Magnetic steel distribution device

A material distributing device and magnetic steel technology, applied in the field of workpiece material distributing, can solve the problems of applicability and practicability limitations, affecting the efficiency and quality of material distributing, and the inability to divide material of workpieces, etc., to achieve good practicability, Reasonable structure setting, the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

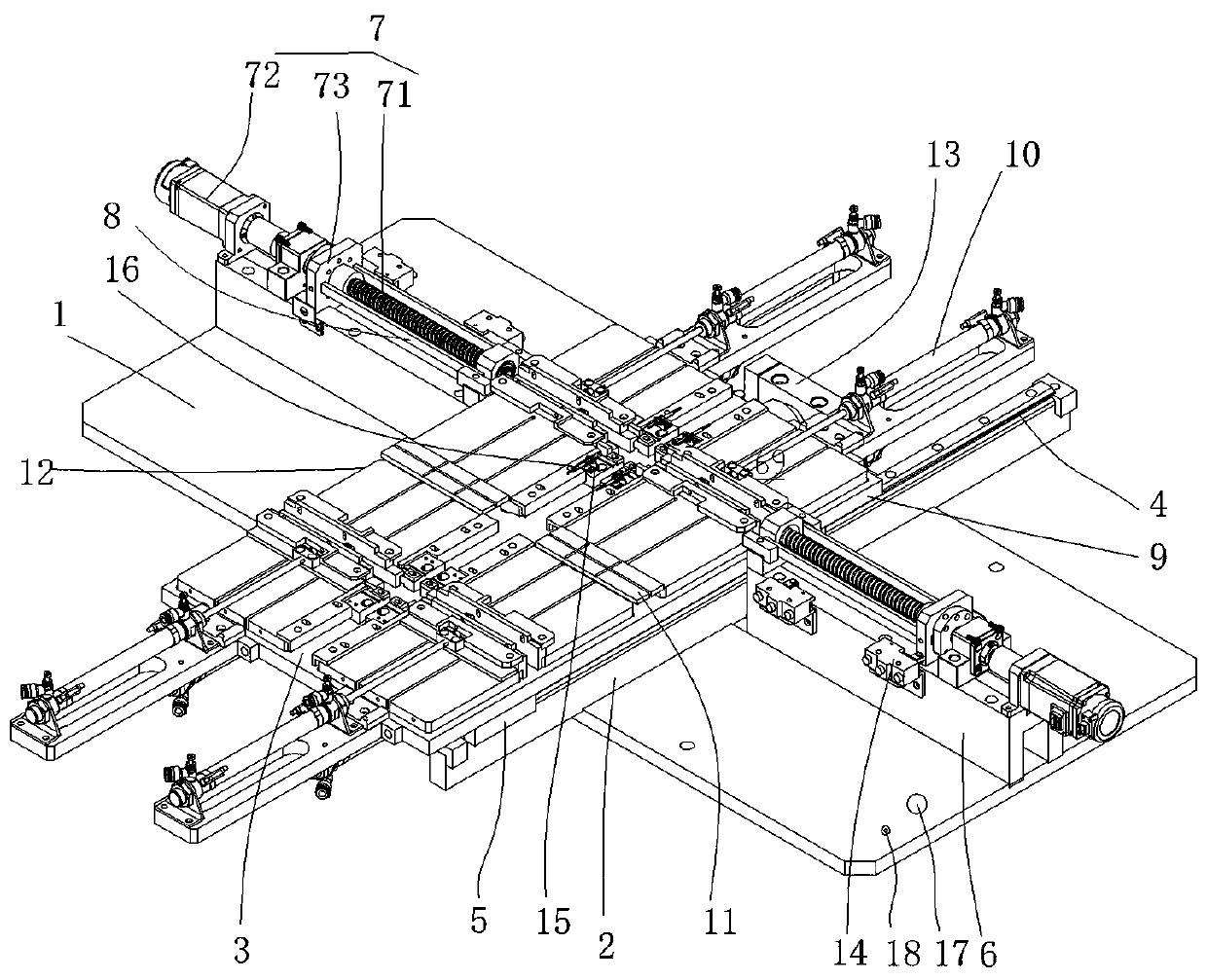

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a magnetic steel material distribution device, comprising a material distribution platform 1, two parallel slide rail mounting plates 2 are arranged in the middle of the material distribution platform, and a feeding channel is arranged between the two slide rail mounting plates 2 Groove 3, a slide rail 4 is arranged on the slide rail mounting plate, a slider 5 is arranged in the slide rail, and two screw mandrel modules on the same straight line are also arranged on the material distribution platform Bottom plate 6, screw mandrel module 7 is arranged on described screw mandrel module bottom plate, is fixed with distribution push rod 8 on described screw mandrel module, the connecting line of described screw mandrel module bottom plate and described slide The rail mounting plate is vertical and is on the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com