Patents

Literature

39results about How to "Play a stop role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

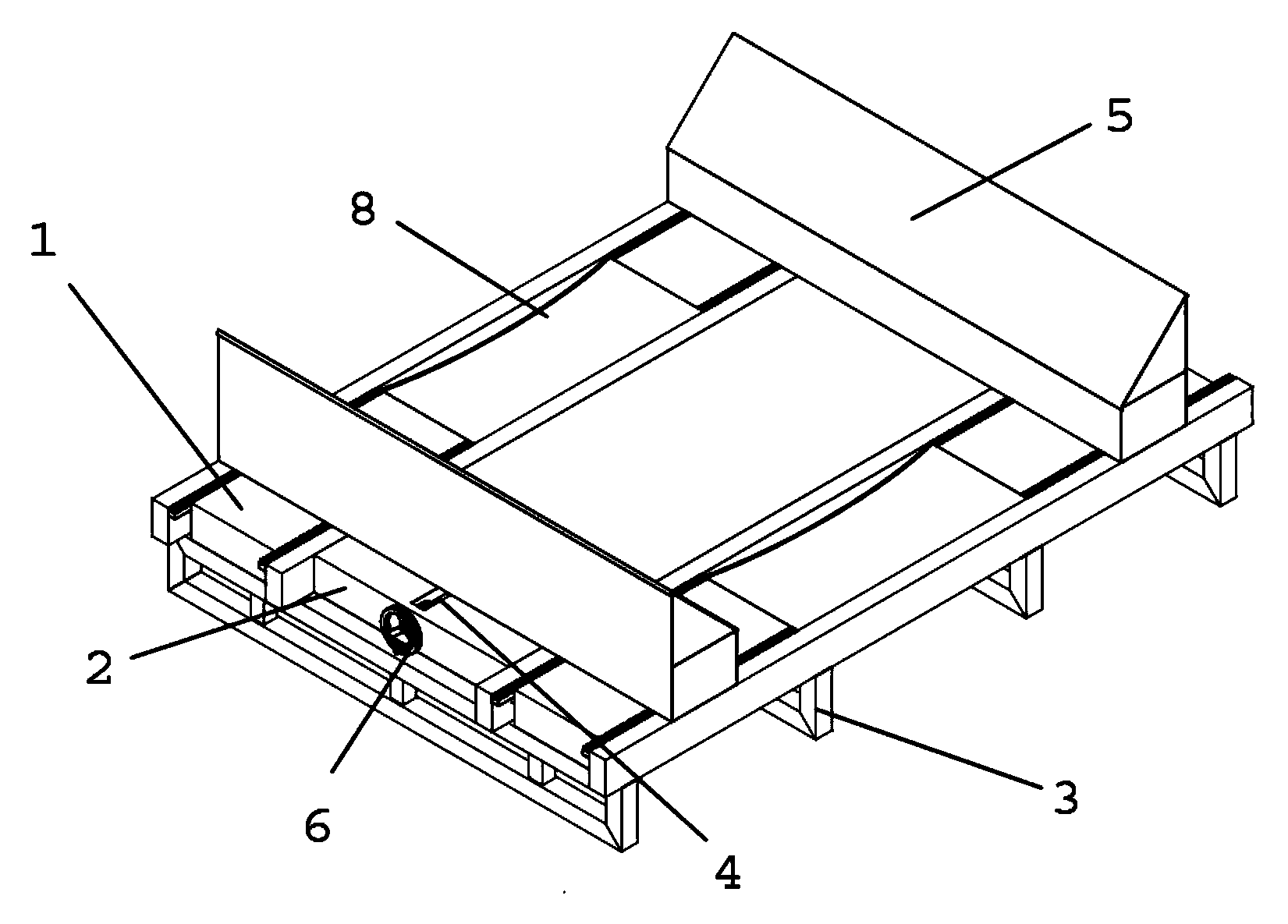

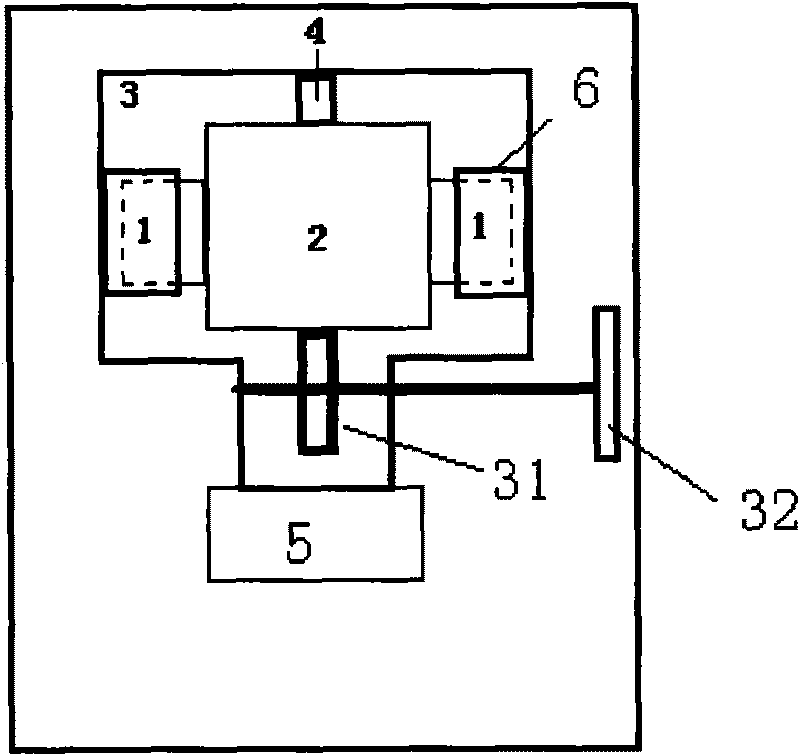

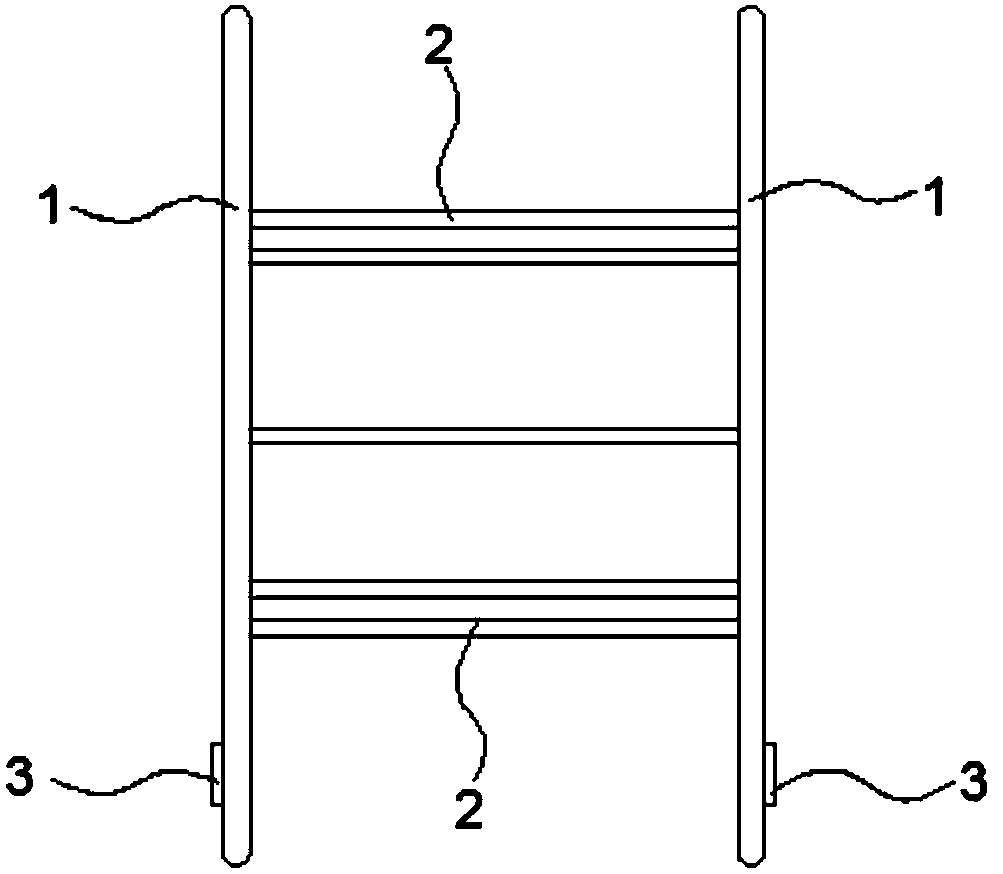

Adjustable dual-purpose bearing tray

The invention discloses an adjustable dual-purpose bearing tray, which comprises two strip-shaped bearing plates (1), a connecting plate (2) and framework-shaped support frames (3), wherein the two strip-shaped bearing plates (1) are transversely arranged in parallel and are used for bearing cargoes; the connecting plate (2) is arranged between the two bearing plates (1); the framework-shaped support frames (3) which are arranged below the bearing plates (1) , vertically arranged in parallel and in contact with the ground. The adjustable dual-purpose bearing tray is characterized in that a movable screw (4) is transversely arranged in the connecting plate (2); two movable backstop strips (5) are respectively and vertically arranged at upper sides of both ends of one of the two bearing plates (1) and upper sides of both ends of the other bearing plate (1); a protruding screw hole is formed in the lower part of each backstop strip (5) and is in screw joint with the movable screw (4) through an open slot in the connecting plate (2), and can rotate with the movable screw (4) to move along the movable screw (4). According to the adjustable dual-purpose bearing tray disclosed by the invention, the warehouse space can be saved, the warehousing time is shortened; management is convenient; the cost is reduced; the production efficiency is improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

