Socket that can be assembled and combined

A socket and socket body technology, which is applied to the parts of the connection device, the coupling device, the two-part connection device, etc., can solve the problems of poor connection effect, large area of the plug board, and occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

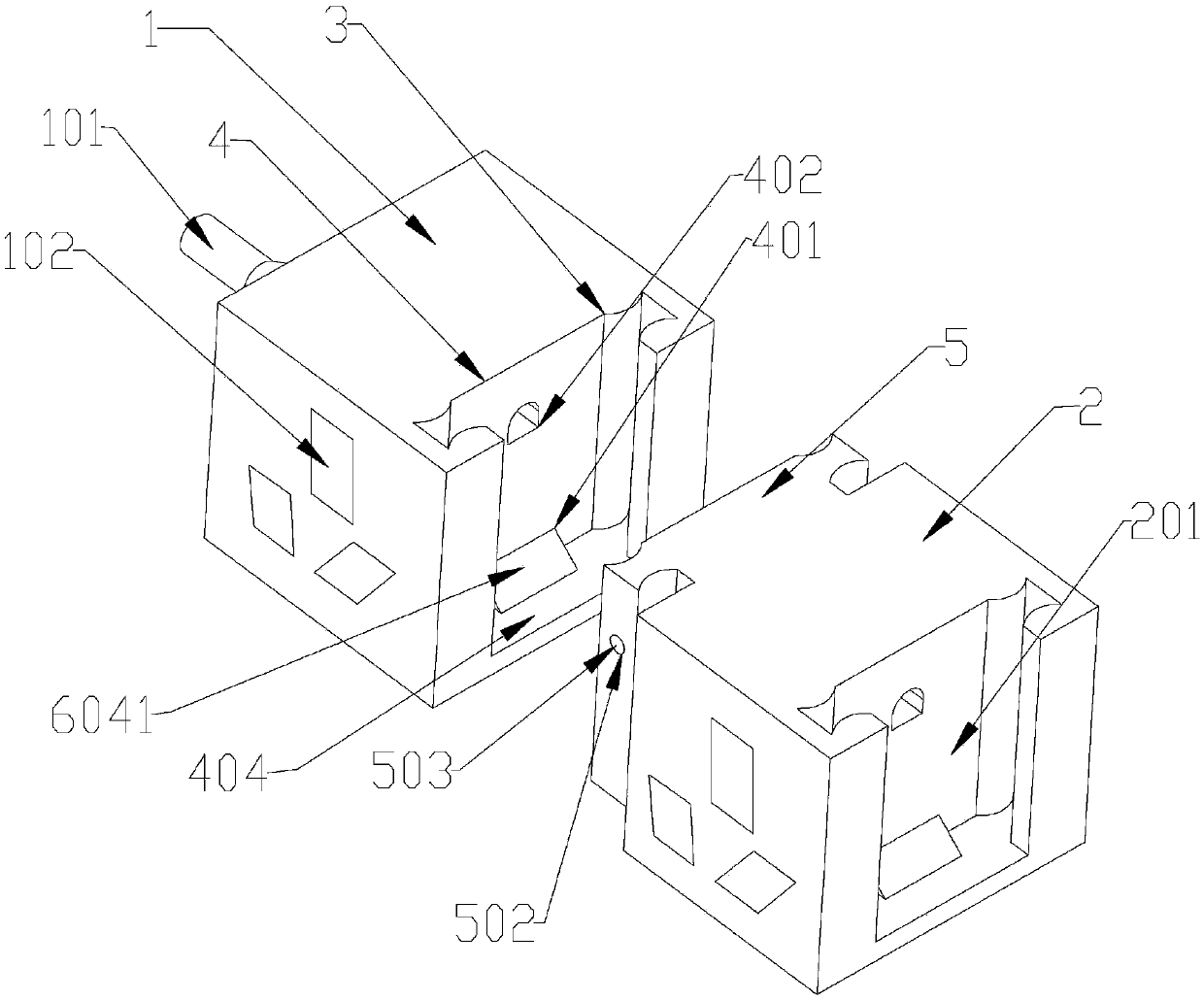

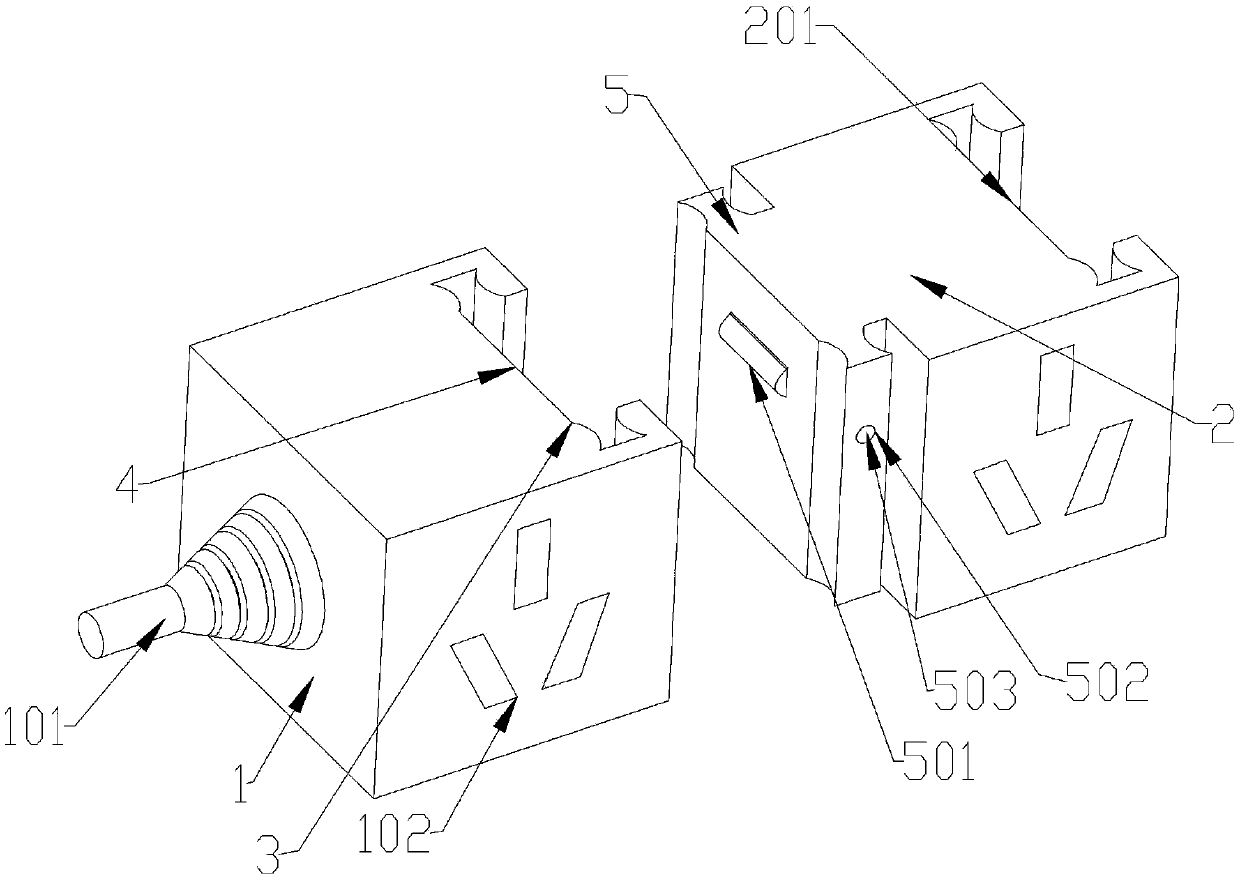

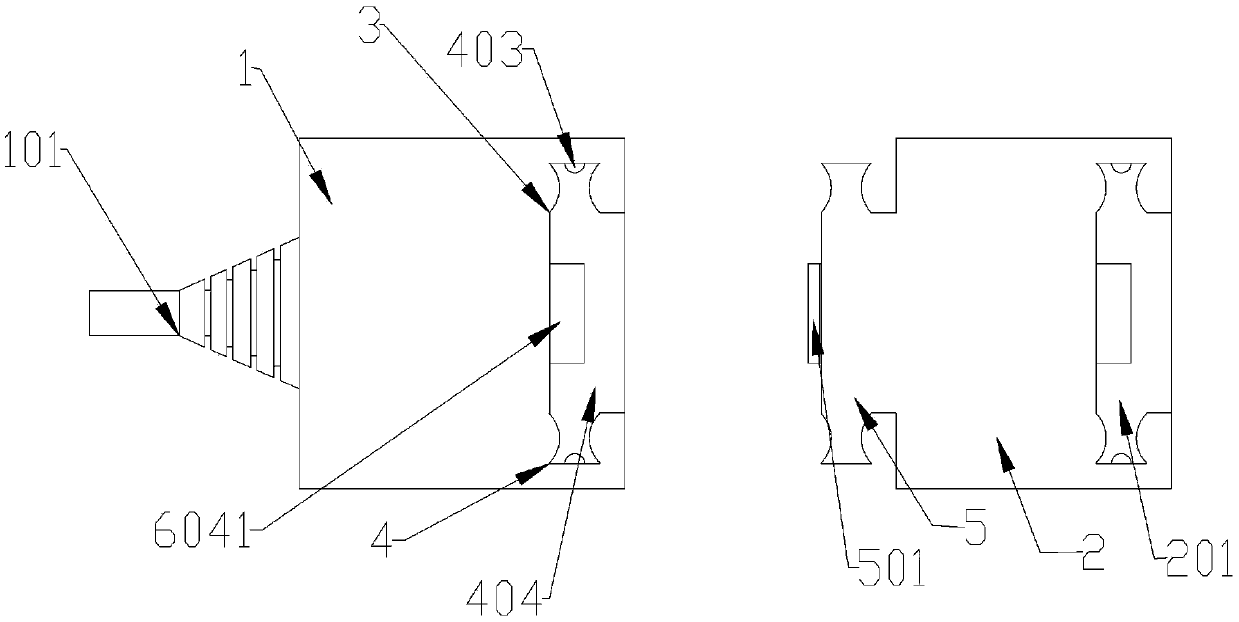

[0022] Example 1: see Figure 1 to Figure 6After the applicant embeds the first protrusion in the chute, the outer side wall of the lower end of the first protrusion will be pressed to the second protrusion protruding from the inner side wall of the chute, because the second protrusion protrudes from the inner side wall of the chute It is an oblique structure, so when the lower end of the first protrusion is pressed against the oblique structure of the second protrusion, the second protrusion will slide into the second cavity due to being squeezed, thereby pushing the second The connecting rod squeezes the first spring, and because the lower end of the first connecting rod is connected to the second connecting rod through the second rotating shaft, so when the second connecting rod moves toward the first spring, the lower end of the first connecting rod also moves toward the first spring. The direction of the spring is inclined. Since the center of the first connecting rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com