Refrigerant content prediction method for a refrigeration system

A technology of refrigeration system and prediction method, applied in prediction, data processing application, calculation and other directions, can solve the problems of time-consuming and expensive fault diagnosis and maintenance, and achieve the effect of realizing refrigeration performance prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

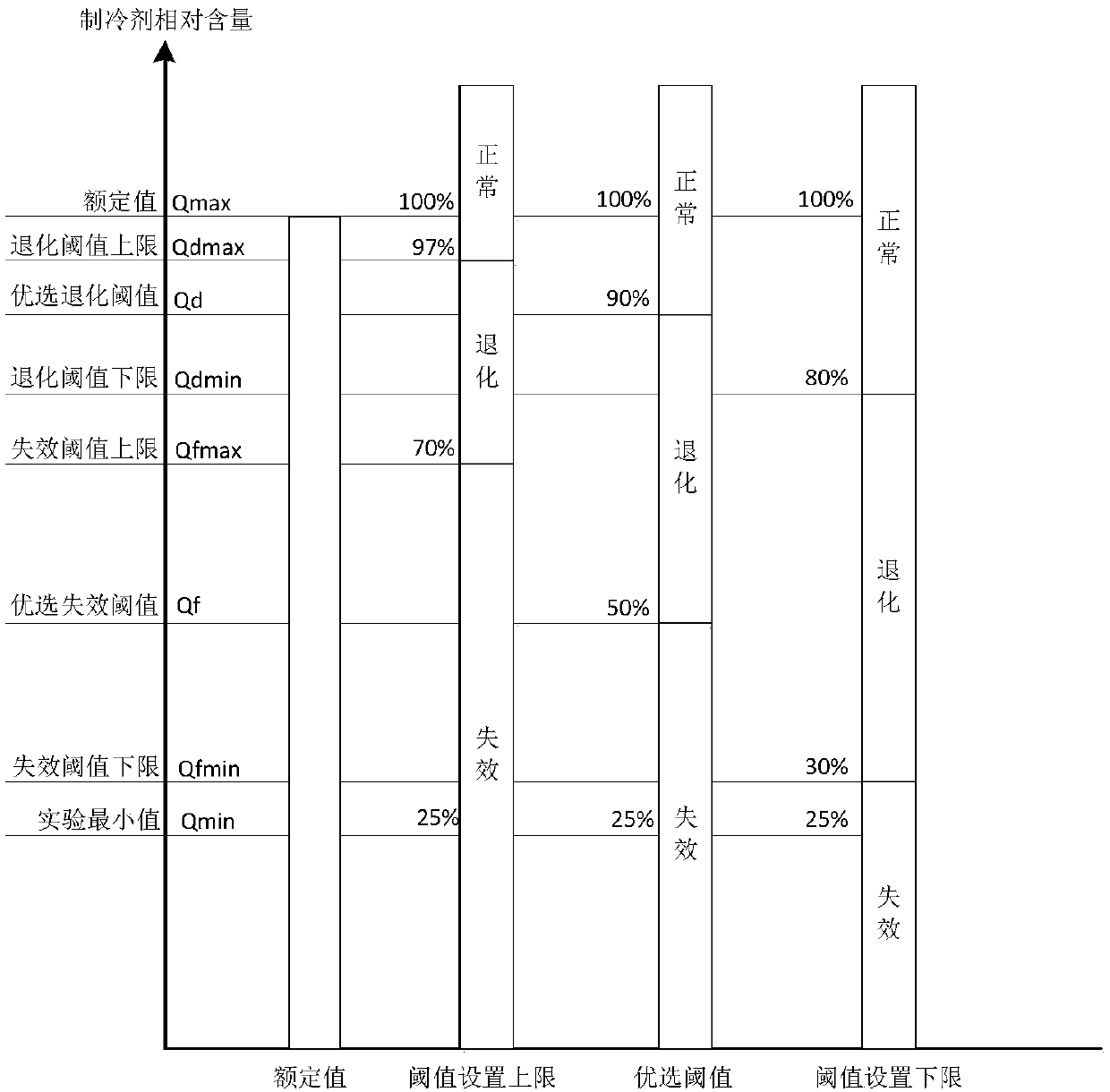

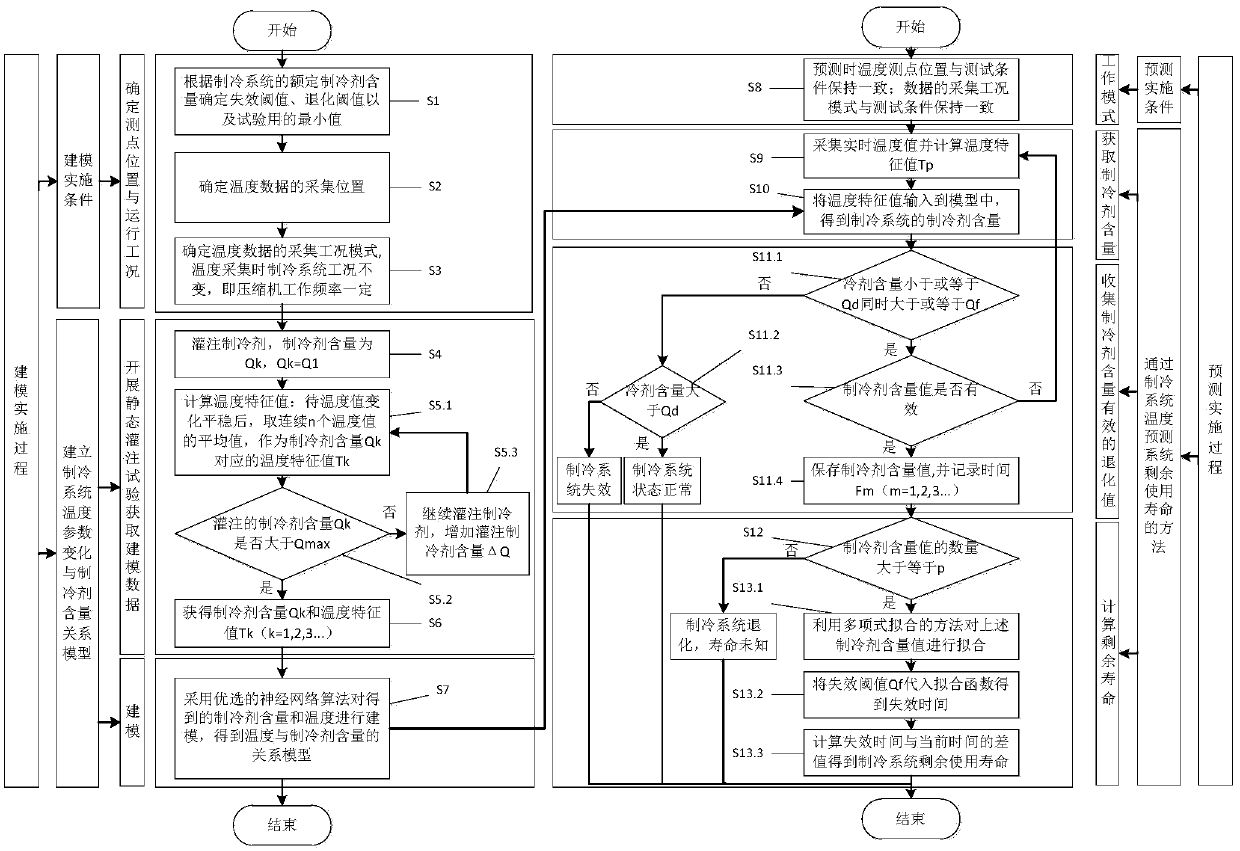

[0050] According to the refrigerant content prediction method used in refrigeration systems of the present invention, it is divided into a modeling implementation process and a prediction implementation process, which sets the implementation conditions, determines the location of the measuring point and the operating condition, and obtains the modeling data through the static perfusion test , by establishing the relationship model between the temperature parameter change and the refrigerant content of the refrigeration system, determining the forecast implementation conditions, selecting the working mode, and combining the above model with the method of predicting the remaining service life of the refrigeration system through the temperature of the refrigeration system, the refrigerant of the refrigeration system can be obtained content, collect the effective degradat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com