A special bracket suitable for material detection of shaft pins in substations

A shaft pin and material technology, applied in the field of shaft pin material detection structure improvement, can solve problems affecting power safety, rust, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described in detail through the following examples, but the technical content described in this example is illustrative rather than limiting, and should not limit the protection scope of the present invention accordingly.

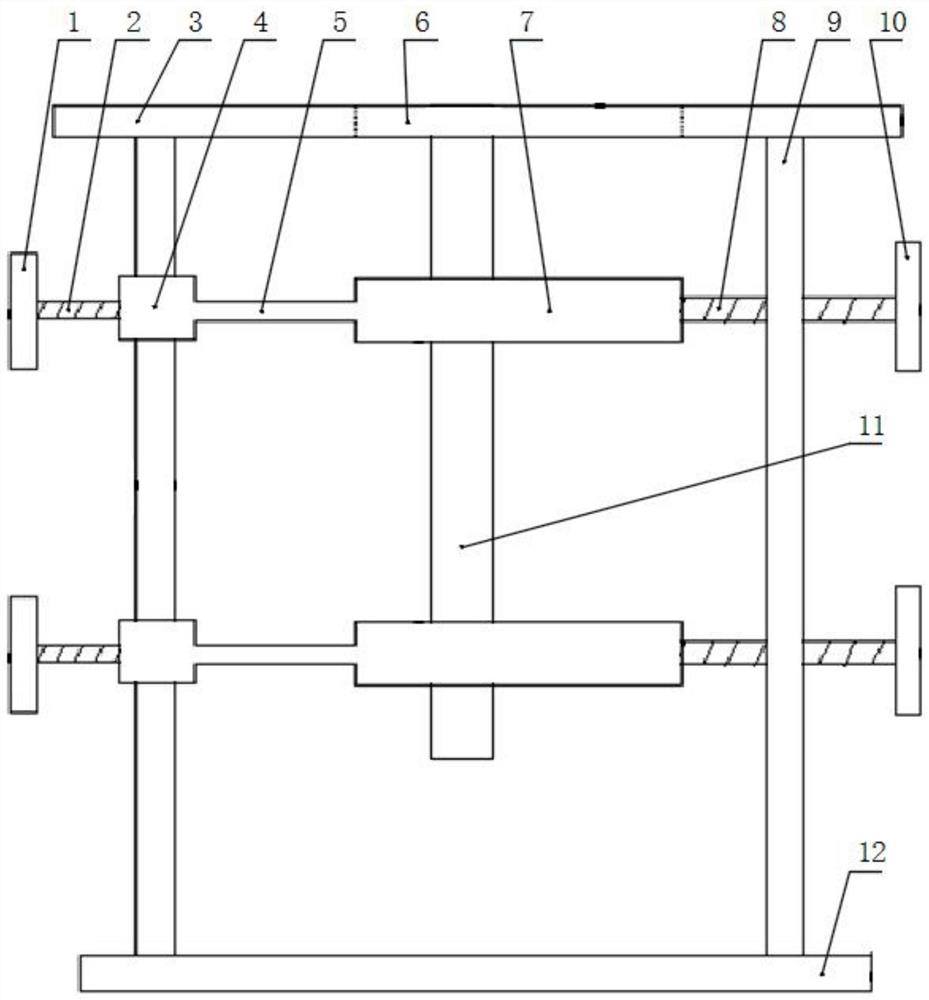

[0012] A special bracket suitable for substation shaft pin material detection, such as figure 1 As shown, the innovation of the present invention lies in: comprising base plate 12, panel 3, support column 9 and fixing mechanism, panel and base plate vertical direction are arranged at intervals, a plurality of support columns are set between the two, the vertical direction of a support column Two fixing mechanisms that can vertically slide are arranged at intervals, and the two fixing mechanisms can clamp the shaft pin 11 to be detected.

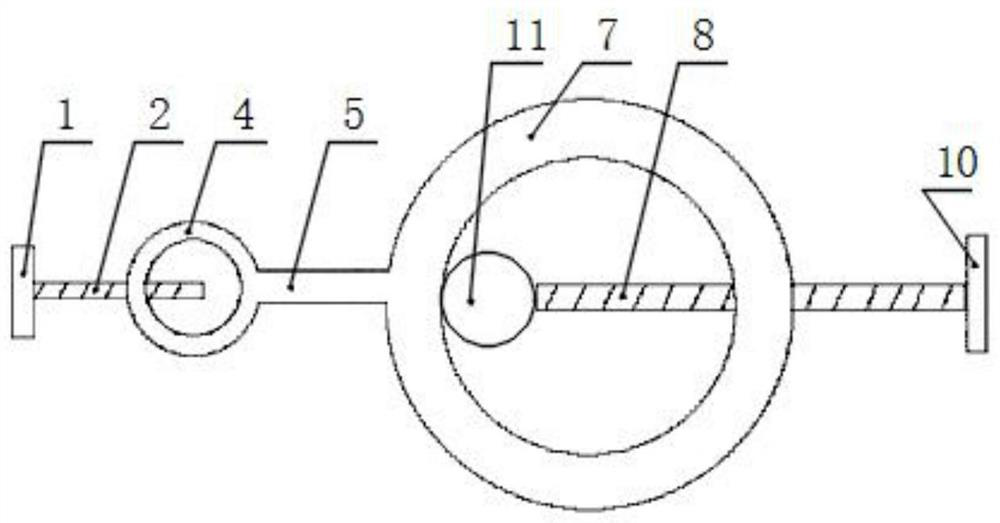

[0013] In this embodiment, the fixing mechanism such as figure 2 As shown, it includes a sliding end 4 and a clamping ring 7. The sliding end vertically slides on the outer edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com