A comprehensive stiffness measuring device for servo valve armature assembly

A measuring device and servo valve technology, which is applied in the field of hydraulic devices, can solve the problems of not being able to respond to the stress and deformation of the armature components, and achieve the effect of accurate positioning and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A comprehensive stiffness measurement device for a servo valve armature assembly provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

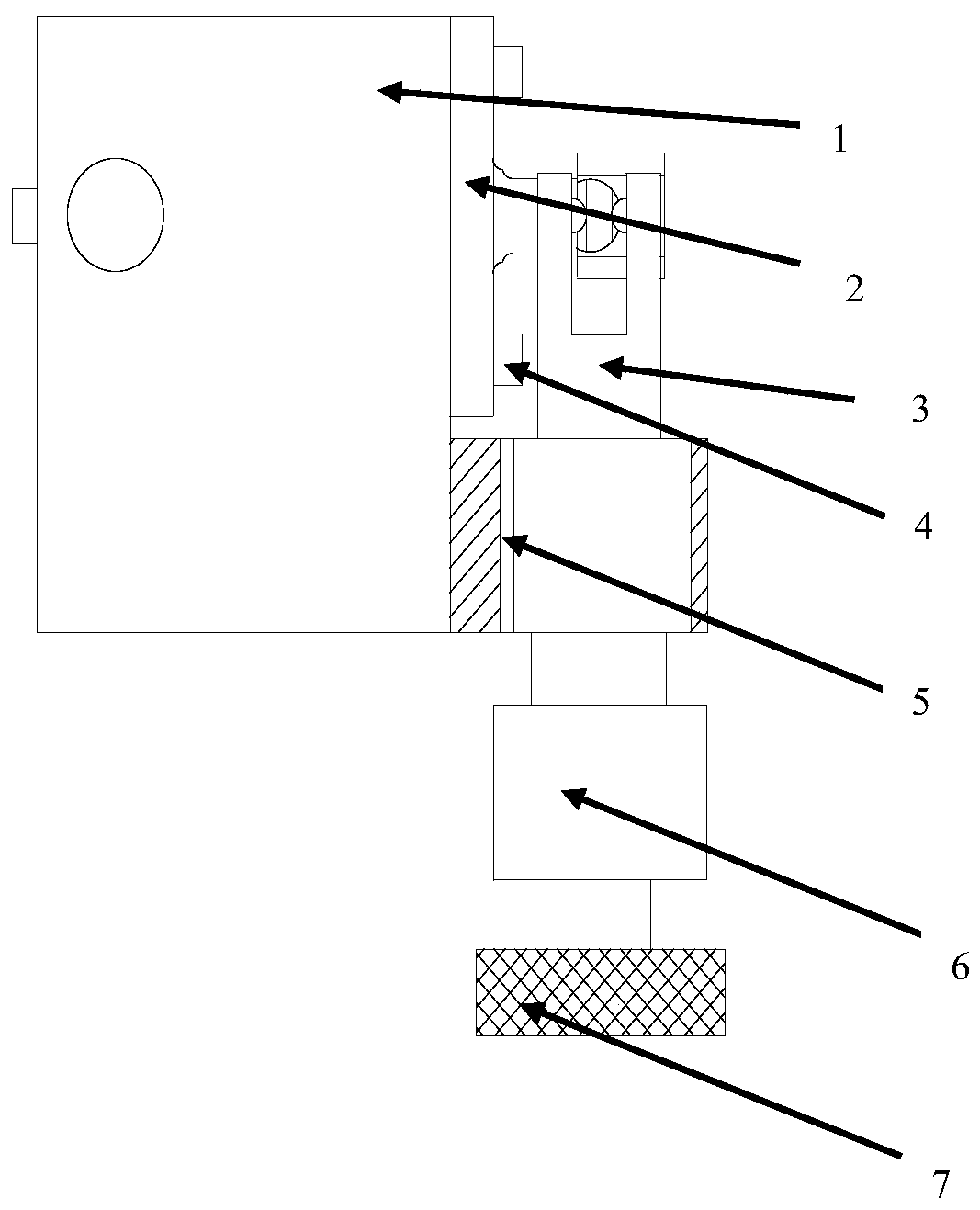

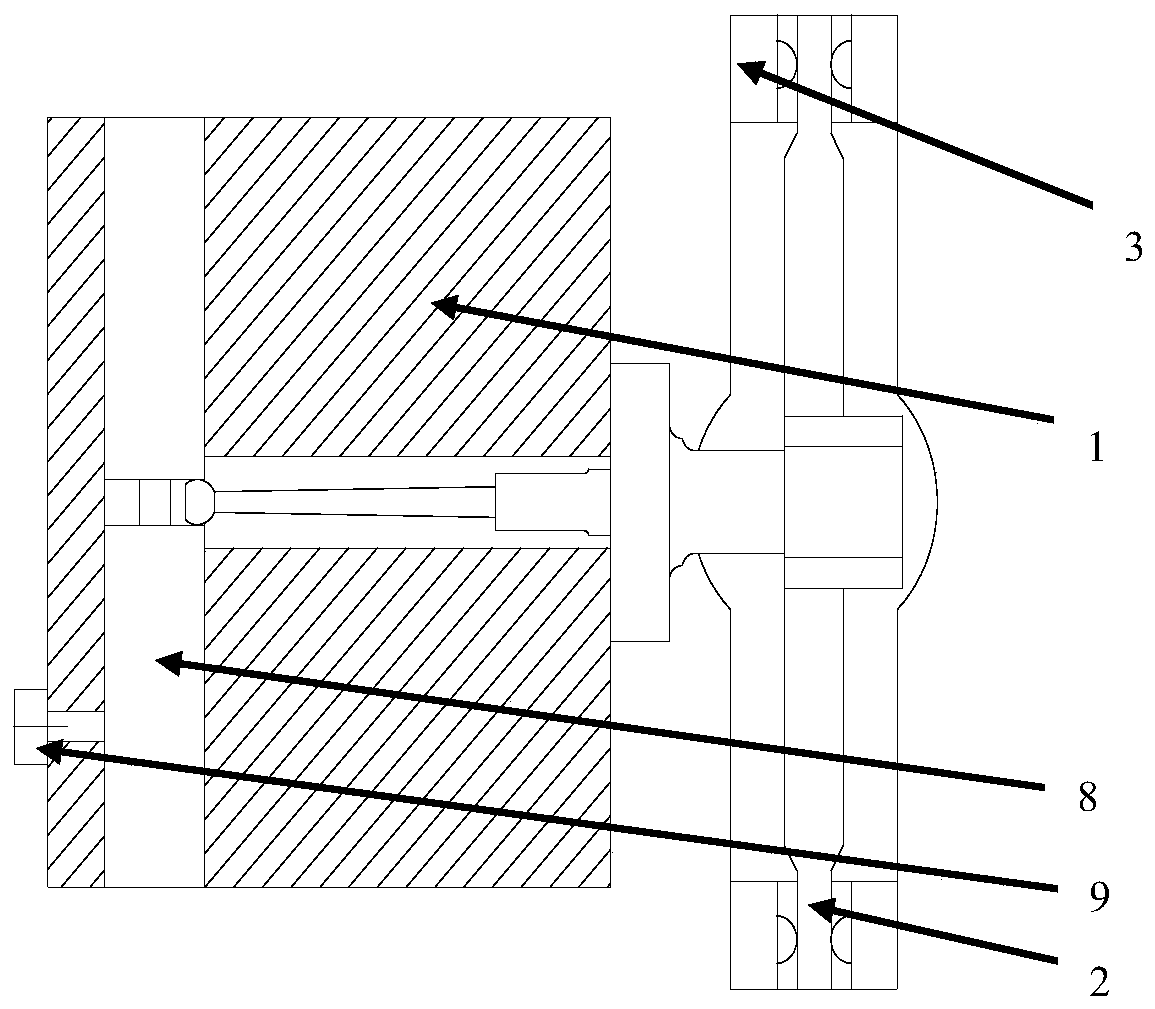

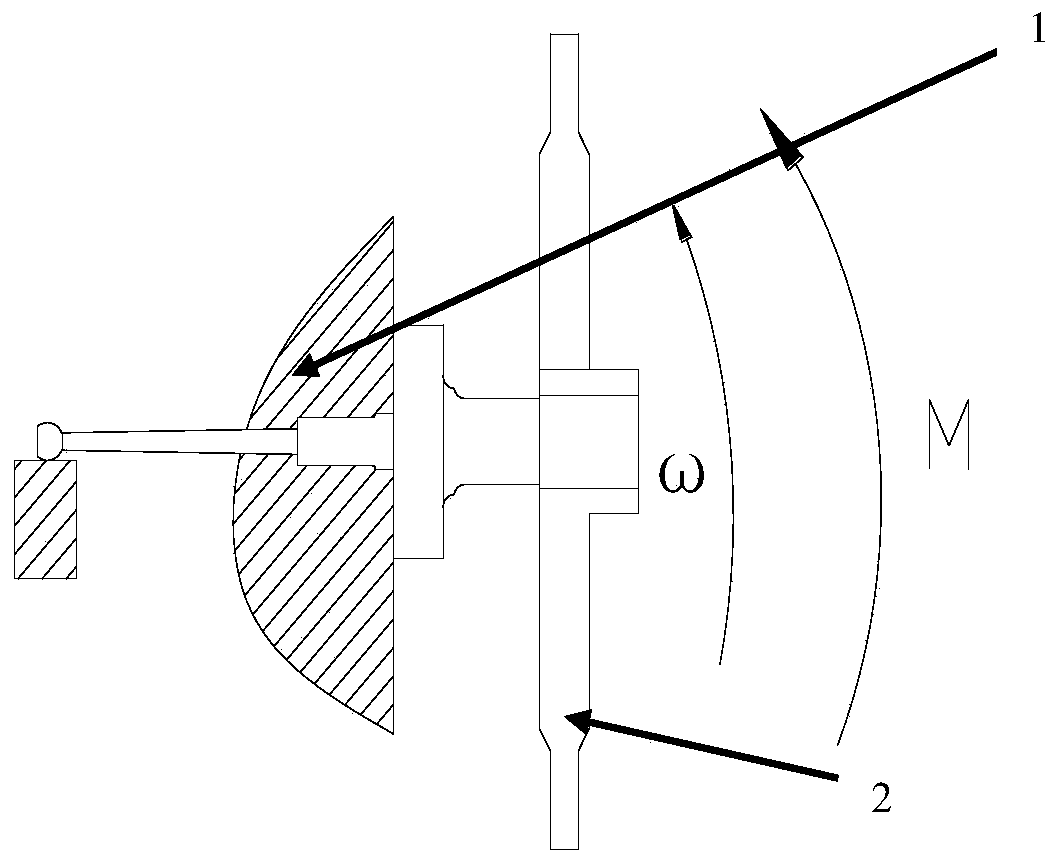

[0017] Such as figure 1 and figure 2 As shown, a comprehensive stiffness measurement device for a servo valve armature assembly provided by the present invention includes a mounting base 1, an armature assembly 2, a rotating fork 3, a fixing screw 4, an angle sensor 5, a torque sensor 6, a micro-drive wheel 7, Locking spool 8, locking screw 9; there is a through hole on the installation base 1, the locking spool 8 is inserted into the through hole and fits with the installation base 1, and can slide flexibly. A locking screw 9 is installed on the surface, and the locking screw 9 is threadedly connected with the installation base 1 and withstands the locking valve core 8; the armature assembly 2 is fixedly installed on the installation base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com