Electrostatic-to-pneumatic converter

An air pressure conversion and converter technology, which is applied in physical quantity changers, fluid pressure actuation devices, valve details, etc. It can solve the problem of not being able to change the pressure at the outlet, and achieve good vibration resistance, acceleration insensitivity, and stable response. The effect of improving sexuality, improving response performance and stabilizing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

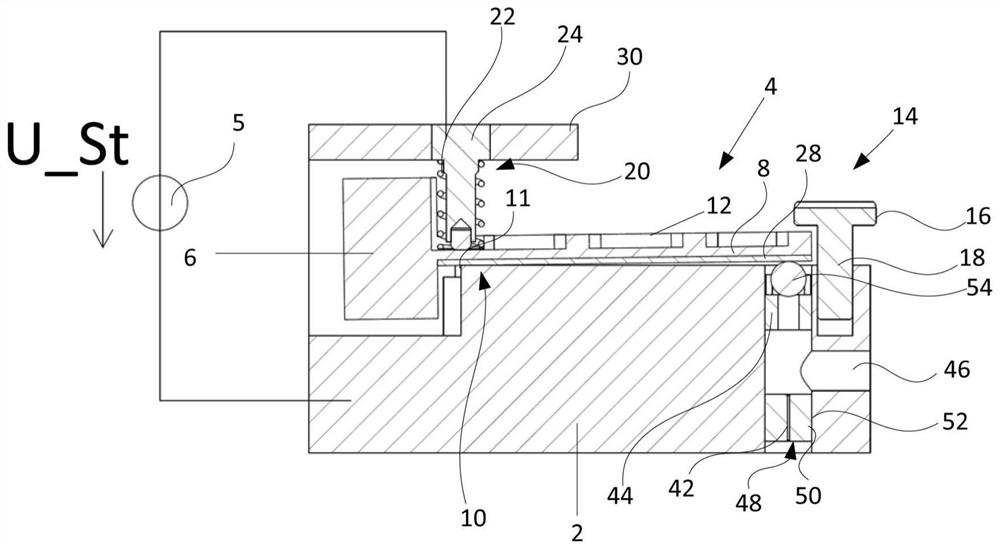

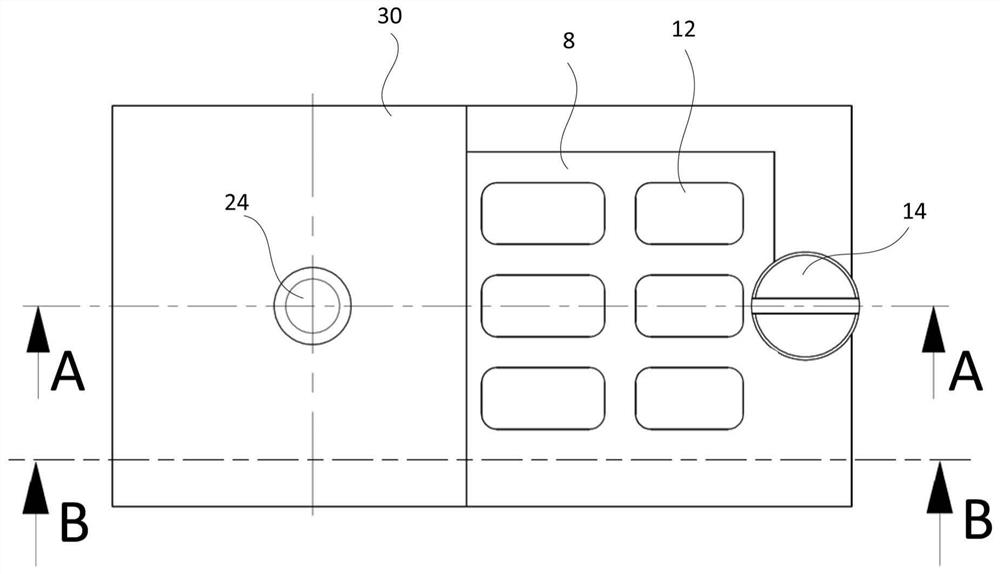

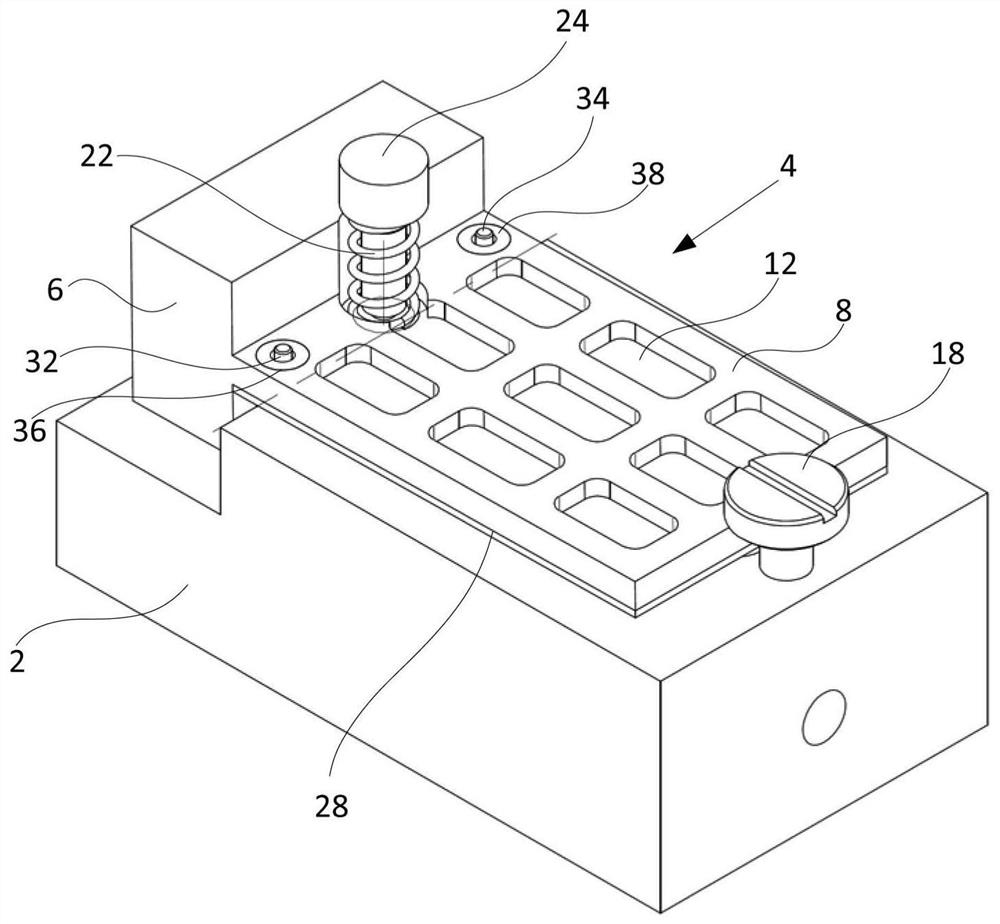

[0059] figure 1 shows along the figure 2 A cross-sectional view of the line A-A, figure 2 shows the basis figure 1 A top view of the electrostatic-pneumatic converter. according to figure 1 The electrostatic-pneumatic converter thus comprises an electrostatic control device comprising a ground electrode 2 and a control electrode 4 designed to be electrically insulated from the ground electrode 2 in the form of a movable equal-arm balance bar, the control electrode being grounded by a current source 5 The control voltage U_St between electrode 2 and control electrode 4 is activated. The control electrode 4 and the ground electrode 2 at least partially form a gap 3, the size of the gap can be changed according to the control voltage U_St applied between the control electrode 4 and the ground electrode 2, where the output pressure Pa is output as the air pressure at the outlet 46 The signal can be controlled depending on the control voltage U_St.

[0060] The ground elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com