Optical imaging system

An optical imaging system and optical axis technology, applied in the field of optics, can solve the problems of imaging quality and miniaturization design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

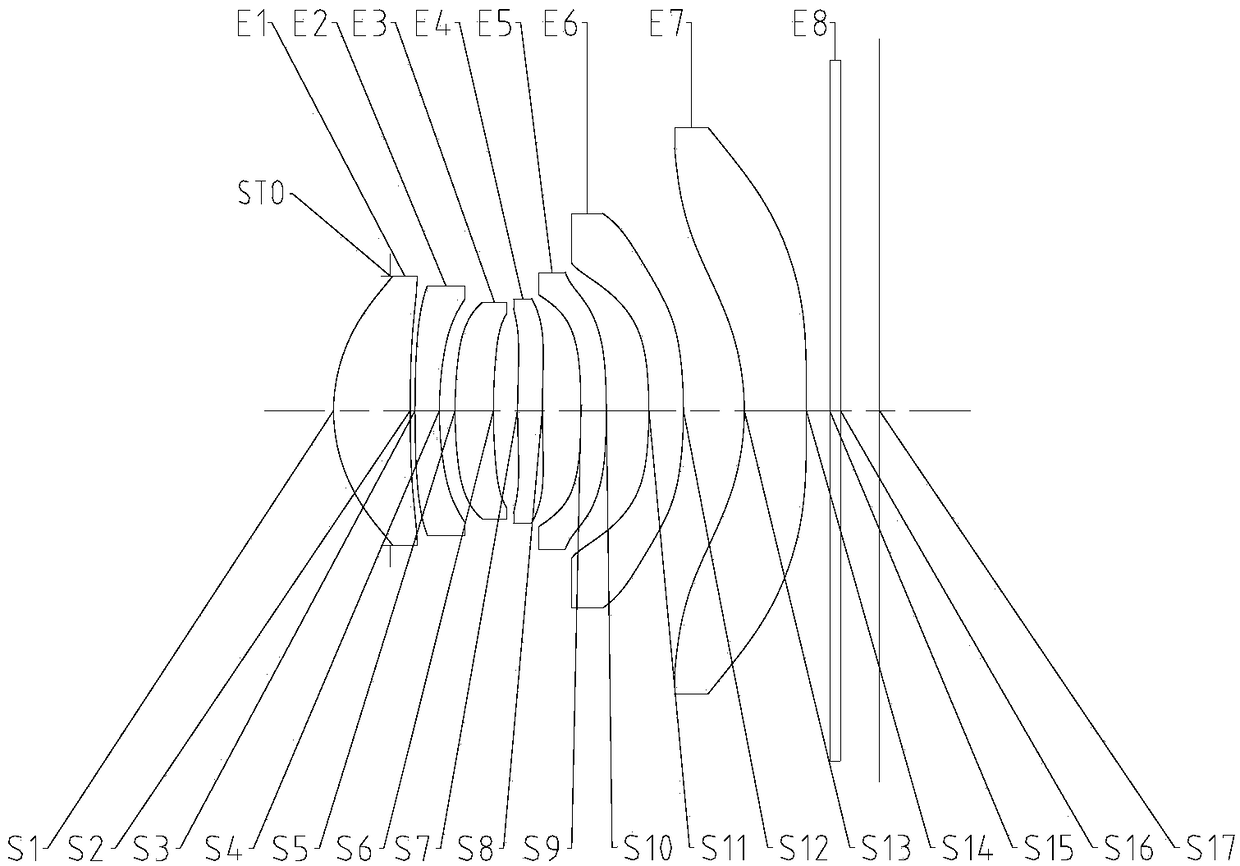

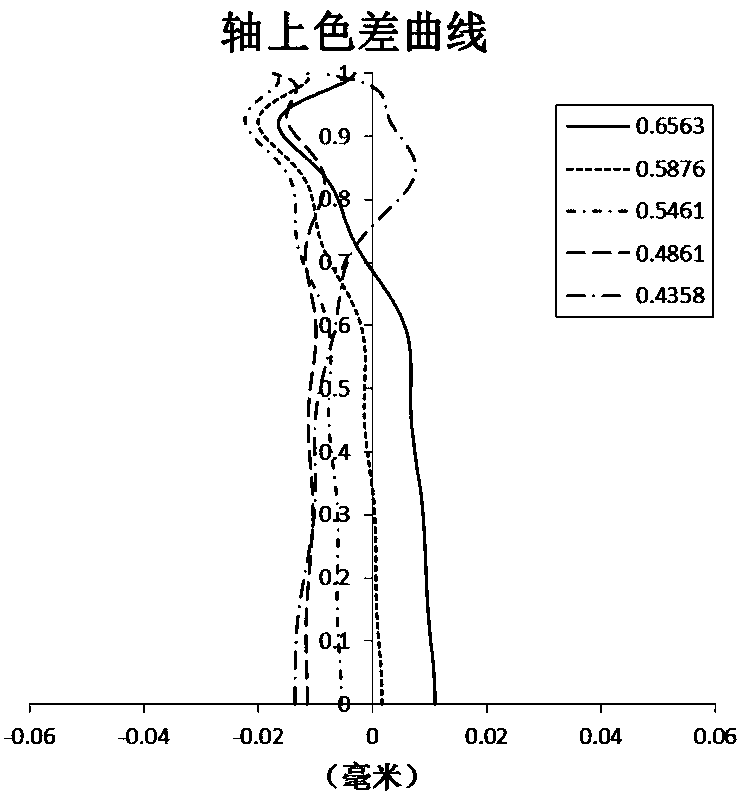

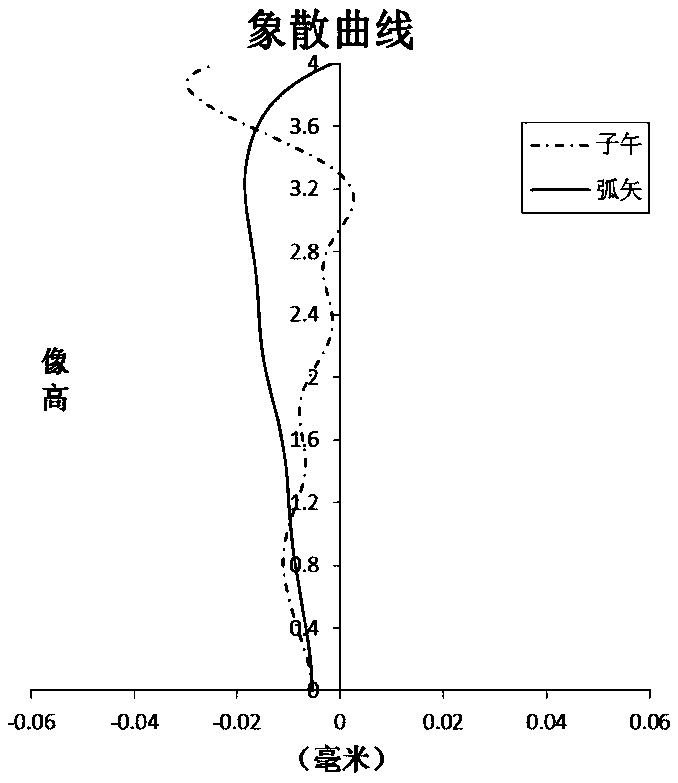

[0060] like figure 1 As shown, along the direction from the object side to the image side along the optical axis, the optical imaging system sequentially includes a stop STO, a first lens E1, a second lens E2, a third lens E3, a fourth lens E4, and a fifth lens E5 , the sixth lens E6, the seventh lens E7, the filter E8 and the imaging surface S17.

[0061] The first lens has positive refractive power, and the object side of the first lens is convex and aspheric, and the image side is concave and aspherical; the second lens has negative refractive power, and the object side of the second lens is Convex and aspheric, the image side is concave and aspheric; the third lens has positive power, and the object side of the third lens is convex and aspheric, and the image side is concave and aspherical; The fourth lens has positive refractive power, and the object side of the fourth lens is convex and aspherical, and the image side is concave and aspheric; the fifth lens has negative ...

Embodiment 2

[0078] like image 3 As shown, along the direction from the object side to the image side along the optical axis, the optical imaging system sequentially includes a first lens E1, a second lens E2, a third lens E3, a fourth lens E4, a fifth lens E5, and a sixth lens E6, seventh lens E7, filter E8 and imaging surface S17.

