Fiber electric brush assembly

A brush and fiber technology, applied in the direction of circuits, collectors, electrical components, etc., can solve the problems of complex assembly structure of fiber brushes, high requirements for fine workmanship of fiber brushes, and general fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

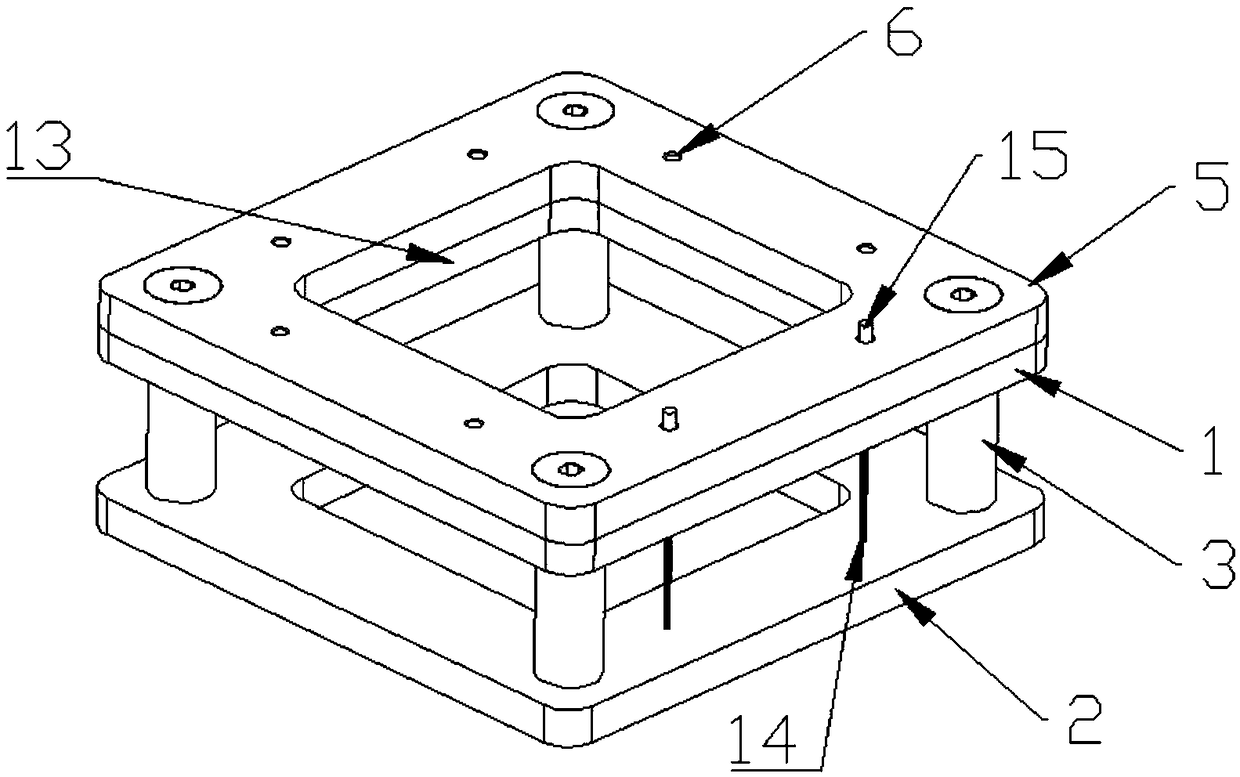

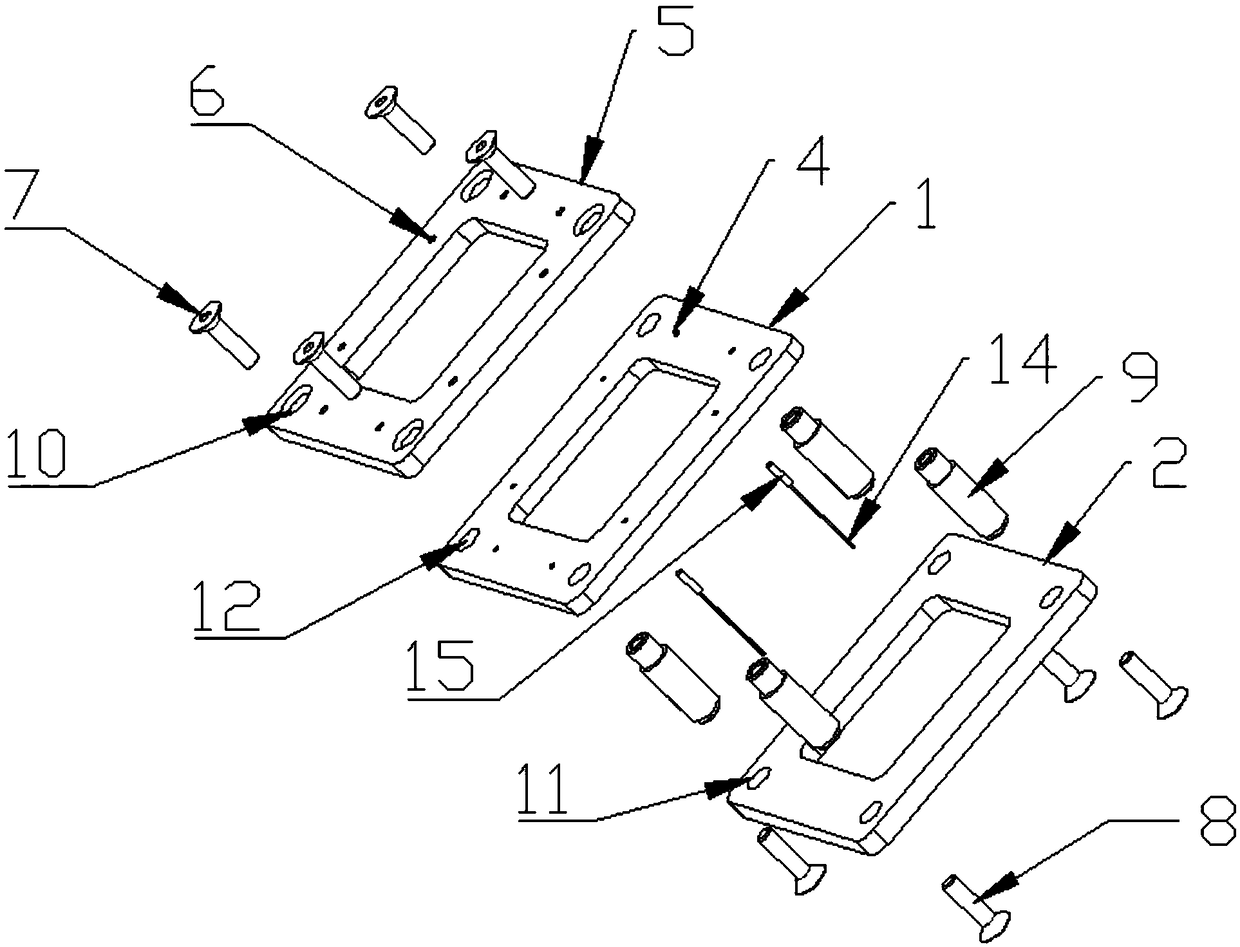

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as figure 1 , 2 As shown, the present invention provides a fiber brush assembly, the fiber brush includes a fiber bundle 14 and a fiber bundle copper tube 15, the fiber brush assembly includes a positioning plate 1, a bottom plate 2 and a support column 3, the positioning plate 1 Located above the base plate 2, the lower end of the supporting column 3 is fixed on the base plate 2, the positioning plate 1 is fixed on the upper part of the supporting column 3, the positioning plate 1 is provided with a limiting hole 4 for limiting the fiber bundle 14, The outer diameter of the fiber bundle copper tube 15 is larger than the diameter of the limiting hole 4 . When such a fiber brush is assembled in use, the fiber bundle copper tube 15 is first placed above the limit hole 4, and the through hole 12 of the same light is aligned with the limit hole 4, and then the fib...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap