Mounting technology of fireproof non-deformable light steel curtain box

An installation process and curtain box technology, applied in the field of curtain boxes, can solve problems such as difficulty in popularization and application, high maintenance rate, and base layer bending, and achieve the best promotion and application value, exquisite installation, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

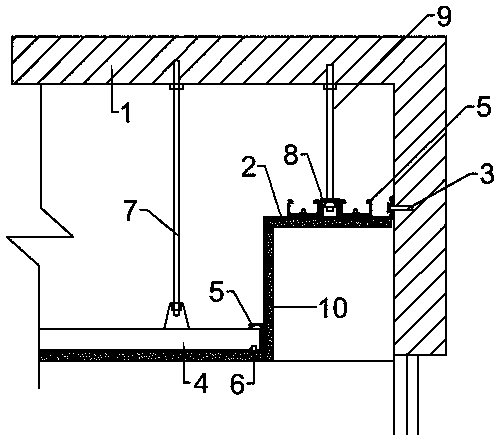

[0023] see figure 1 , a kind of installation process of fireproof and non-deformable light steel curtain box, comprising the following steps:

[0024] Step 1. Horizontal positioning and lofting: according to the ceiling elevation, position the horizontal fixed point and the 9 fixed points of the limit-foot hanging rib;

[0025] Step 2, installation of the length-limiting hanging bars 9: fixedly install the length-limiting hanging bars 9 on the top of the wall 1;

[0026] Step 3: After the box body 2 has been leveled and adjusted, fix the box body 2 on the side wall of the wall body 1 with US solid nails 3;

[0027] Step 4, screwing the bottom of the ruler-limiting rib 9 to the U-shaped lining 8 arranged on the upper side of the box body 2;

[0028] Step 5, two auxiliary keels 5 are installed symmetrically on the left and right sides of the U-shaped lining 8;

[0029] Step 6, fix the edge keel 4 and the auxiliary keel 5 through rivets 6;

[0030] Step 7: Fix and connect the...

Embodiment 2

[0034] see figure 1 , the upper part of the box body 2 is fixedly provided with a U-shaped lining 8, and the upper side of the U-shaped lining 8 is threaded to be connected with the limit-foot hanging rib 9, and the bottom of the limit-foot hanging rib 9 is threadedly connected with the U-shaped lining 8, and the limit-foot hanging rib 9 The top is fixedly connected with the top of the wall 1; two auxiliary keels 5 are symmetrically arranged on the left and right sides of the U-shaped lining 8, and the lower sides of the box body 2 and the edge keels 4 are connected with gypsum boards 10 by drywall nails. Compared with the traditional wood-based base, the present invention has better fireproof performance, and because the U-shaped backing 8 is provided, it plays a further reinforcing role. After long-term use, its deformation is small, so the use effect is better Good, with a wider range of promotion and application value.

[0035] The width and height of the U-shaped lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com