Pressure plate locking device

A locking device and pressing plate technology, applied in the field of locks, can solve problems such as misoperation of power wiring devices, and achieve the effect of avoiding electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

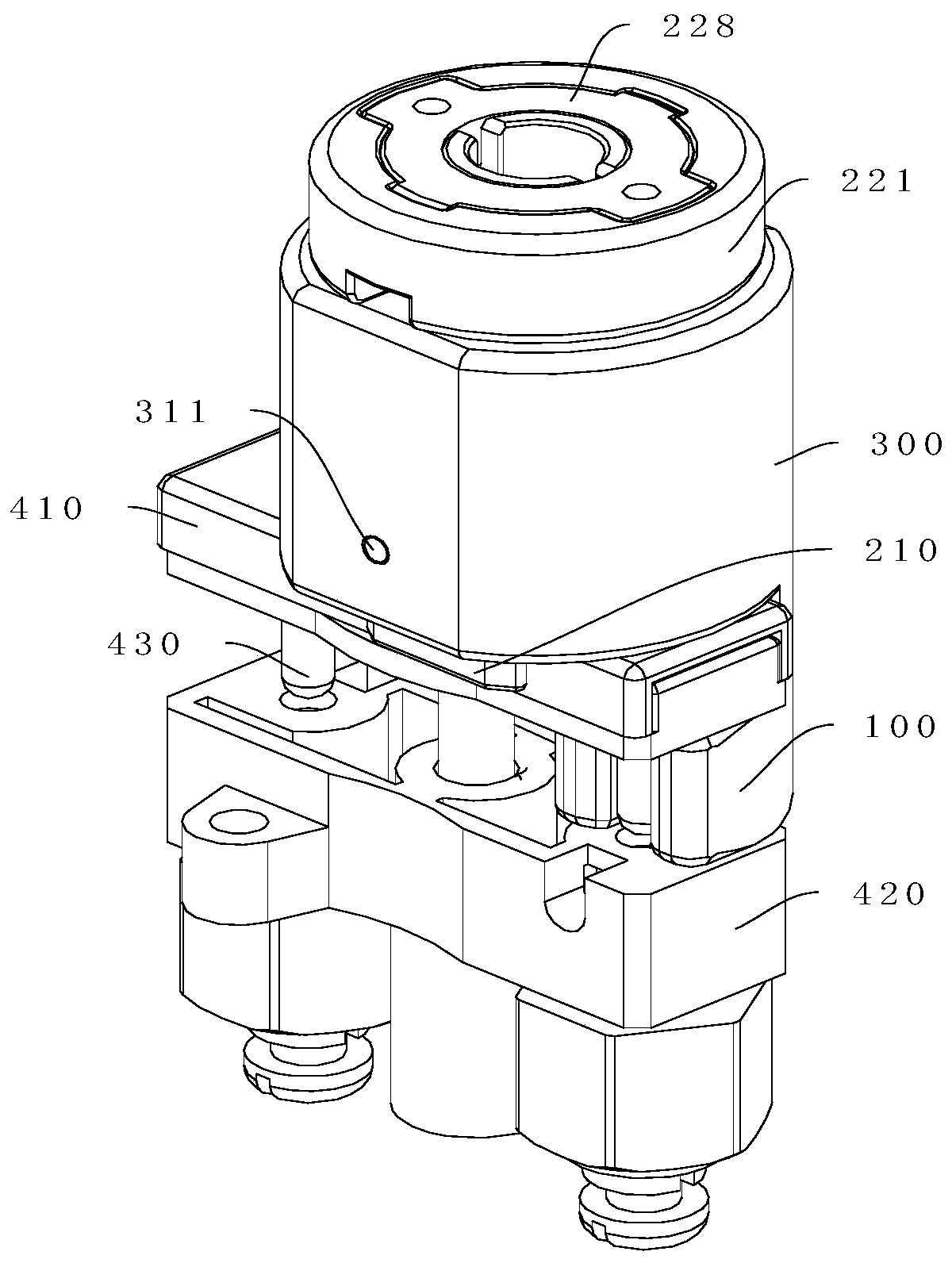

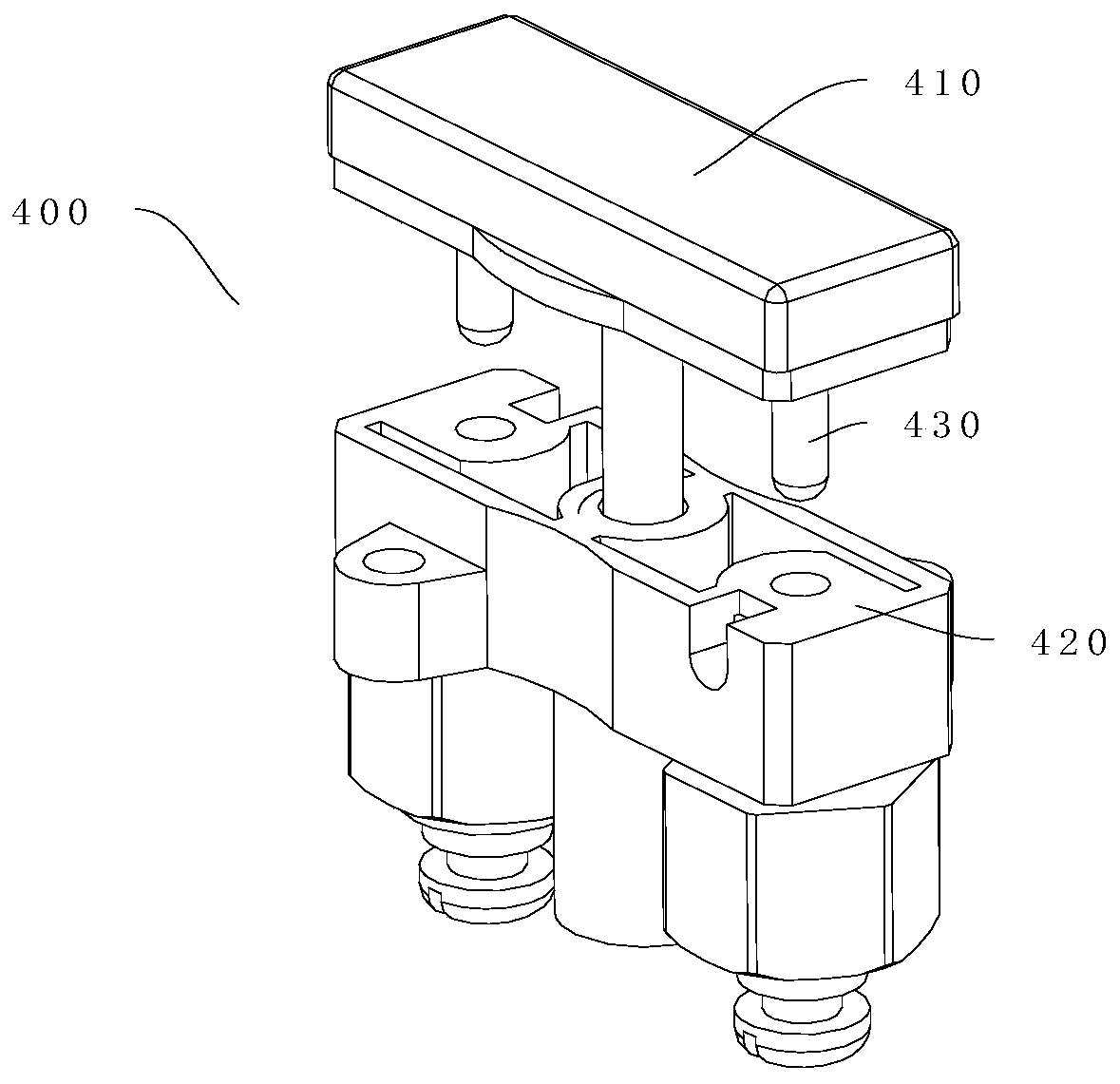

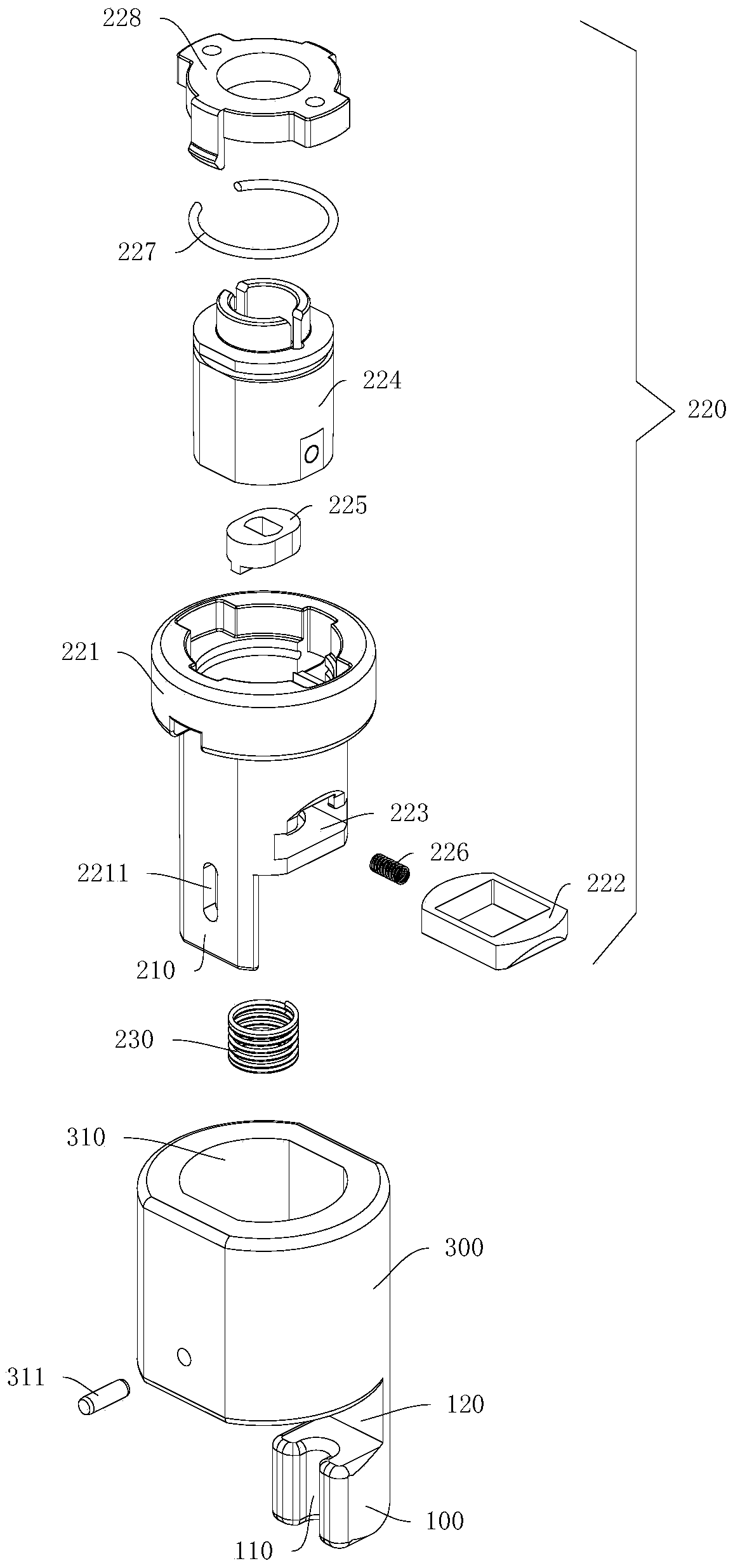

[0053] Such as figure 1 , figure 2 As shown, the pressure plate locking device includes a housing 300, a protruding structure 210, and a lock body assembly 220 for locking the protruding structure 210. A part of the housing 300 serves as the positioning and holding portion 100 and has a handle container for accommodating a pressure plate handle 410. When the pressure plate handle 410 is in the handle accommodating cavity 120, the positioning and holding portion 100 is located between the pressure plate handle 410 and the pressure plate base 420, so that the plug 430 of the pressure plate handle 410 and the conductive socket 421 of the pressure plate base 420 are held Separate state; the extended structure 210 has an extended position and a retracted position relative to the housing 300, and when the pressing plate handle 410 is in the handle accommodating cavity 120, the pressing plate handle 410 can be locked with the positioning and holding portion 100; the lock body assembly ...

Embodiment 2

[0076] The difference from the first embodiment is that the structure of the pressure plate locking device is different from that in the first embodiment, but the locking principle is similar.

[0077] Specific, such as Figure 11 to Figure 20 As shown, the extension structure 210 is a locking plate, and the first end of the locking plate extends into the housing 300 through the relief opening 312 of the housing 300, and the second end of the locking plate is always located outside and opposite to the housing 300. The position of the positioning and holding portion 100 can be changed. When the lock body assembly 220 is in the locked state, the first end of the extension structure 210 is locked with the housing 300, and the second end of the extension structure 210 is crimped on the positioning and holding portion 100 and The pressing plate handle 410 is used to prevent the pressing plate handle 410 from slipping out of the handle containing cavity 120.

[0078] When the plate need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com