Production process for CPU and popcorn compound transparent soles

A production process and popcorn technology, applied in the field of shoe soles, can solve the problems of weak graininess of etpu and heavy product weight, and achieve the effect of improving the sense of technology, cleaning convenience, and satisfying the pursuit of psychology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

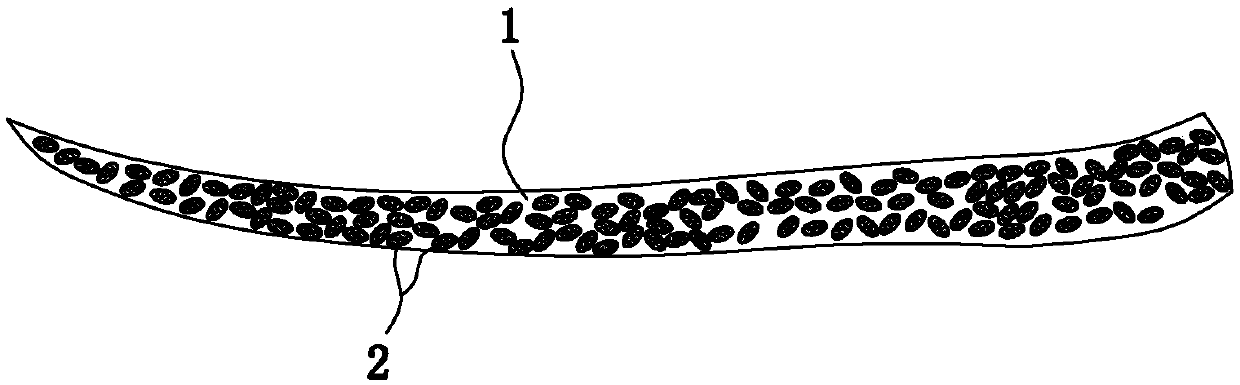

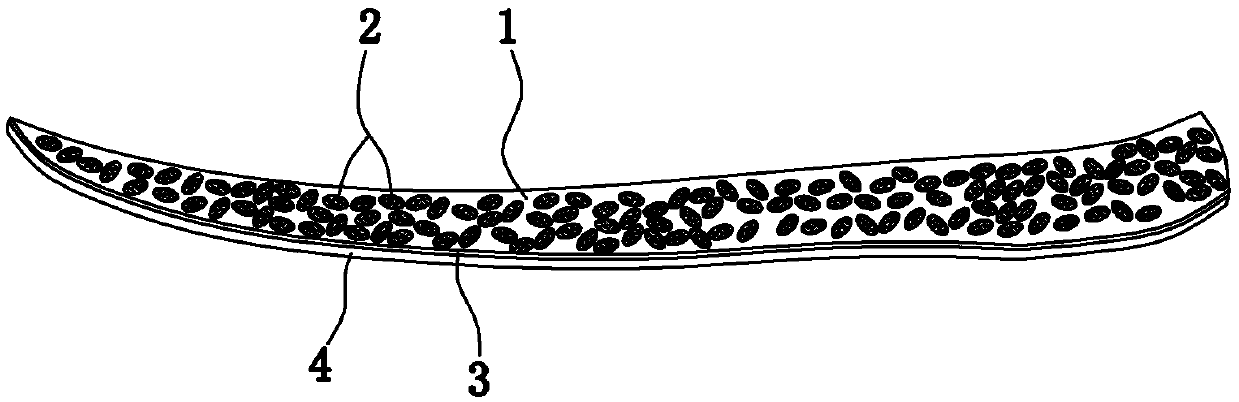

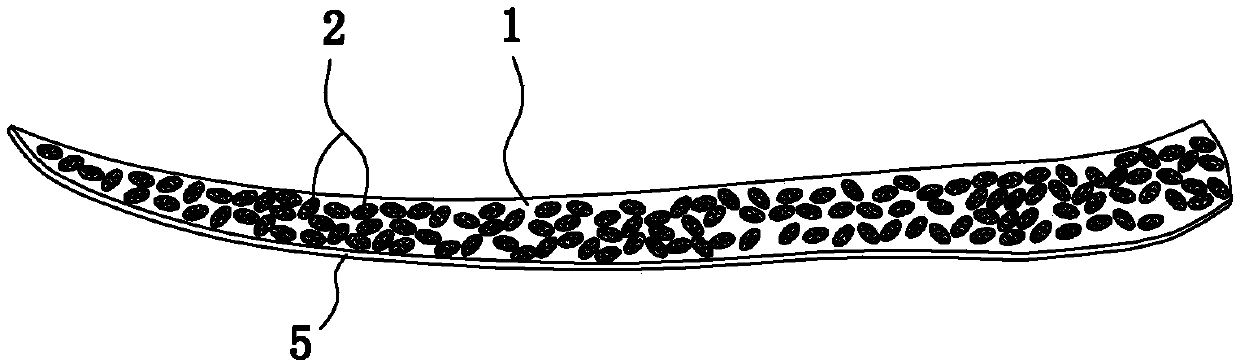

[0027] like figure 1 As shown, it is the structural representation of the first embodiment of the sole produced by the production process involved in the present invention, which includes a transparent CPU material 1 and some etpu particles 2 embedded in the CPU material 1, each etpu particle 2 is surrounded by Filled with CPU material 1.

[0028] please cooperate figure 1 and Figure 4 Shown, the present invention relates to a kind of production technology of CPU and popcorn compound transparent sole, comprises the steps:

[0029] 1. etpu granules 2 are placed in the forming mold, the forming mold has an upper mold 61, a lower mold 62 and a cavity 63 between the upper mold 61 and the lower mold 62, and the etpu granules 2 are filled to 1 / 2 -3 / 4 cavity 63 area;

[0030] 2. Pouring the CPU liquid in the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com