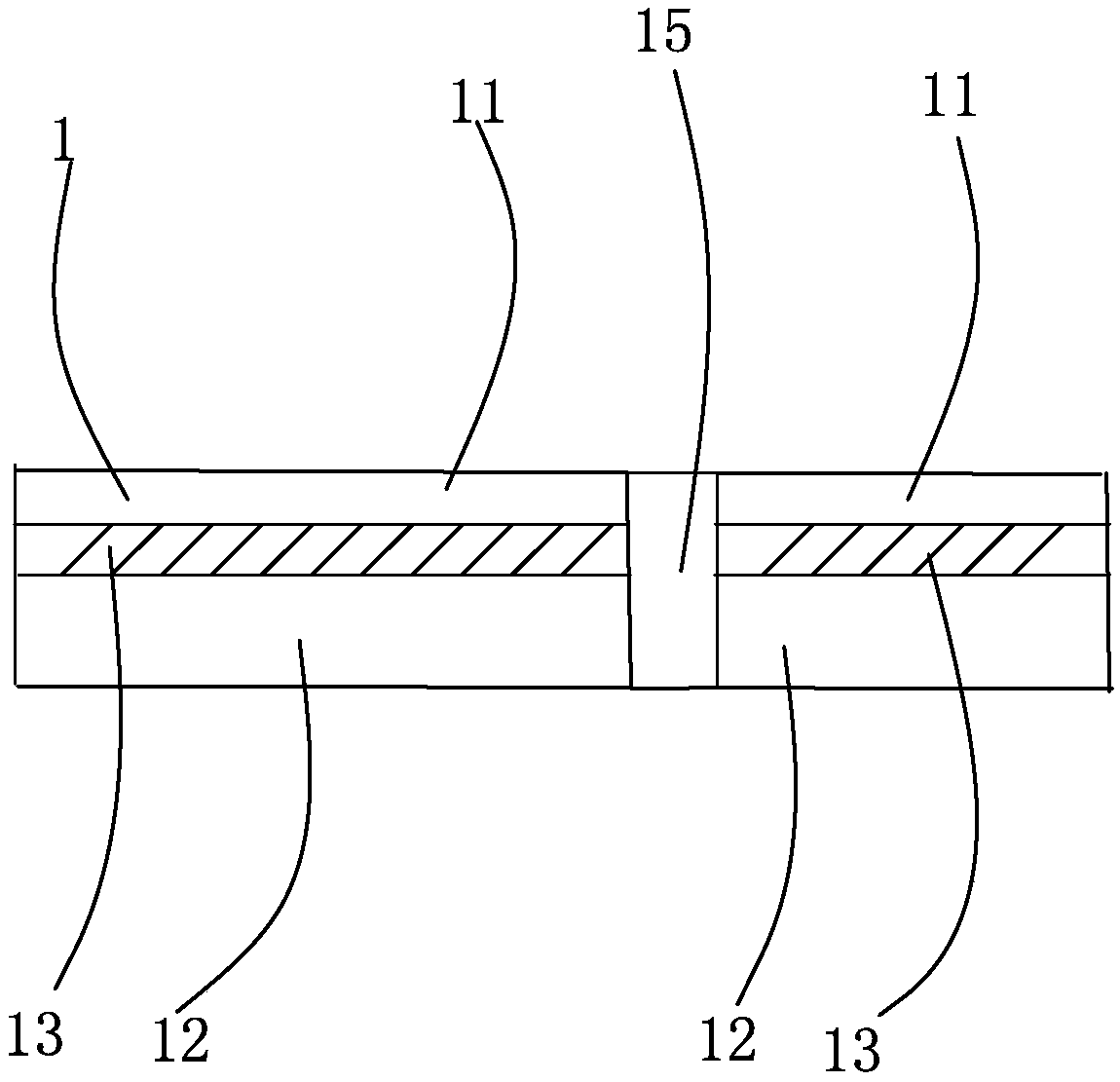

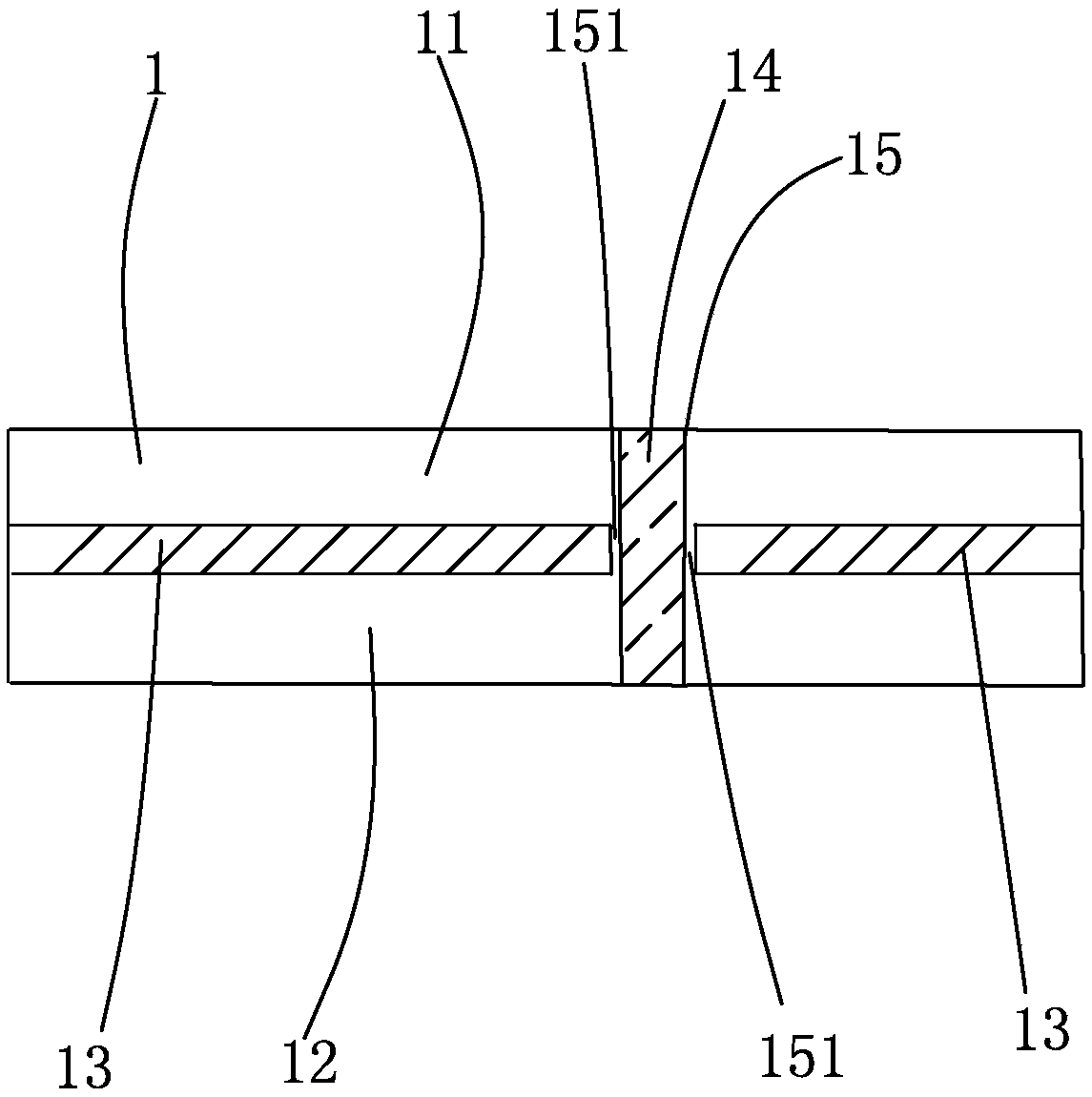

[0055] ① Select a copper-clad core board with copper foils of different thicknesses on both sides as the first copper-clad core board 1. The first copper-clad core board 1 includes a first copper foil 11 located on the first copper The core board 13 on one side of the foil 11 and the second copper foil 12 located on the other side of the core board 13, the second copper foil 12 is thickened through the plate surface electroplating process, see figure 1 Specifically, the thickness of the first copper foil 11 is 0.7mil, the thickness of the second copper foil 12 is 1.4mil, and a layer of corrosion-resistant film is made on the first layer of copper foil 11, and the second Layer copper foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com