Wall body unit capable of supporting adjustment and adjustment method of wall body unit

A technology of wall unit and adjustment method, which is applied in the direction of walls, building components, buildings, etc., to achieve the effect of making up for the space of non-standard size and convenient sliding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

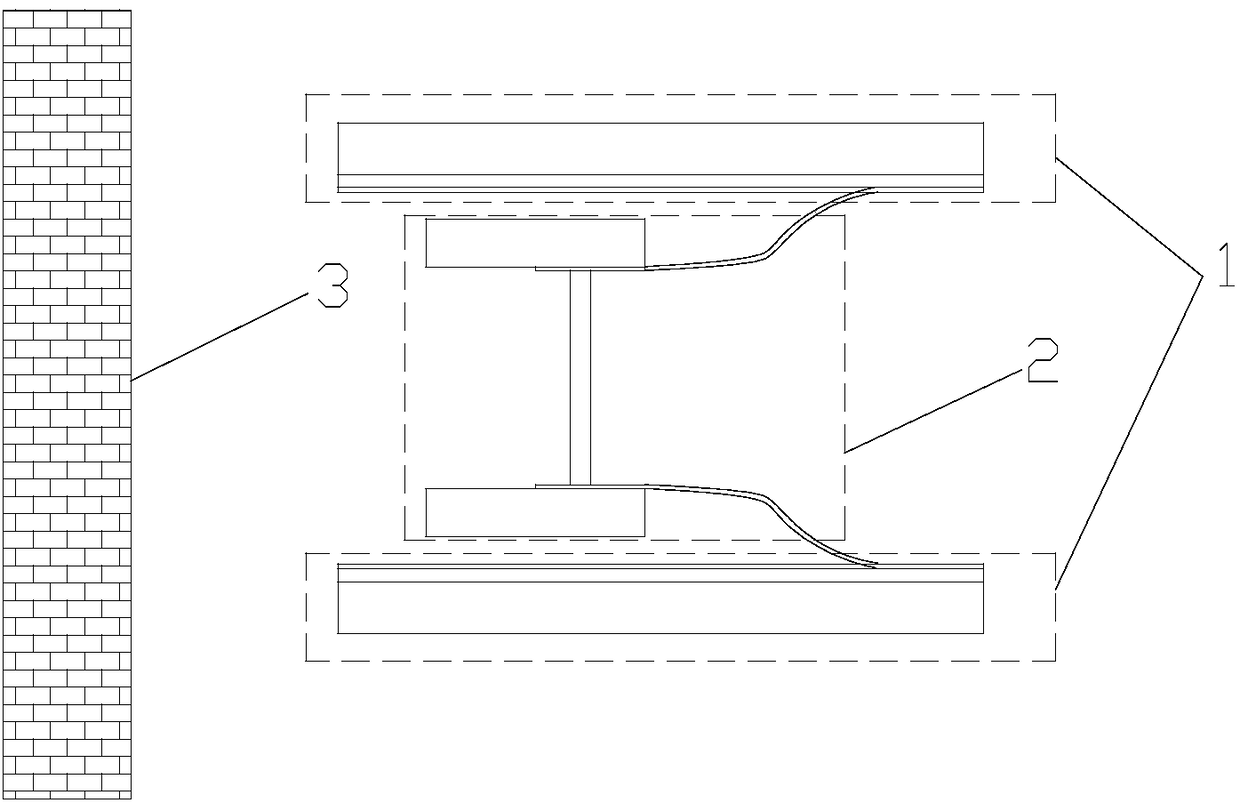

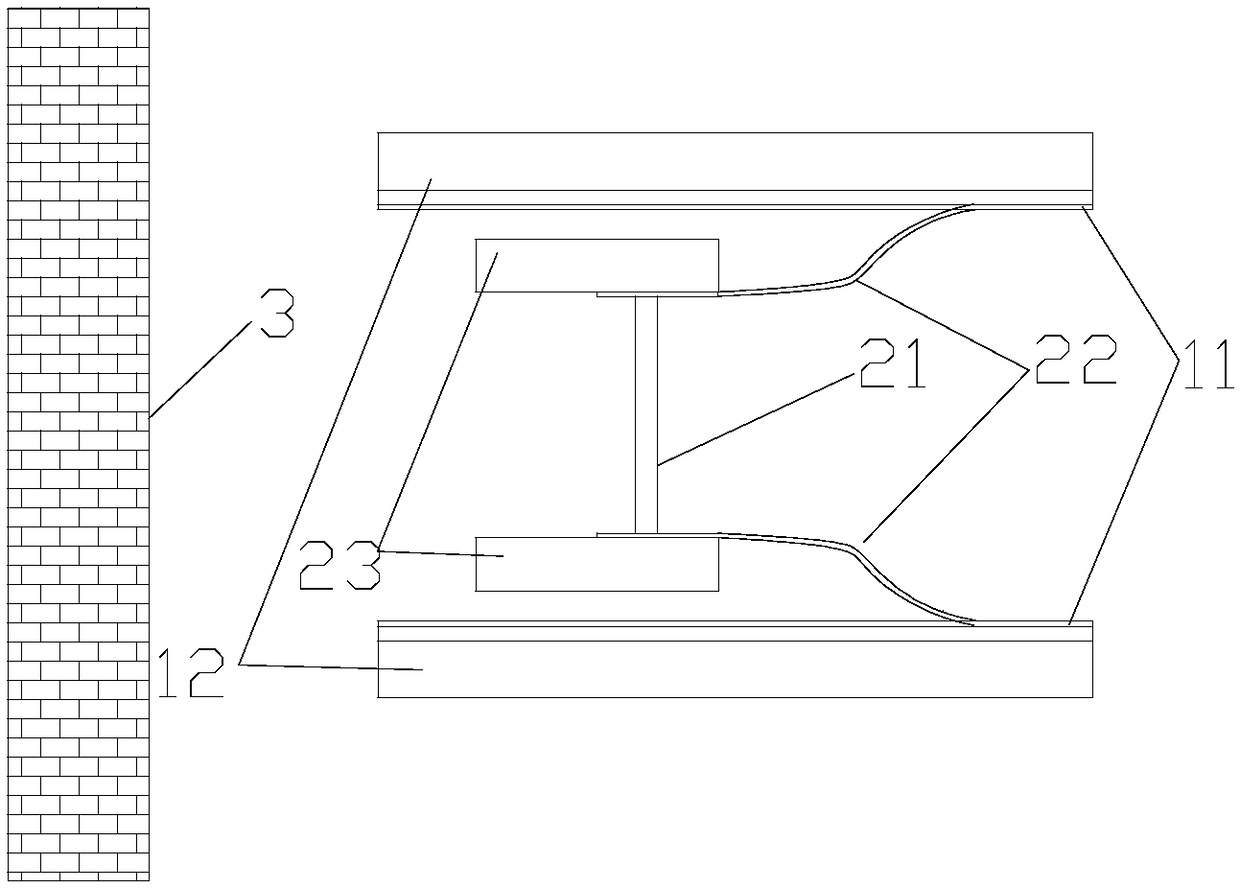

[0052] combine figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a wall unit that supports adjustment, including a fixed wall unit 1 and a sliding wall unit 2, and the sliding wall unit 2 is used to connect the fixed wall unit 1 and the wall surface of the building structure 3; Among them, the above-mentioned fixed wall unit 1 has a standard width, and a sliding unit wall of a corresponding width can be cut according to the distance between the fixed wall unit 1 and the building structure wall 3 to make up for this non-standard size space .

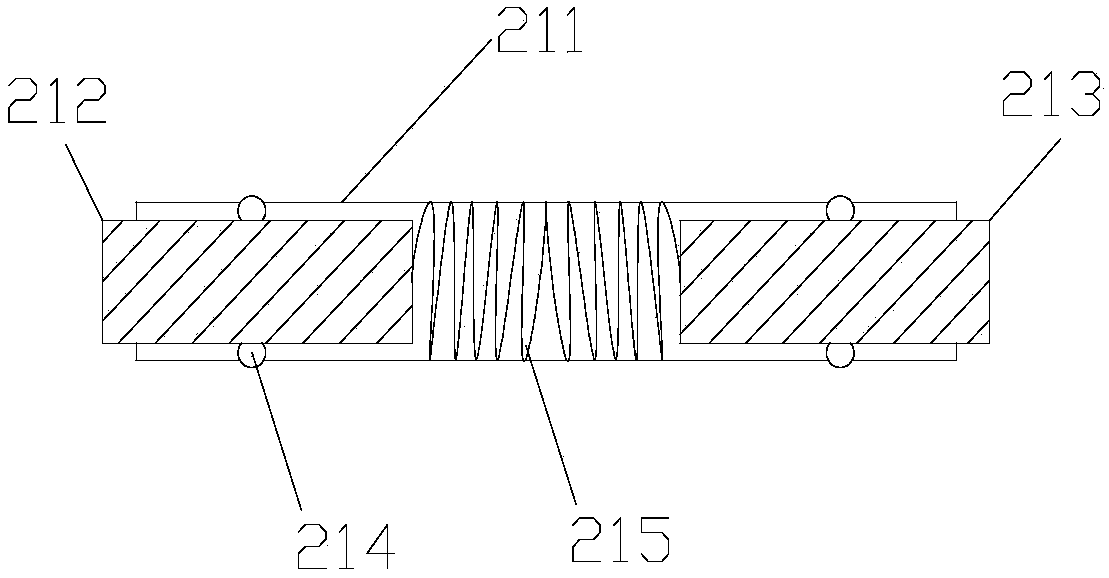

[0053] In this embodiment, the inner side of the fixed wall unit 1 is provided with a sliding track 11, the sliding wall unit 2 is arranged on the sliding track 11 through the connecting frame 22, and the sliding direction of the sliding track 11 is parallel to the gypsum of the fixed wall unit 1. Board surface direction; the inner side of the sliding wall unit 2 is also provided with telescopic support rods ...

Embodiment 2

[0075] Embodiment 2 of the present invention provides a method for adjusting the wall unit of Embodiment 1, which includes the following steps:

[0076] Step a, installing the fixed wall unit to a preset position;

[0077] Step b, such as Figure 5 Slide the sliding wall unit out from the inside of the fixed wall unit as shown; Figure 6 , Figure 7 shown, and cut off the gypsum board with a predetermined width at the end of the sliding wall unit close to the structural wall of the house; wherein, the width of the remaining gypsum board is equal to the width between the fixed wall unit and the structural wall of the house;

[0078] Step c, slide the sliding wall unit to the wall of the building structure, such as Figure 8 As shown, the two ends of the telescopic support rod 21 extend outwards so that the plasterboard surface of the sliding wall unit is flush with the plasterboard surface of the fixed wall unit.

[0079] combine Figure 6 , Figure 7 As shown, the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com