Method and device for controlling maximum output load of unit

A technology with maximum output and load control, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., it can solve problems such as poor user comfort, no solution proposed, frequent switching of units, etc., to reduce workload and improve Use comfort, improve the effect of use comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0049] Considering that the maximum output load of the existing units is set before leaving the factory, professionals are required to set it up during operation. If the maximum output load is set too low or too high, it will affect the comfort of users.

[0050] In this example, a method for controlling the maximum output load of the unit is provided, such as figure 1 As shown, the following steps may be included:

[0051] Step 101: Obtain the actual load demand on the unit;

[0052] Step 102: Control the maximum load value of the unit according to the actual load demand.

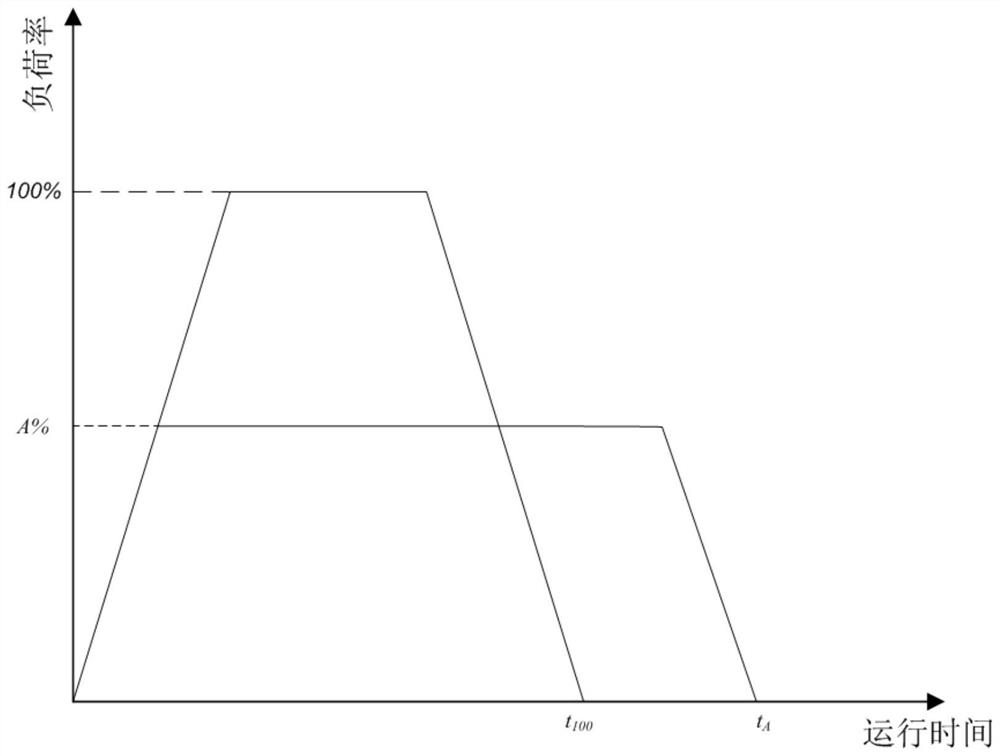

[0053] In the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com