Mismatched type flexible anti-stabbing material and preparation method thereof

A flexible, composite material technology, used in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of bloated clothing, hidden dangers, heavy weight, etc., to improve softness and breathability, improve wearing flexibility, and reduce gap length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

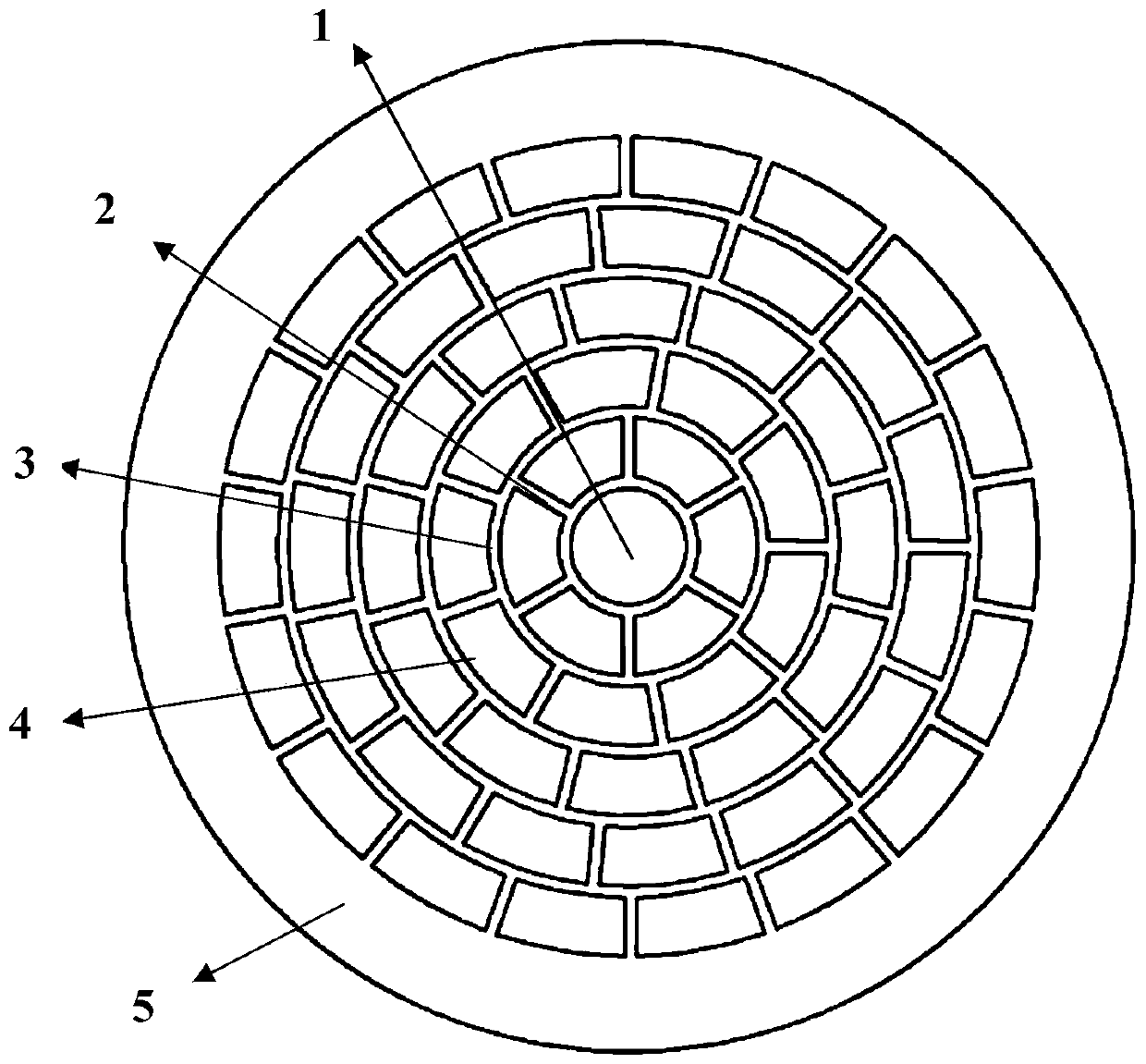

[0036] Such as figure 1 As shown, this embodiment provides a dislocation flexible stab-proof material, including a flexible base cloth 5 and a first protective module 1 in the middle fixed on one side of the flexible base cloth 5 and multiple types of second protective modules located on the outside. 4. The first protection module 1 is cylindrical, and the second protection module 4 is arranged in a multi-layer circular ring structure around the first protection module 1. The first protection module 1 and the second protection module 4 constitute a whole protection unit.

[0037] The multi-layer ring-shaped structure is arranged sequentially from the inside to the outside. The ring-shaped structure of the same layer is formed by splicing a plurality of second protection modules 4 with gaps between each other, and the second protection modules 4 of different layers are staggered. The gap 3 between the annular structures of each layer decreases gradually from the inside to the o...

Embodiment 2

[0048] Such as figure 1As shown, this embodiment provides a dislocation flexible stab-proof material, including a flexible base cloth 5 and a first protective module 1 in the middle fixed on one side of the flexible base cloth 5 and multiple types of second protective modules located on the outside. 4. The first protection module 1 is cylindrical, and the second protection module 4 is arranged in a multi-layer circular ring structure around the first protection module 1. The first protection module 1 and the second protection module 4 constitute a whole protection unit.

[0049] The multi-layer ring-shaped structure is arranged sequentially from the inside to the outside. The ring-shaped structure of the same layer is formed by splicing a plurality of second protection modules 4 with gaps between each other, and the second protection modules 4 of different layers are staggered. The gap 3 between the annular structures of each layer decreases gradually from the inside to the ou...

Embodiment 3

[0060] Such as figure 1 As shown, this embodiment provides a dislocation flexible stab-proof material, including a flexible base cloth 5 and a first protective module 1 in the middle fixed on one side of the flexible base cloth 5 and multiple types of second protective modules located on the outside. 4. The first protection module 1 is cylindrical, and the second protection module 4 is arranged in a multi-layer circular ring structure around the first protection module 1. The first protection module 1 and the second protection module 4 constitute a whole protection unit.

[0061] The multi-layer ring-shaped structure is arranged sequentially from the inside to the outside. The ring-shaped structure of the same layer is formed by splicing a plurality of second protection modules 4 with gaps between each other, and the second protection modules 4 of different layers are staggered. The gap 3 between the annular structures of each layer decreases gradually from the inside to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com