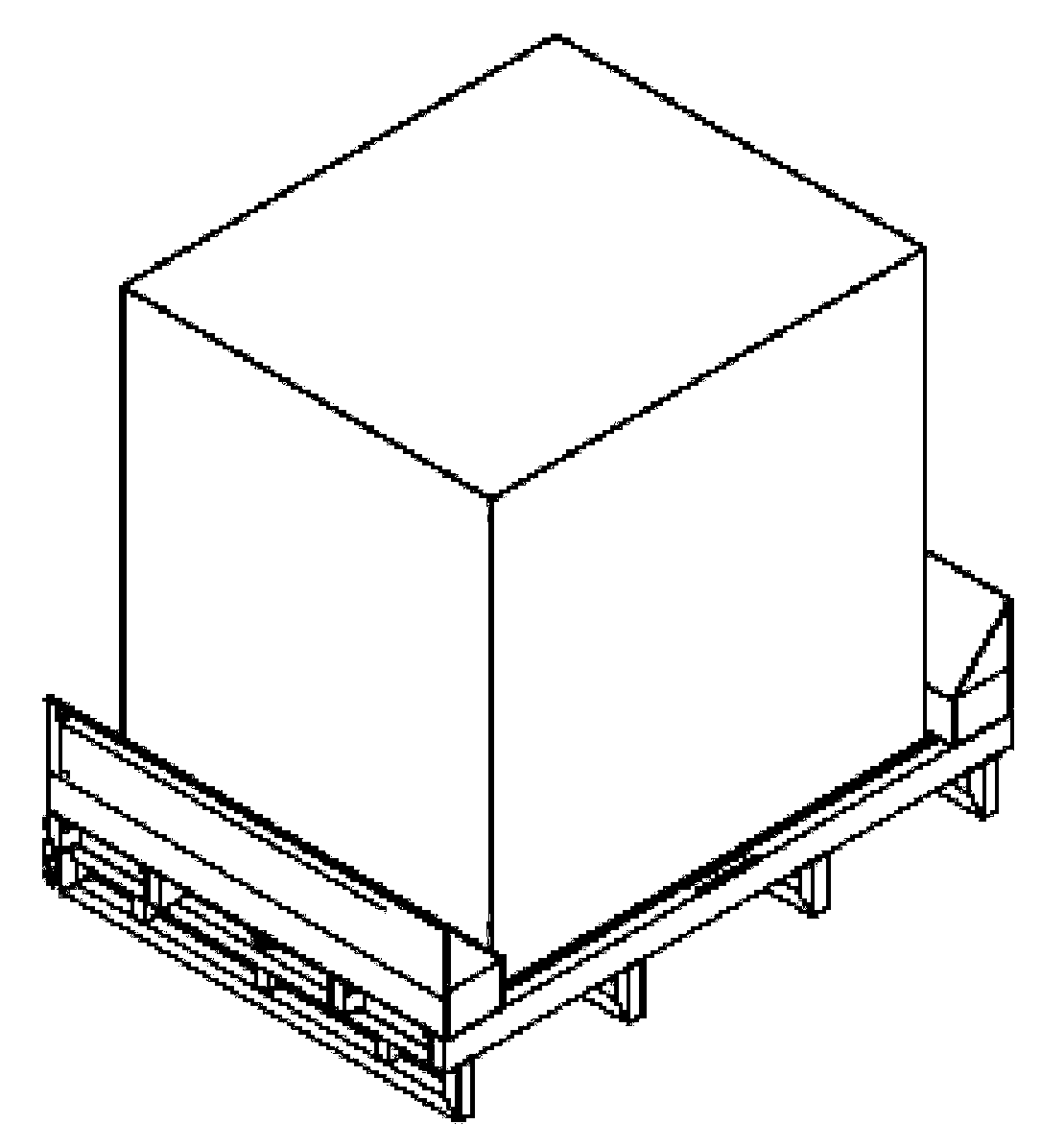

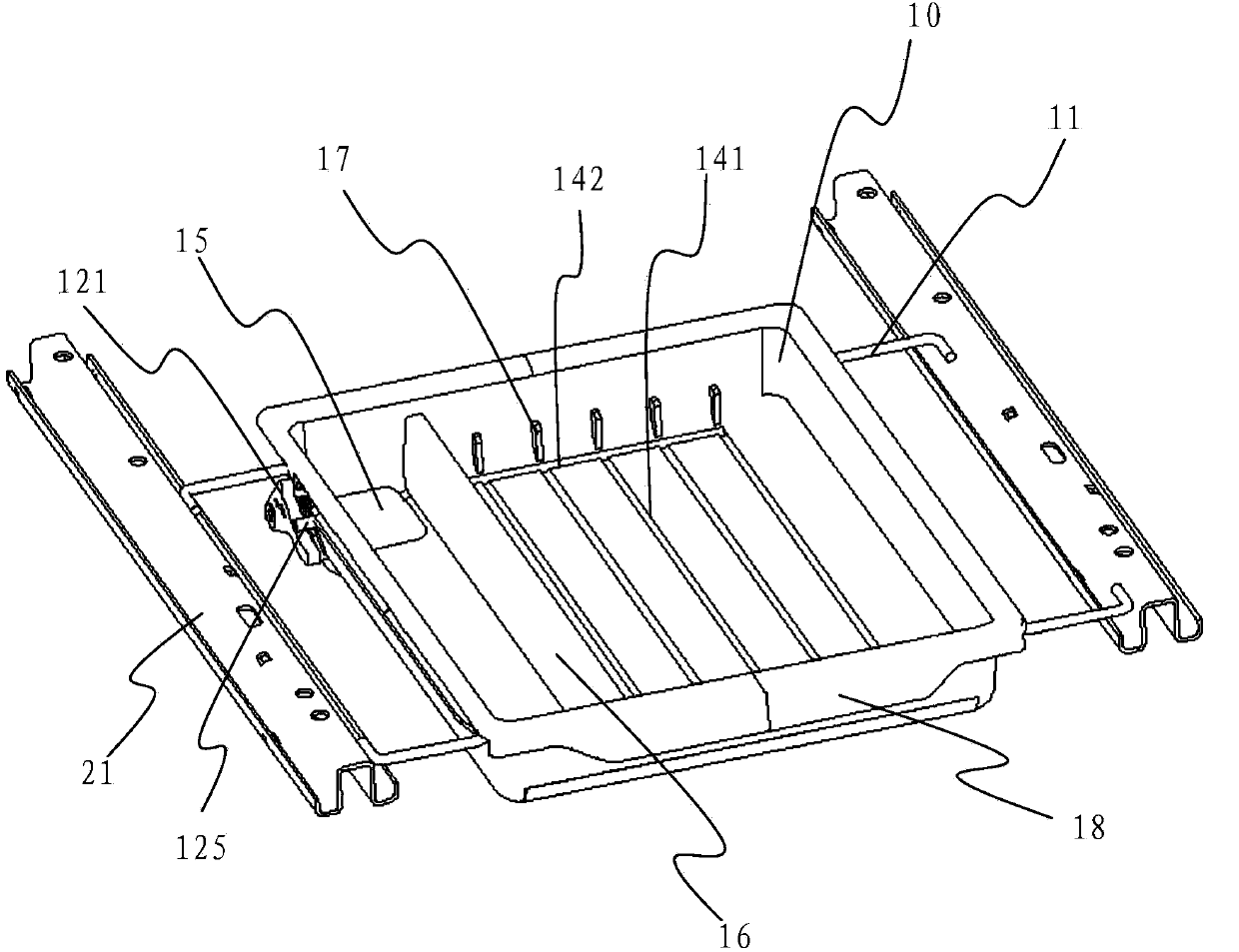

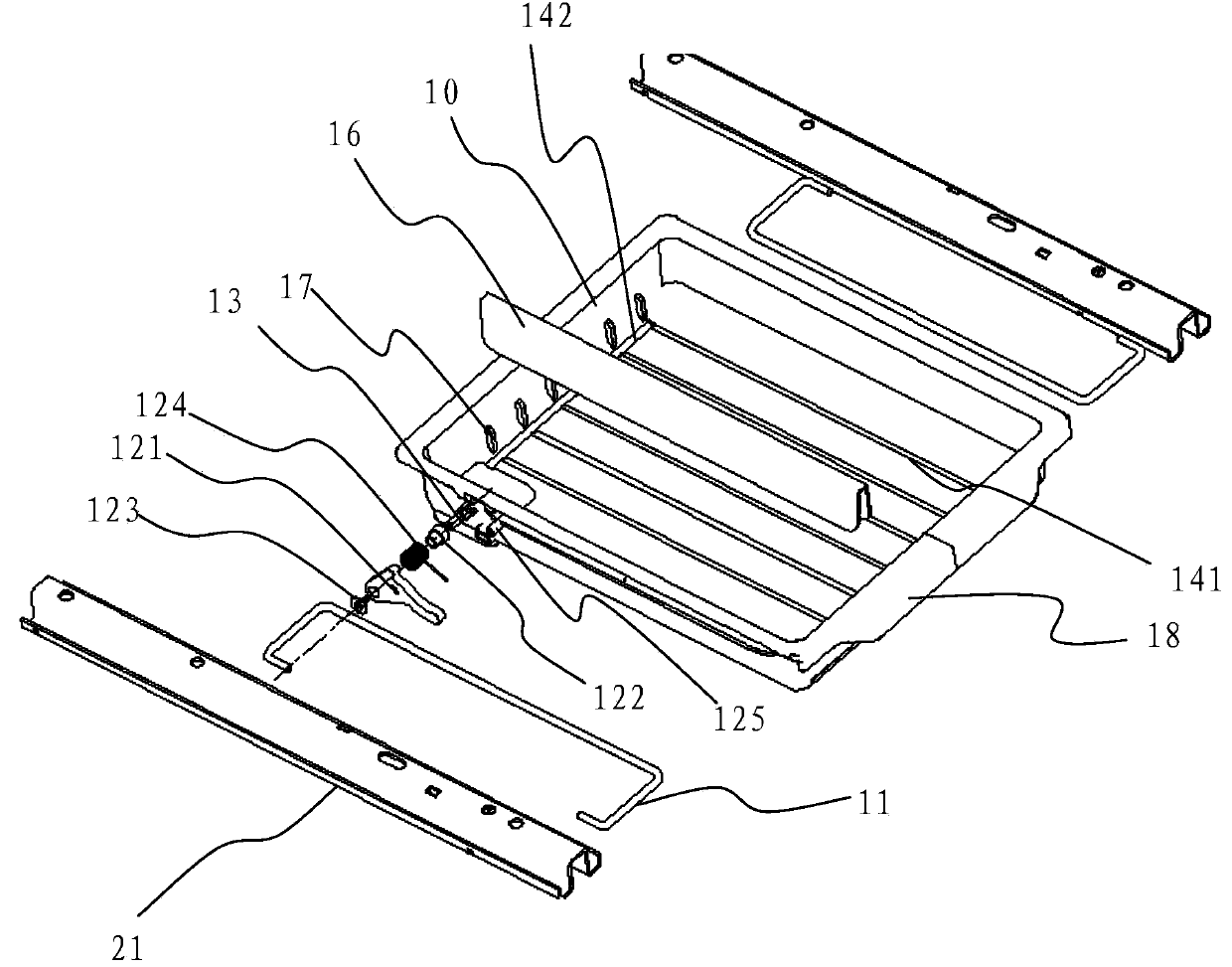

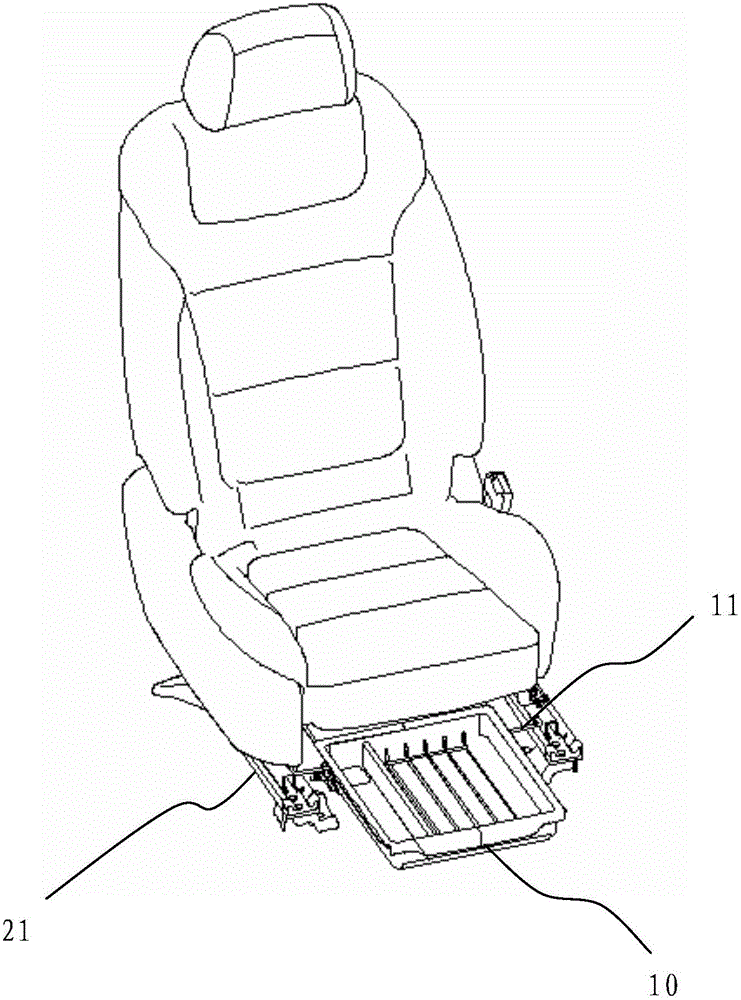

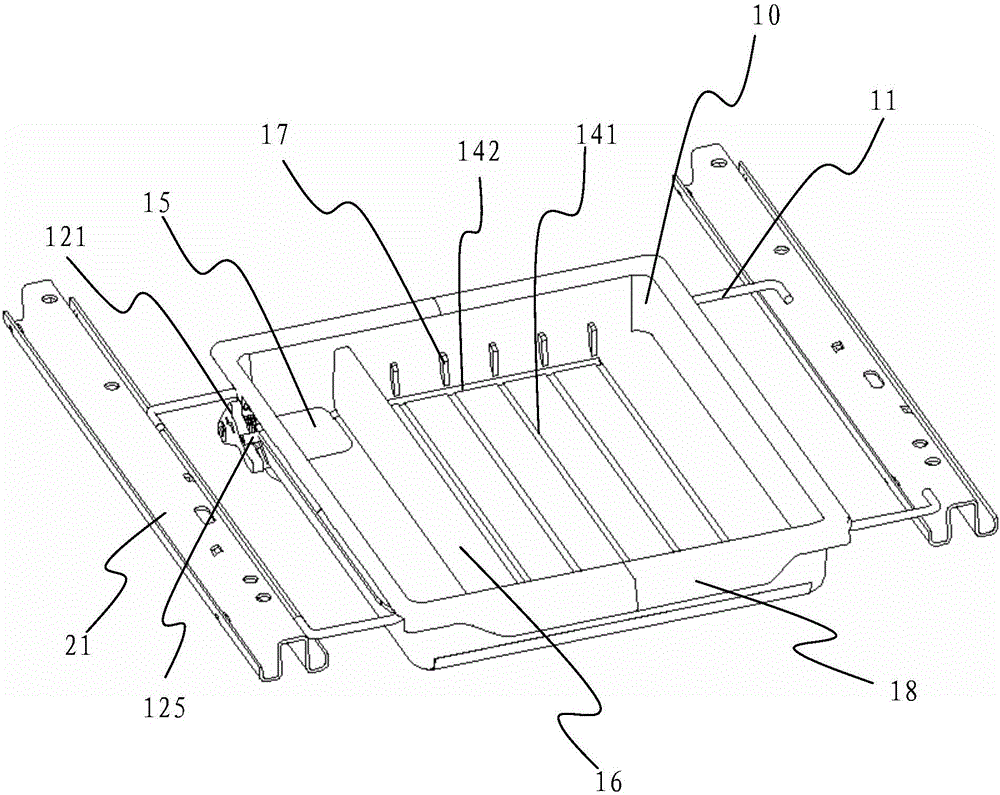

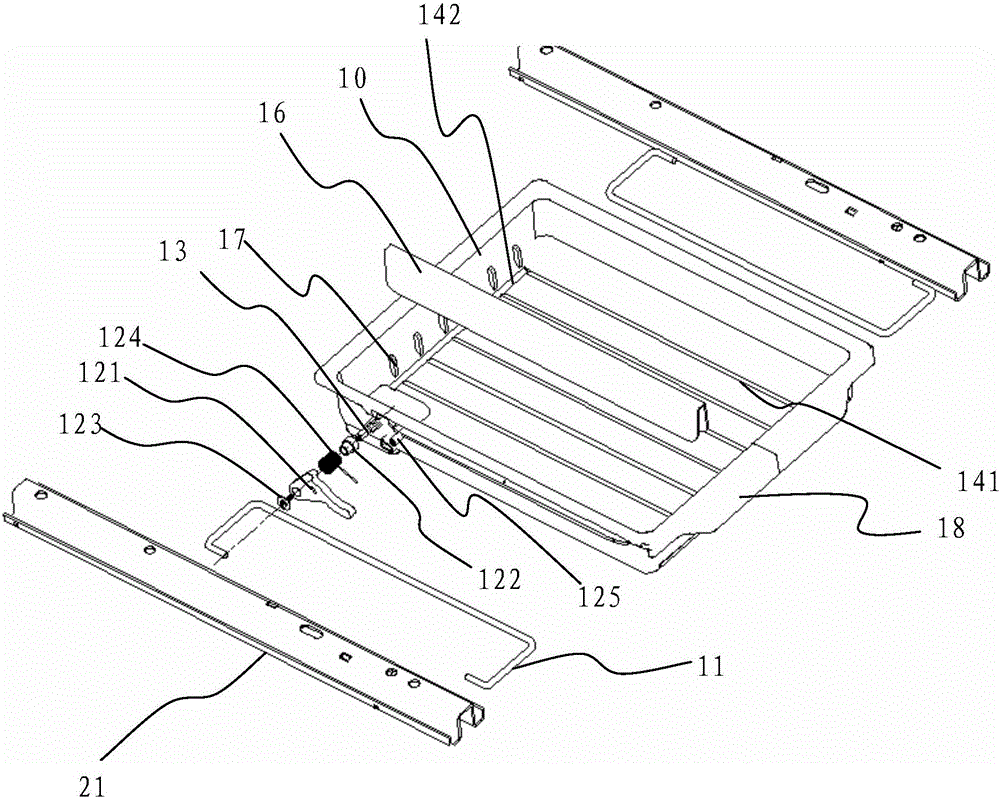

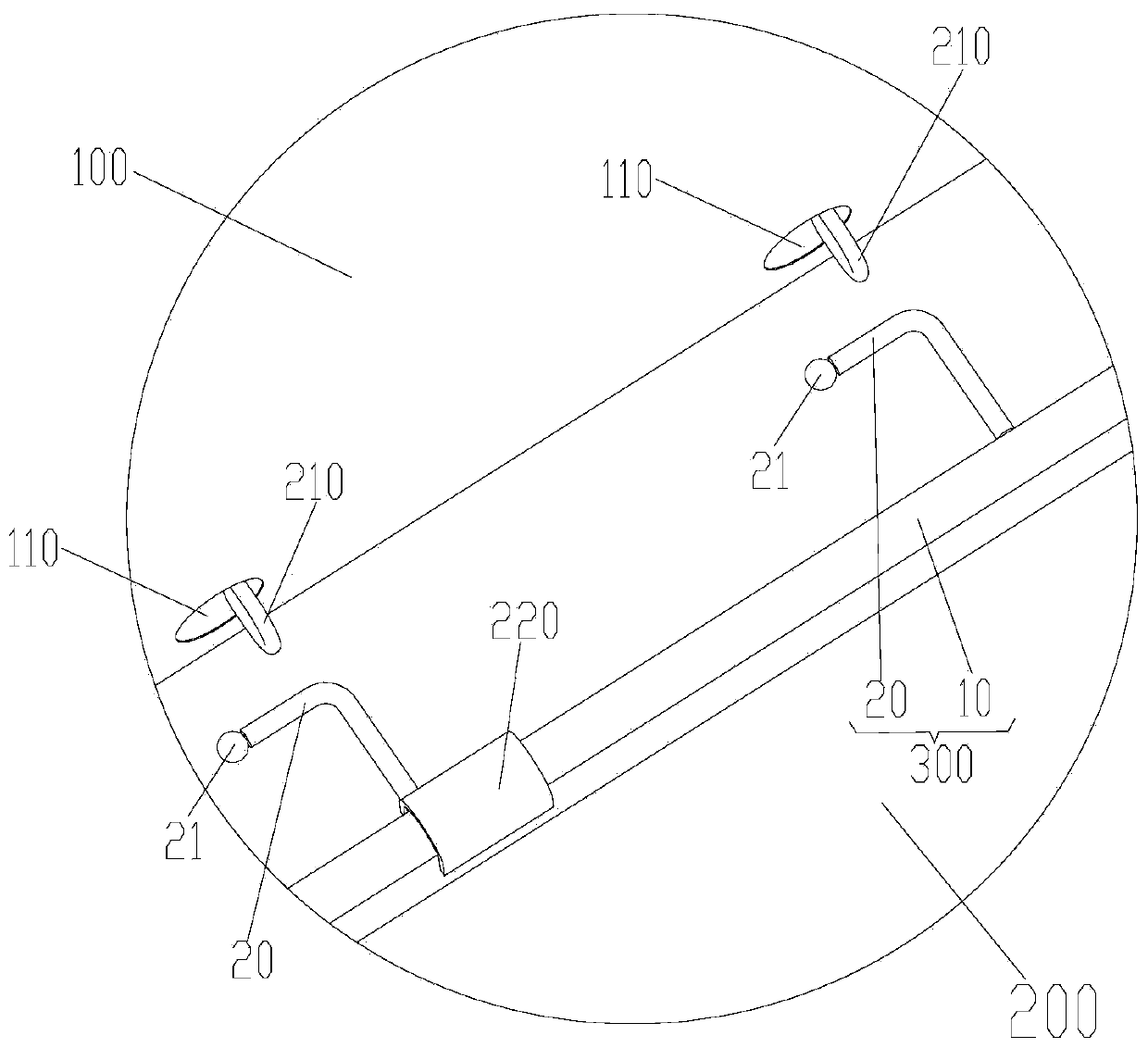

Automobile seat storage box device

ActiveCN103738249AMeet the convenience of storage at the same timeReduce frequencyPassenger spaceRacks dispositionCar seatInterior space

The invention discloses an automobile seat storage box device comprising a storage box body. Two sides of the storage box body are provided with two guide channels respectively; the guide channels are slidably disposed on two guide rails respectively; the guide rails are fixed on a seat slide rail below an automobile seat. The front end of each guide rail is provided with a limit part. The side, corresponding to the limit part, of the storage box body is provided with a lock handle. The first end of the locking handle is provided with a push part, and the second end of the locking handle is provided with a holding part used for holding against the limit part. One side of the storage box body is provided with a limit post. A spring driving the push part to hold against the limit post is arranged between the locking handle and the storage box body. The storage box body is disposed below the automobile seat, requires small excess interior space of an automobile and is convenient to operate, demount and clean, and frequency of using plastic tapes to place trash is greatly reduced.

