Secondary pressing plate forced locking device and method for forced locking thereof

A secondary pressure plate and locking device technology, applied in substation/switch layout details, electrical components, etc., can solve problems such as cumbersome installation, No. The effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

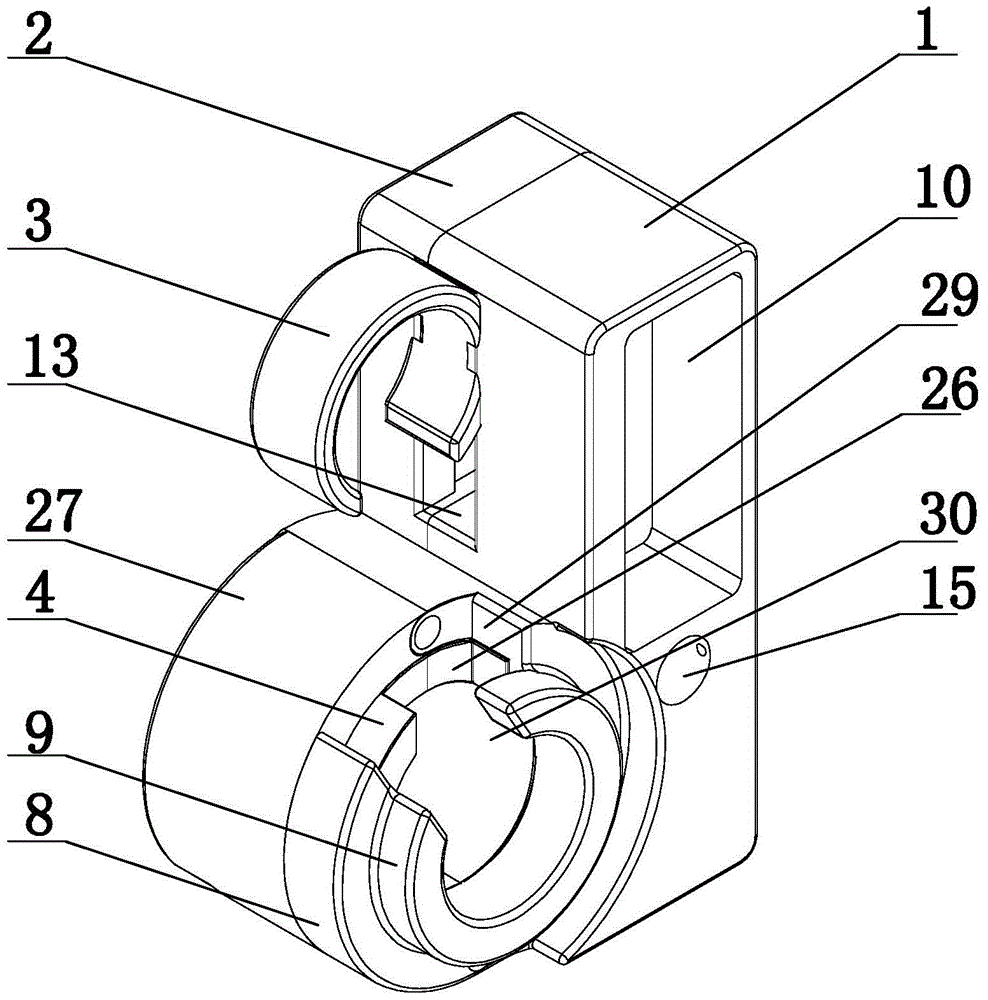

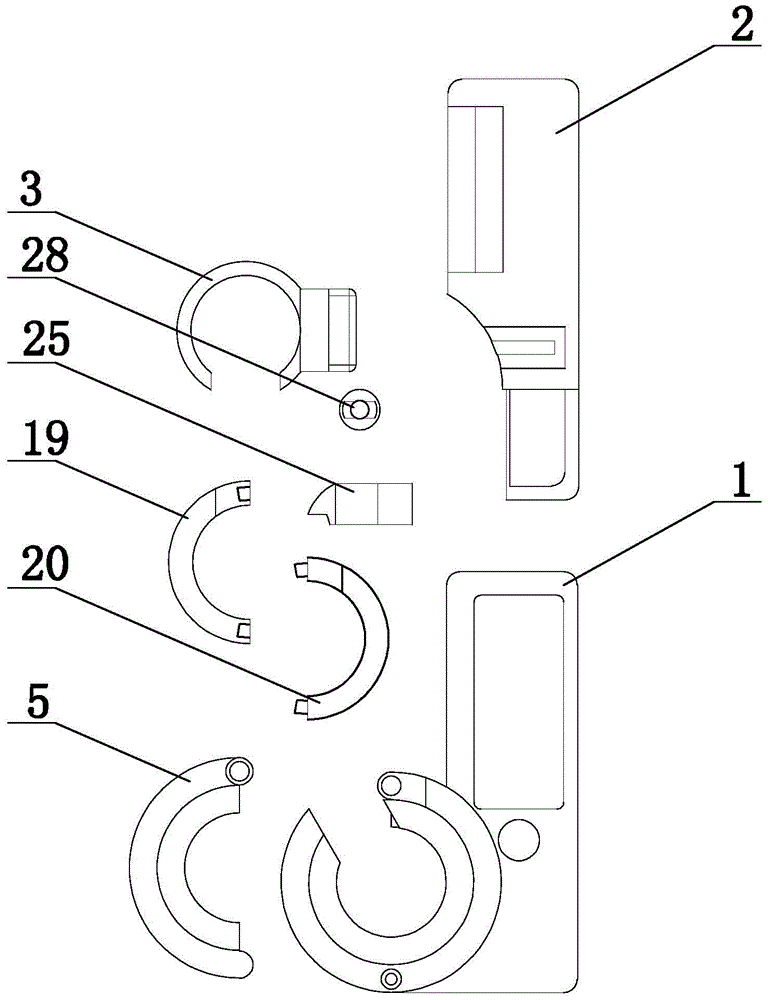

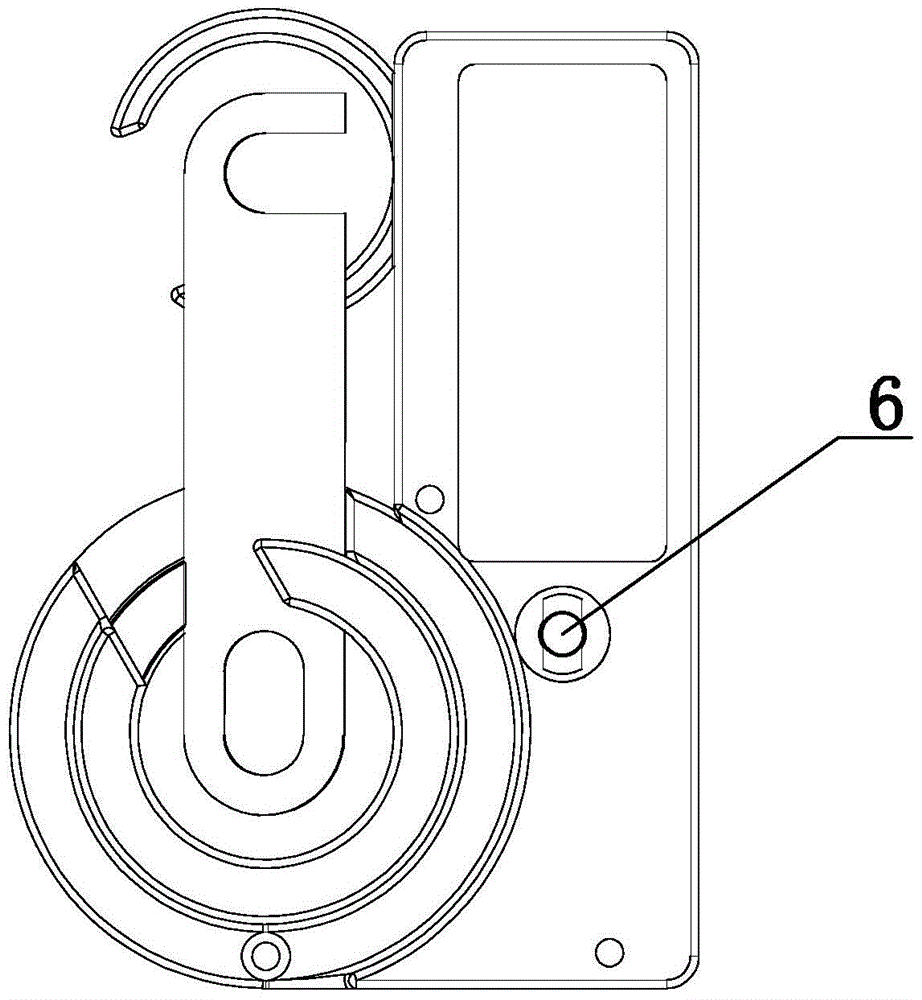

Embodiment 1

[0051] Embodiment 1: The secondary pressure plate forced locking device according to the present invention includes a casing, and also includes the following components: upper casing 1, lower casing 2, static contact ferrule 3, internal rotating shaft 4 of ferrule, and locking sleeve The left half of the base 5, the internal lock 6 and the RFID chip 7, the upper shell 1 is provided with the moving contact lock sleeve 8, the rotation track groove guard plate 9, the RFID chip installation groove 10 and the groove 11, the rotation track groove Guard plate 9 is located in moving contact lock sleeve 8, and is fixedly connected, and RFID code chip installation groove 10 side is provided with keyhole 15; Both lower shell 2 and upper shell 1 are provided with screw holes, and are connected by bolts. The upper shell 1 and the lower shell 2 are fixedly connected in the screw hole, and the lower shell 2 is provided with a groove B12 corresponding to the groove 11 of the upper shell 1, and...

Embodiment 2

[0052] Embodiment 2: On the basis of the structure described in Embodiment 1, the static contact ferrule moving groove 13 includes a slider sliding track and a connecting block sliding track, the section of the slider sliding track is adapted to the slider section, and the connecting block sliding track The cross-section is less than the cross-section of the slide block, so that the slide block 18 can only move in the slide block sliding track, but cannot pass the connecting block sliding track.

Embodiment 3

[0053] Embodiment 3: On the basis of the structure described in Embodiment 2, the locking sleeve clamping base 27 is set on the moving contact base of the pressure plate, the moving contact lock sleeve 8 is set on the moving contact of the pressure plate, and the pressure plate connecting piece Pass through the slot 26 of the connecting piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com