A device and method for measuring instantaneous fuel consumption of a diesel engine

A technology of measuring device and measuring method, which is applied in the direction of measuring device, relative volume flow measurement, liquid/fluid solid measurement, etc., and can solve the problem of inability to use artificial refueling liquid level dynamic balance method, large change of engine oil volume, oil pan liquid level, etc. problems such as large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

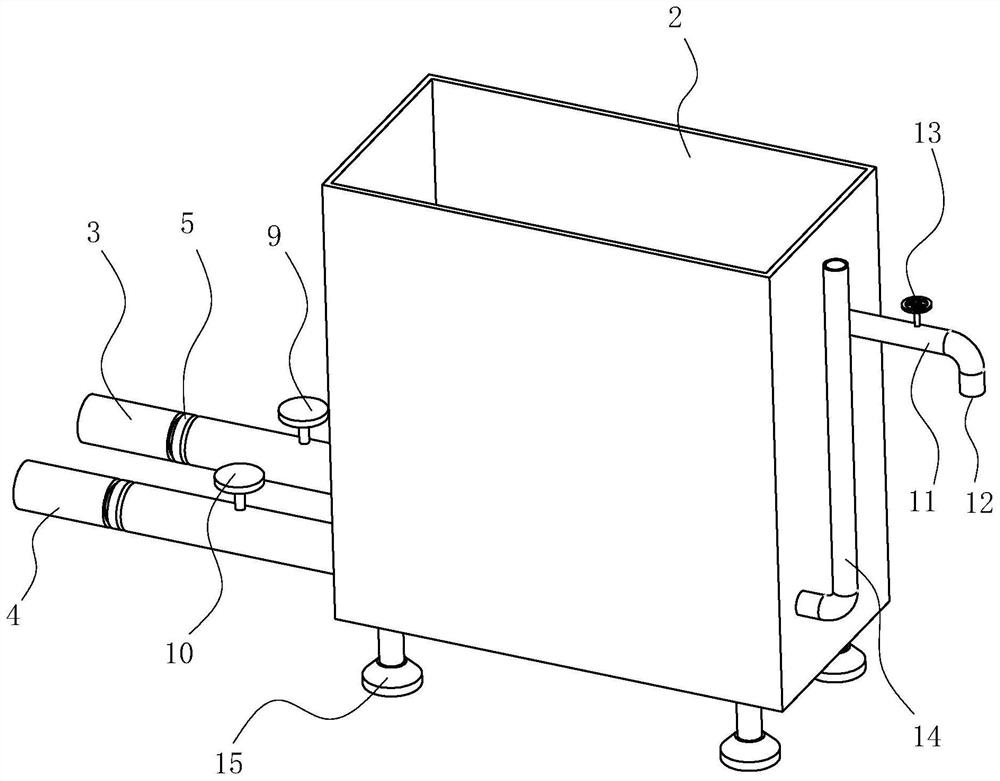

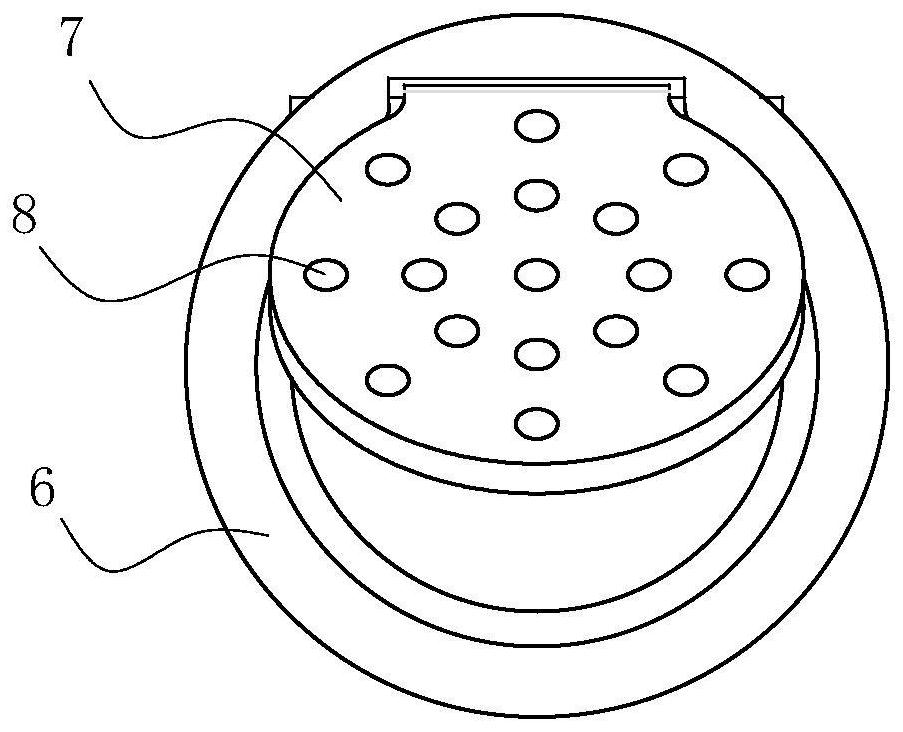

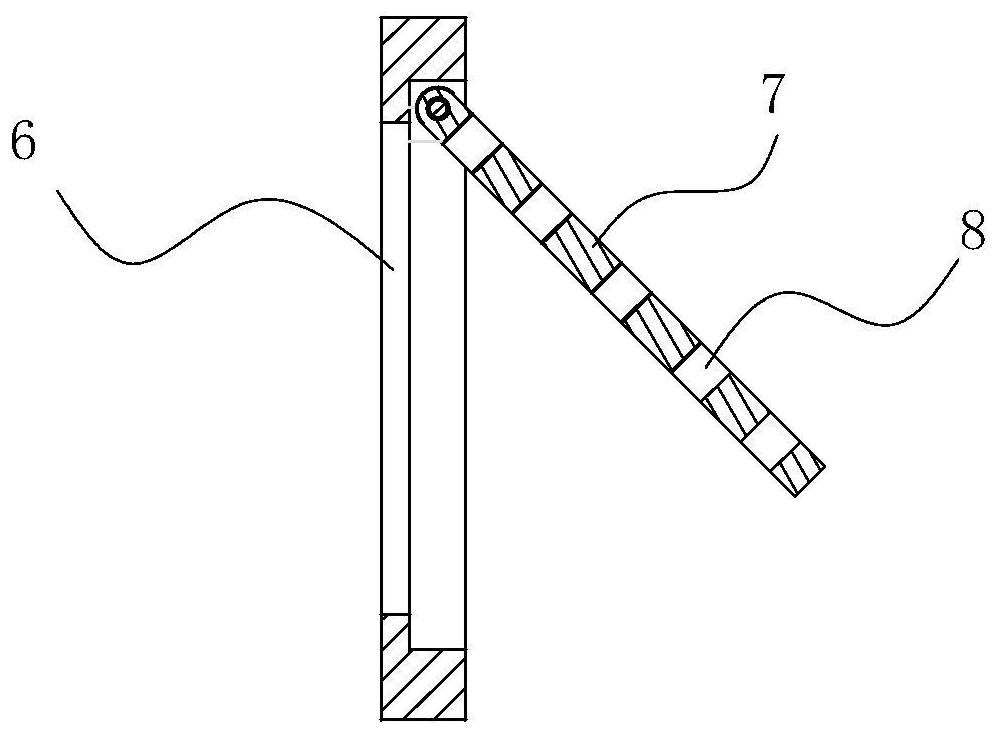

[0023] as Figure 1 、 Figure 2 、 Figure 3 and Figure 4 Commonly shown, a diesel engine instantaneous fuel consumption measurement device, comprising a pressure regulator box 2, the regulator box 2 through the inlet pipe 3 and the outlet pipe 4 and the oil pan 1 communication, the inlet pipe 3 and the outlet pipe 4 are installed on the check valve 5. Check valve 5 includes a valve body 6 and a valve plate 7 installed in the mounting groove on the side of the valve body, the upper end of the valve plate 7 is rotated with the valve body 6, when the oil flows from the side of the valve body 6 not connected to the valve plate 7 through the check valve 5, the valve plate 7 is opened. Valve plate 7 is opened with a small hole 8, two check valves 5 mounted in opposite directions. The pressure regulator 2 is provided with a drop line 11, the drop line 11 is provided with a drip shut-off valve 13, the drip port 11 of the drop tube 12 is provided below the oil connection tank 16. The oil pres...

Embodiment 2

[0027] as Figure 4 As shown, the measurement method of the diesel engine instantaneous fuel consumption measurement device, comprising the following steps:

[0028](1) After the oil temperature in the oil pan 1 of the diesel engine runs for a period of time reaches stability, open the oil inlet shut-off valve 9 on the inlet pipe 3 and the oil outlet shut-off valve 10 on the outlet pipe 4, by observing the oil pan 1 and the liquid level 14 on the regulator box 2, adjust the adjustment screw 15 on the regulator box 2 so that the oil level in the regulator box 2 is roughly the same as the oil level in the oil pan 1.

[0029] (2) When the oil level in the oil pan 1 is roughly the same as the height of the drop pipe 11, open the drip shut-off valve 13, and judge the liquid level by observing the oil drop 12 oil droplets. When the oil drip port 12 oil droplets at a rate of 30 to 35 drops per minute, the liquid level is considered to be balanced, close the drip shut-off valve 13, empty t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com