Owner:YANFENG ADIENT SEATING CO LTD

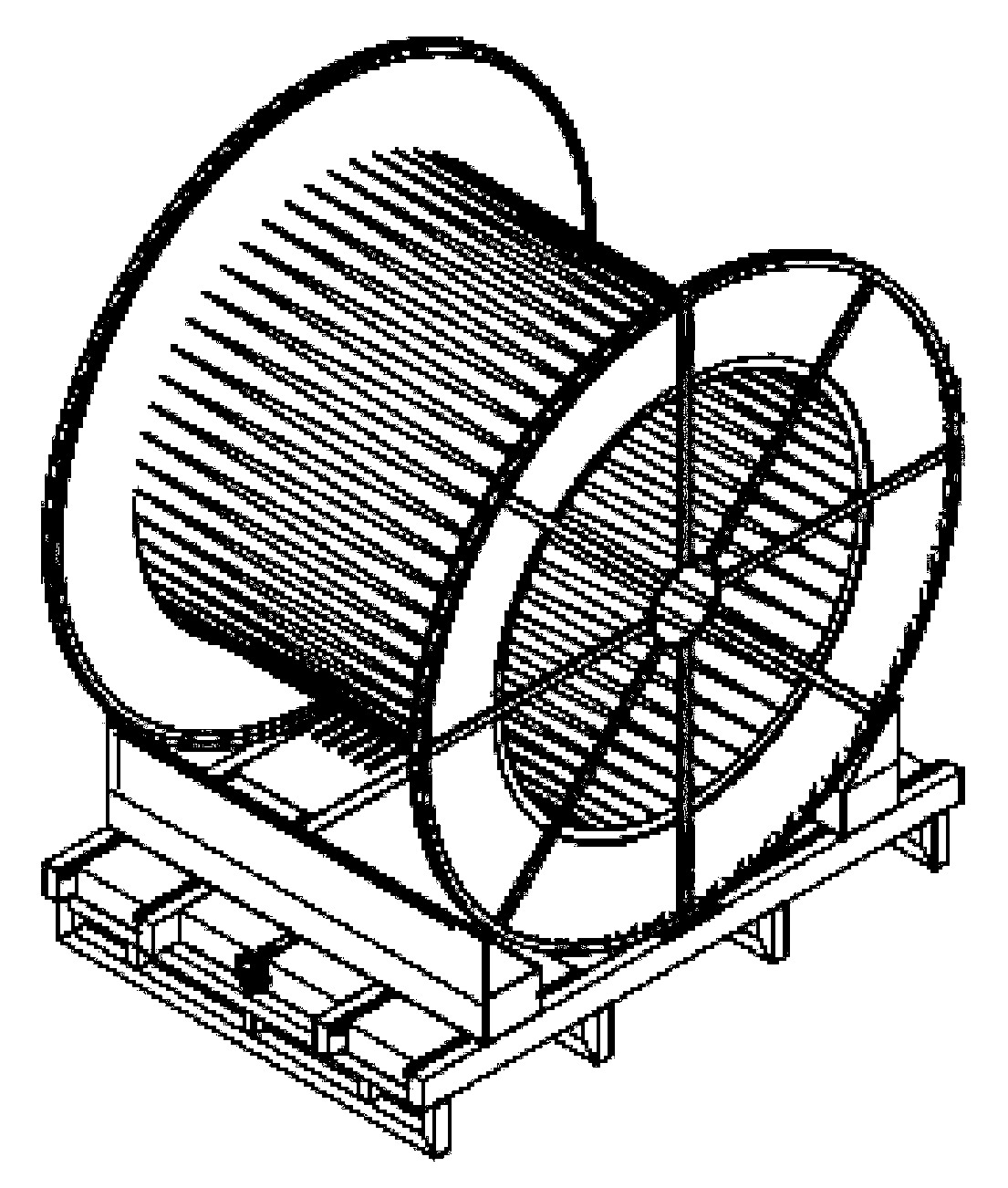

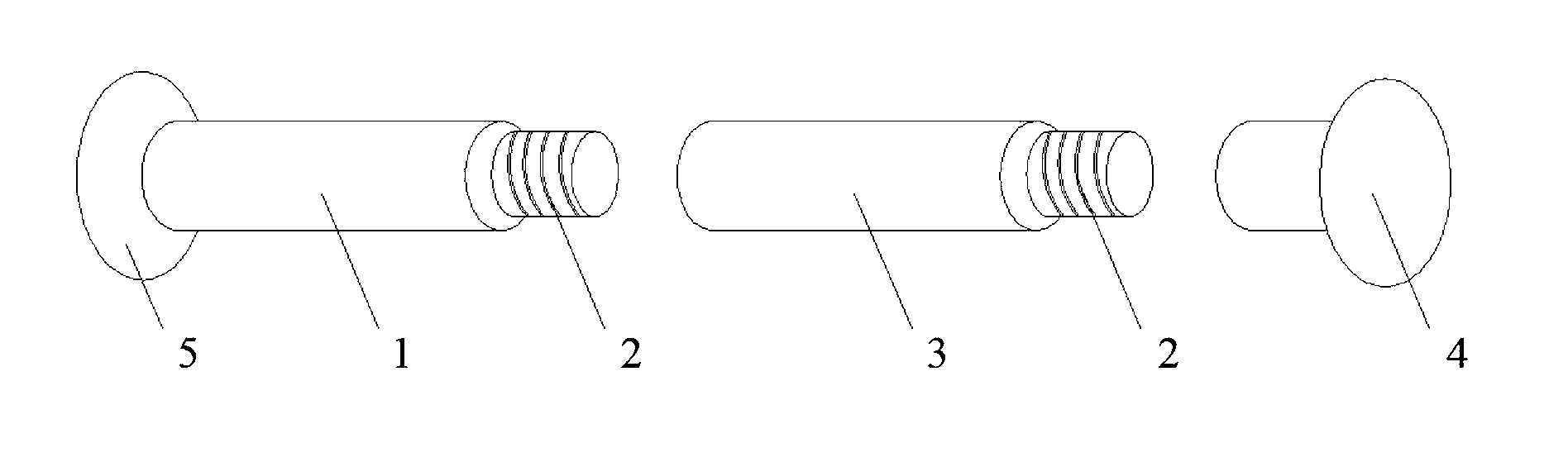

Yarn spool

The invention discloses a yarn spool which is characterized by comprising a main spool, an extension spool and a spool cap. The extension spool is connected with the main spool in a threaded manner, the spool cap is connected with the extension spool in a threaded manner, the main spool, the extension spool and the spool cap are rotators, the spool cap is convex, and a retainer plate is formed at a free end of the main spool. The yarn spool consisting of the main spool, the extension spool and the spool cap in threaded manner is simple in structure, convenient to mount, firm in connection and durable. The retainer plate and the convex spool cap formed at two ends of the yarn spool have certain blocking effect to yarns on the spool, thereby guaranteeing the yarns against falling off the yarn spool.

