Pipe-laying installation device for jacking construction of concrete bell and spigot pipes

An installation device and jacking technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of pipeline installation quality can not be guaranteed, pipelines are easily deflected, and pipeline sealing is damaged , to achieve the effect of ensuring straightness and standardization, low labor intensity and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

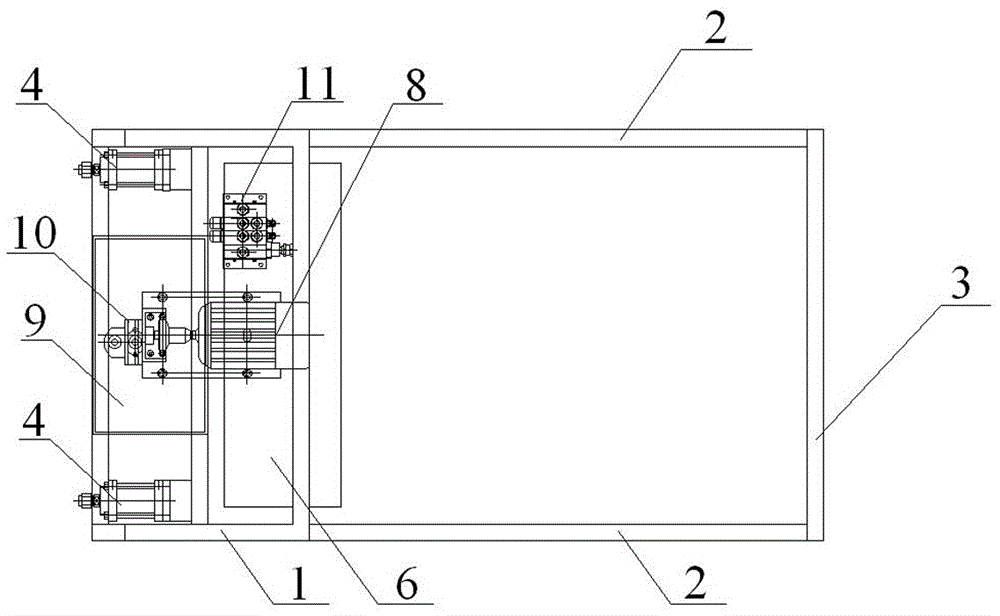

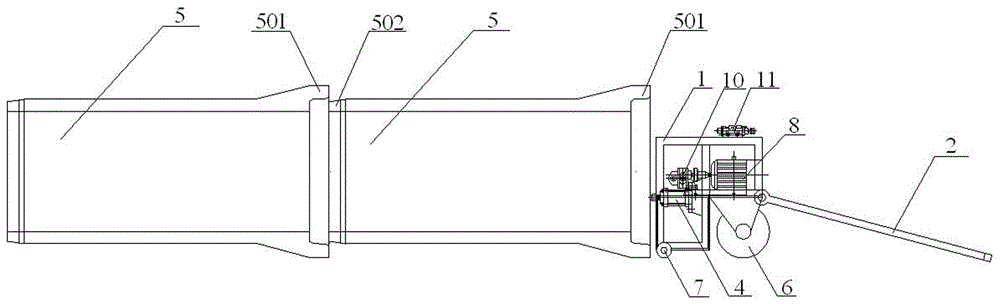

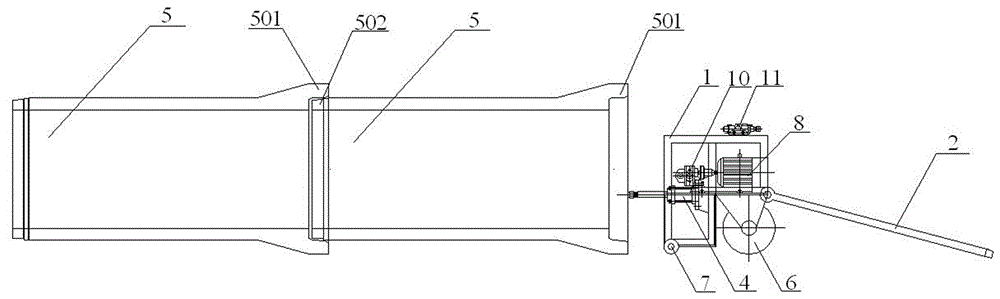

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] A pipe installation device for concrete socket pipe jacking construction, comprising a frame 1, a walking wheel set installed at the bottom of the frame 1, a hydraulic propulsion mechanism arranged on the frame 1, and a frame hinged at the rear end of the frame 1 Push rod assembly, travel wheel set comprises travel wheel 6 and auxiliary wheel 7, wherein, travel wheel 6 is arranged on frame 1 near one end of push rod assembly, and auxiliary wheel 7 is arranged on frame 1 end away from push rod assembly, and travel wheel 6 and the number of auxiliary wheels 7 are two, and the diameter of the traveling wheel 6 is greater than the diameter of the auxiliary wheels 7, and the bottom of the frame 1 is also installed to limit the positions of the traveling wheels 6 and the auxiliary wheels 7 the locking device.

[0023] The push rod assembly includes two rear seat pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com