[0079] The first lens has positive refractive power, and the object side of the first lens is convex and aspheric, and the image side is concave and aspherical; the second lens has negative refractive power, and the object side of the second lens is Convex and aspheric, the image side is concave and aspheric; the third lens has positive power, and the object side of the third lens is convex and aspheric, and the image side is concave and aspherical; The fourth lens has positive refractive power, and the object side of the fourth lens is convex and aspherical, and the image side is concave and aspheric; the fifth lens has positive refractive power, and the o...

Embodiment 3

[0094] like Figure 5 As shown, along the direction from the object side to the image side along the optical axis, the optical imaging system sequentially includes a first lens E1, a second lens E2, a diaphragm STO, a third lens E3, a fourth lens E4, and a fifth lens E5 , the sixth lens E6, the seventh lens E7, the filter E8 and the imaging surface S17.

[0095] The first lens has positive refractive power, and the object side of the first lens is convex and aspheric, and the image side is concave and aspherical; the second lens has negative refractive power, and the object side of the second lens is Convex and aspheric, the image side is concave and aspheric; the third lens has positive power, and the object side of the third lens is convex and aspheric, and the image side is concave and aspherical; The fourth lens has positive refractive power, and the object side of the fourth lens is convex and aspherical, and the image side is concave and aspheric; the fifth lens has pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com