Owner:WUJIANG CITY XINSIYUAN TEXTILE

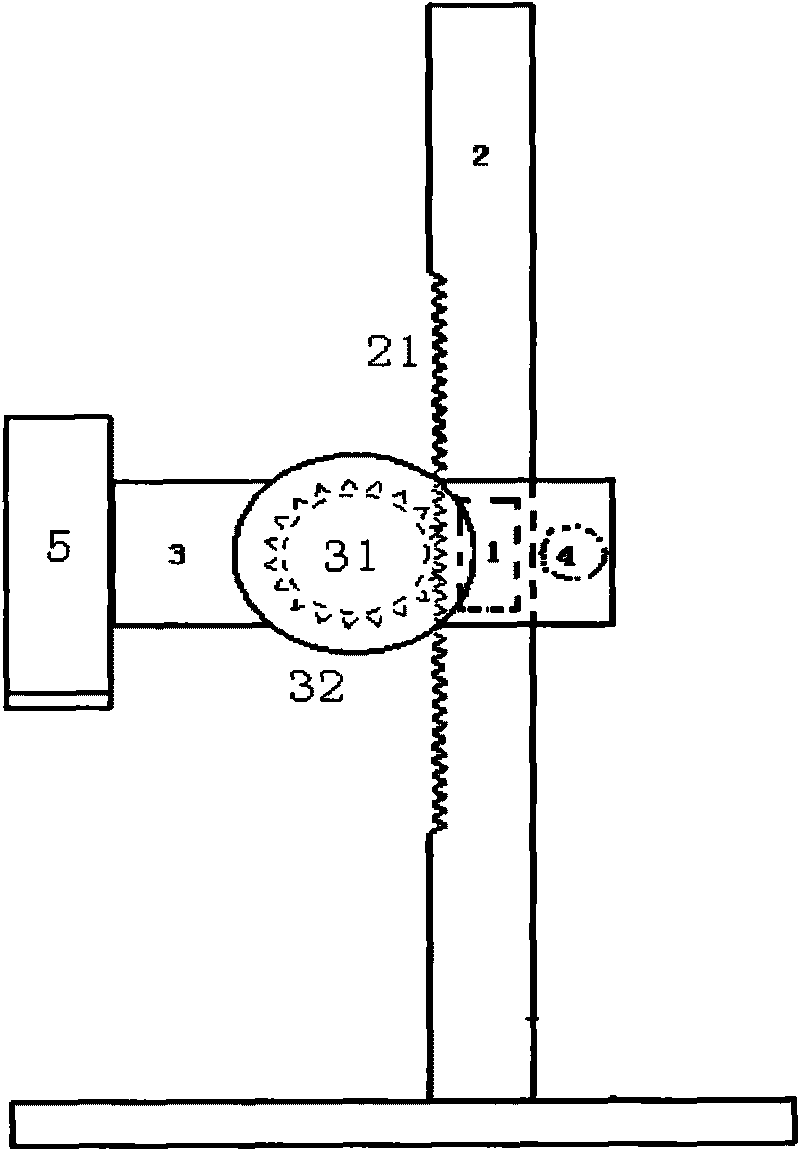

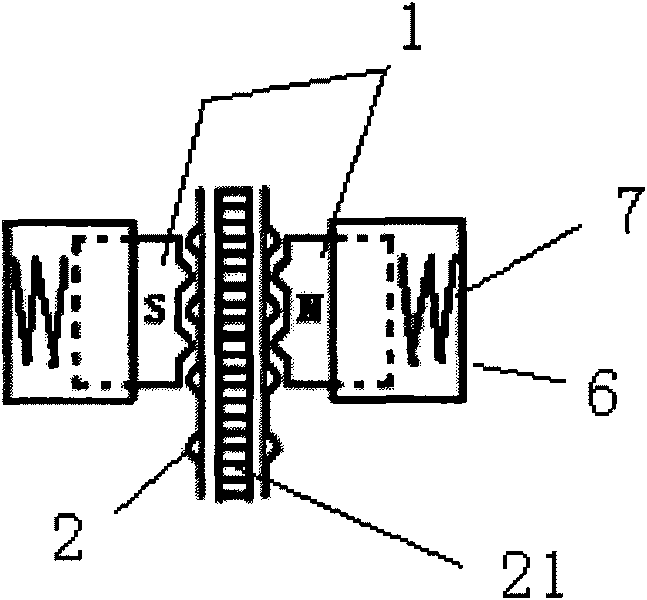

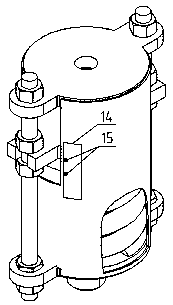

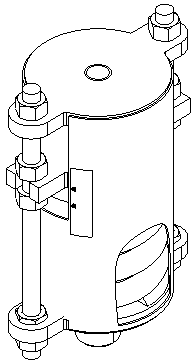

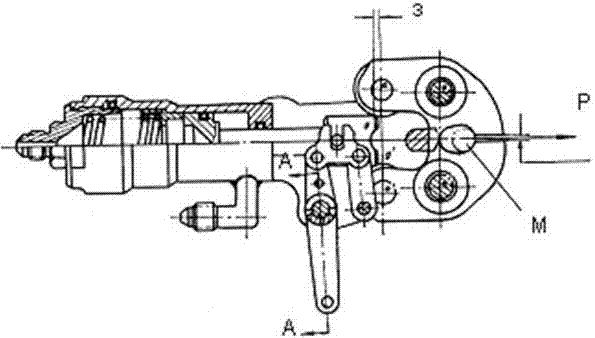

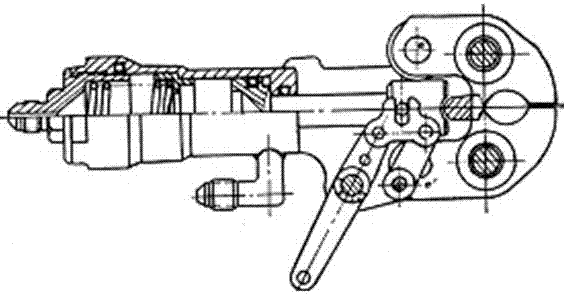

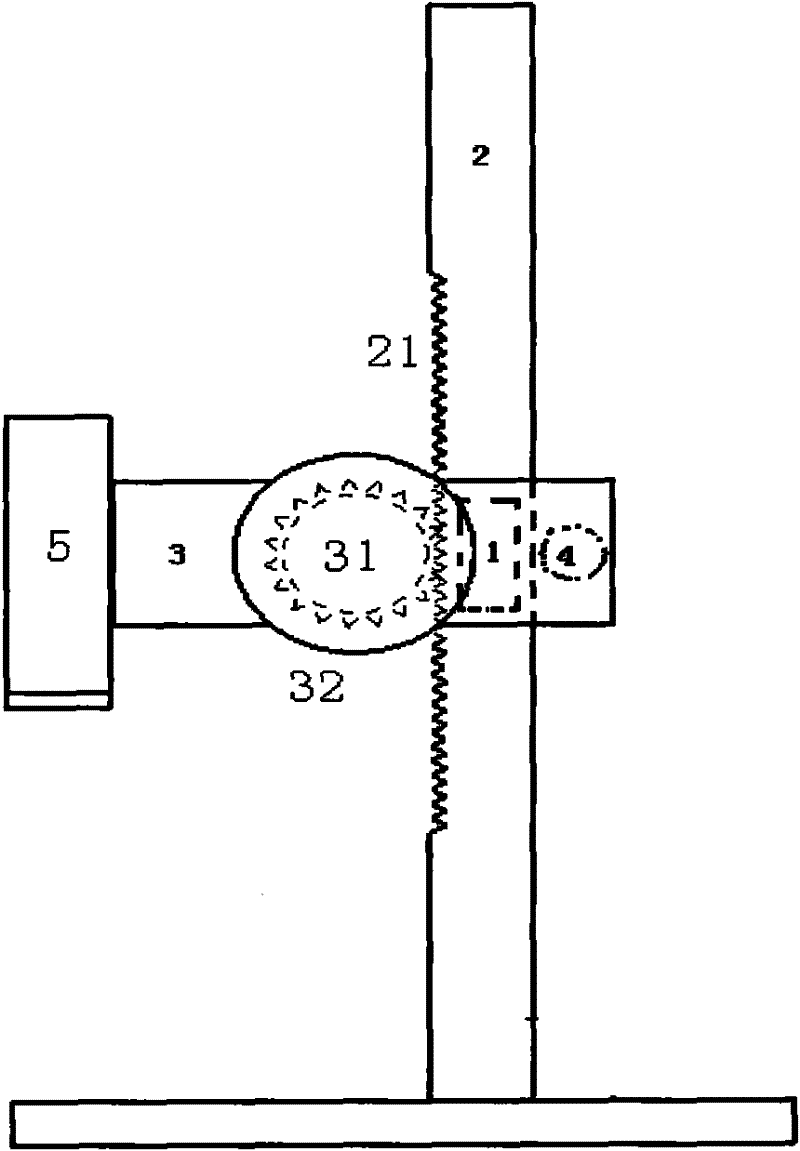

Magnetic stop mechanism in portable lifting device

InactiveCN101710492AIncrease viscous resistanceReliable stop functionInstrumental componentsViscous resistanceMoving parts

The invention discloses a magnetic stop mechanism in a portable lifting device. The magnetic stop mechanism comprises a strongly magnetic sliding block group, a slideguide, a moving part with hangers and an adjusting roller, wherein a pair of strongly magnetic sliding blocks in the strongly magnetic sliding block group are separately absorbed on the two sides of the slideguide, the N poles and S poles of the pair of the strongly magnetic sliding blocks are arranged oppositely; the strongly magnetic sliding block group is embedded in the moving part with hangers; the slideguide is provided with a rack, the moving part with hangers is provided with a gear matched with the rack and a rotary handle used for rotating the gear; and the strongly magnetic sliding block is pushed by the moving part with hangers to move up and down along the slideguide. The magnetic stop mechanism of the invention utilizes magnetic adsorption to increase the viscous resistance between the moving part and the fixed part of the lifting device, thus realizing stable stop function without affecting free lifting and being applicable to instruments with accurate and light structure.

Owner:NANJING UNIV

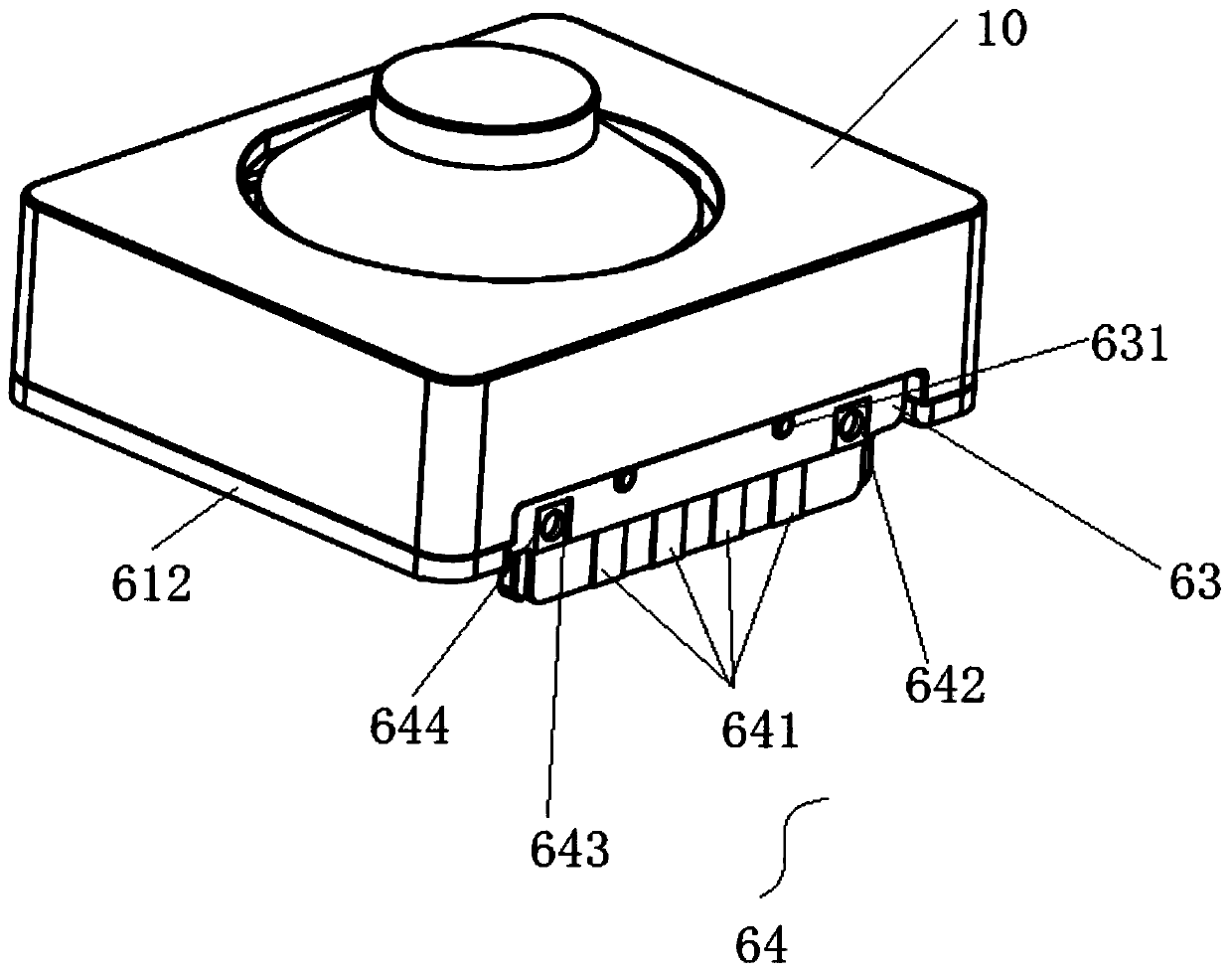

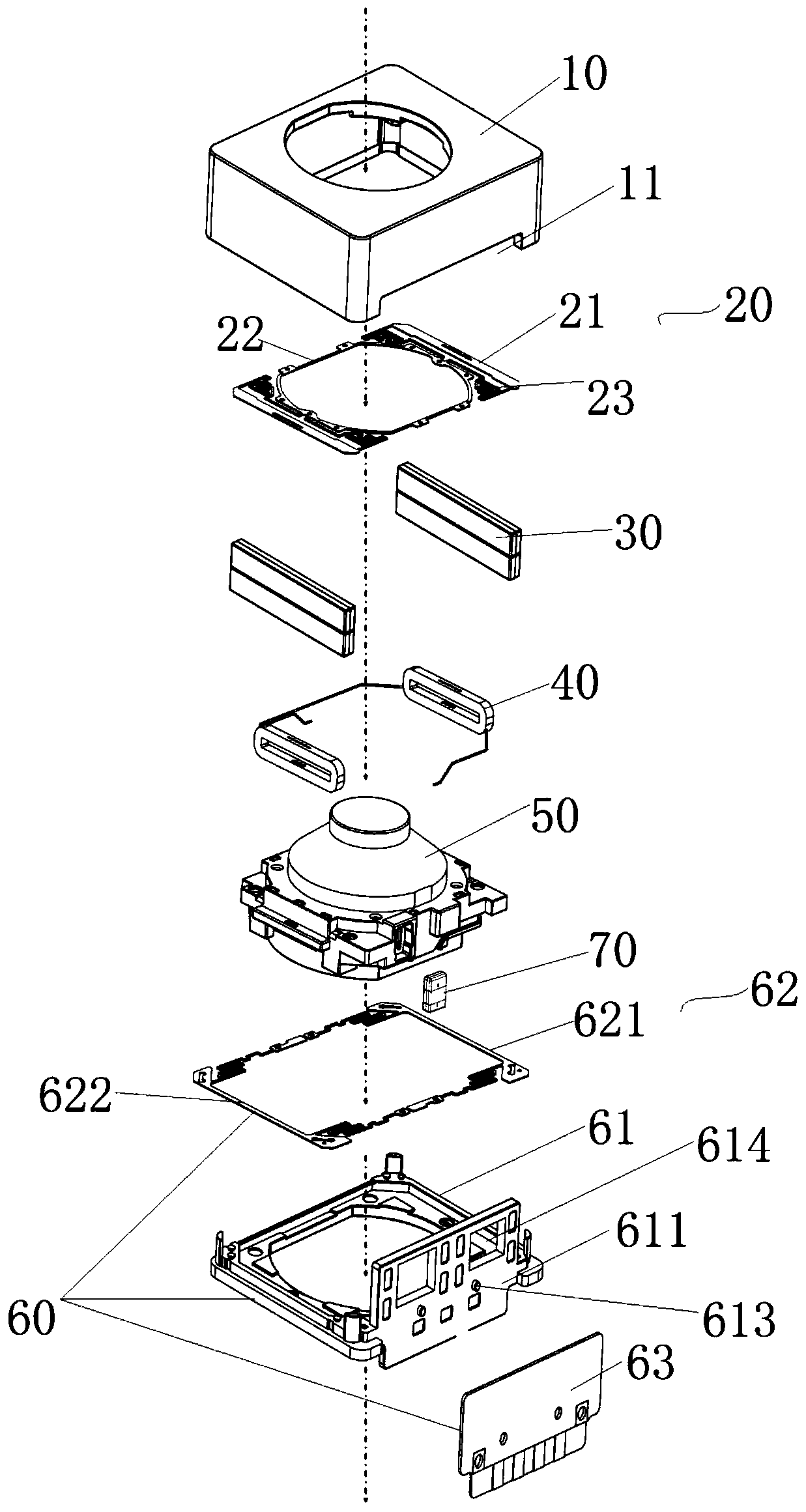

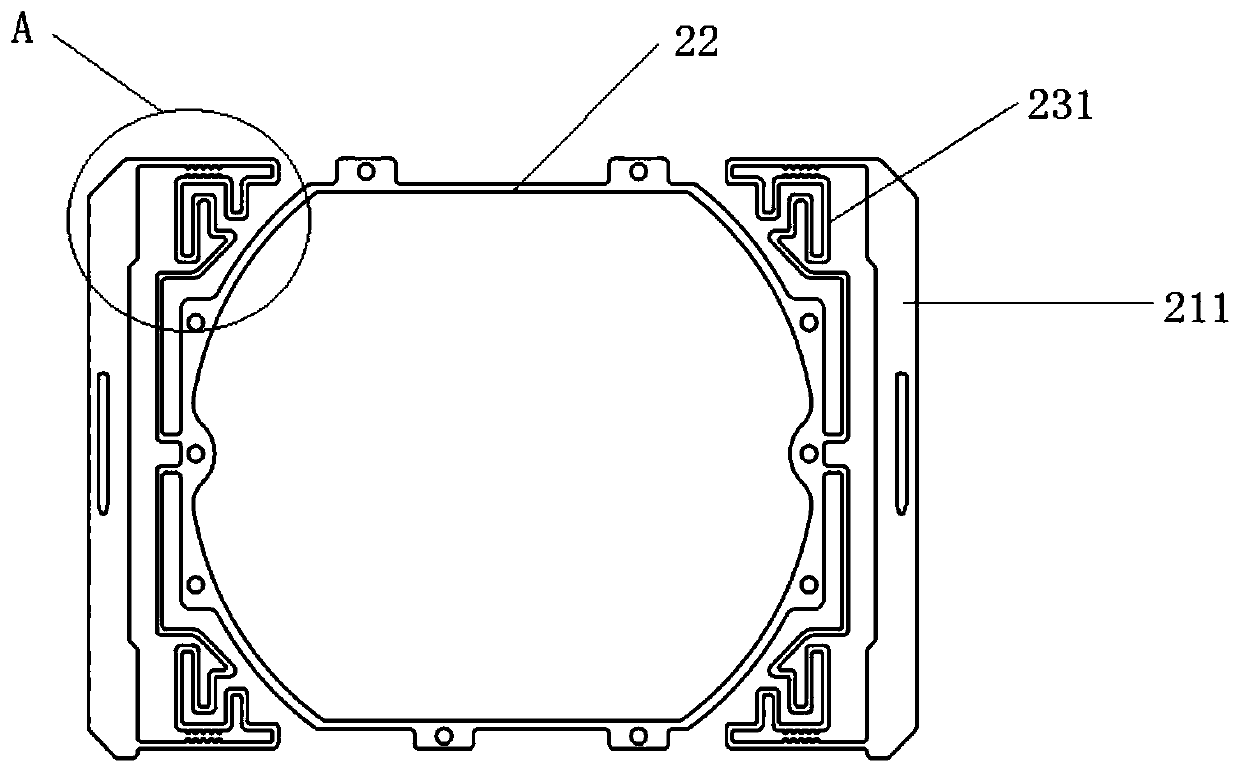

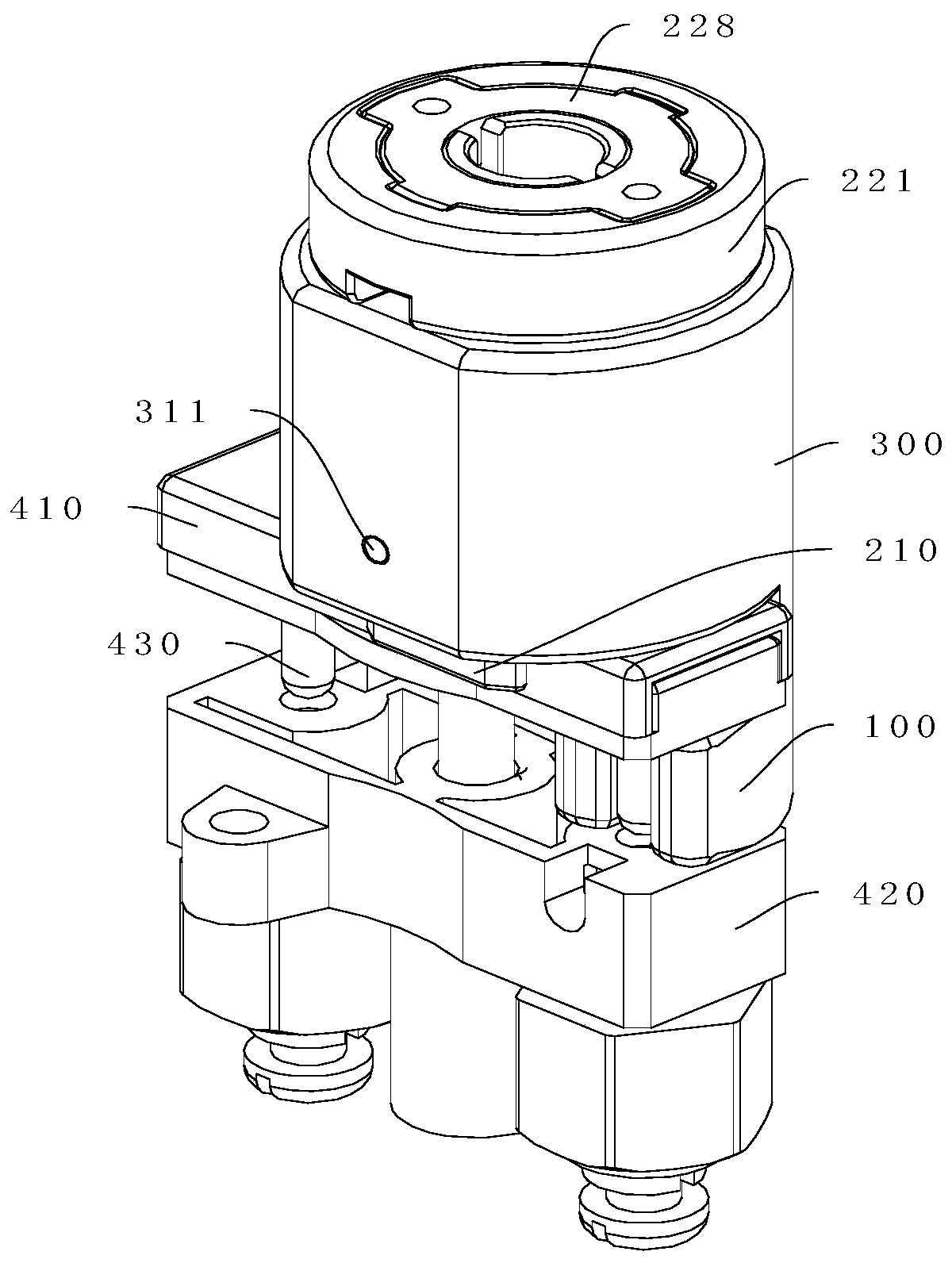

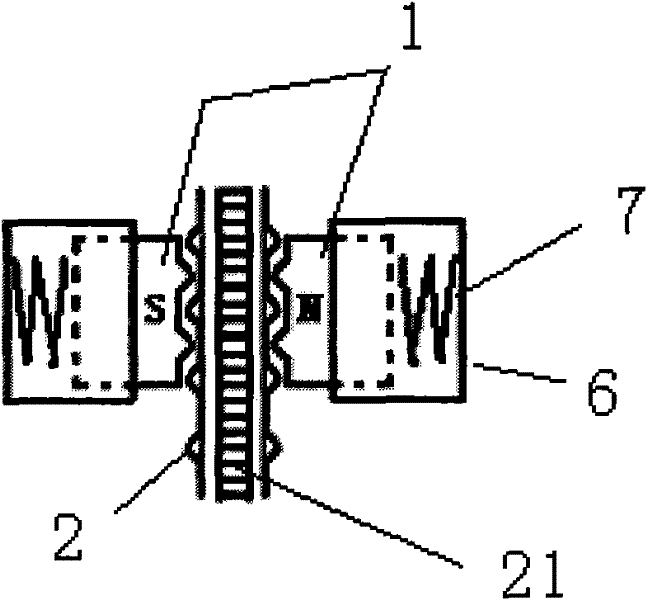

Lens driving motor, camera and mobile terminal

PendingCN111025819AEasy to useGuaranteed cushioning and shock absorption performanceProjector focusing arrangementCamera focusing arrangementEngineeringDrive motor

The invention provides a lens driving motor, a camera and a mobile terminal. The lens driving motor comprises a shell, an upper spring, a driving magnet, a driving coil, a lens supporting body and a lower cover assembly. The shell is arranged on the lower cover assembly to form an accommodating space between the shell and the lower cover assembly; the driving magnet, the driving coil and the lenssupporting body are all located in the accommodating space, the driving coil is arranged on the lens supporting body, the driving magnet is arranged corresponding to the driving coil, the upper springis arranged between the shell and the lens supporting body. The upper spring comprises an outer ring structure connected with the shell, an inner ring structure connected with the lens supporting body, and a middle structure through which the outer ring structure and the inner ring structure are connected. A plurality of protruding parts are arranged on the middle structure, and at least two protruding parts extend in the direction close to each other to form an oiling gap. The lens driving motor solves the problem of poor use performance of the lens driving motor in the prior art.

Owner:SHANGHAI BILLU ELECTRONICS CO LTD

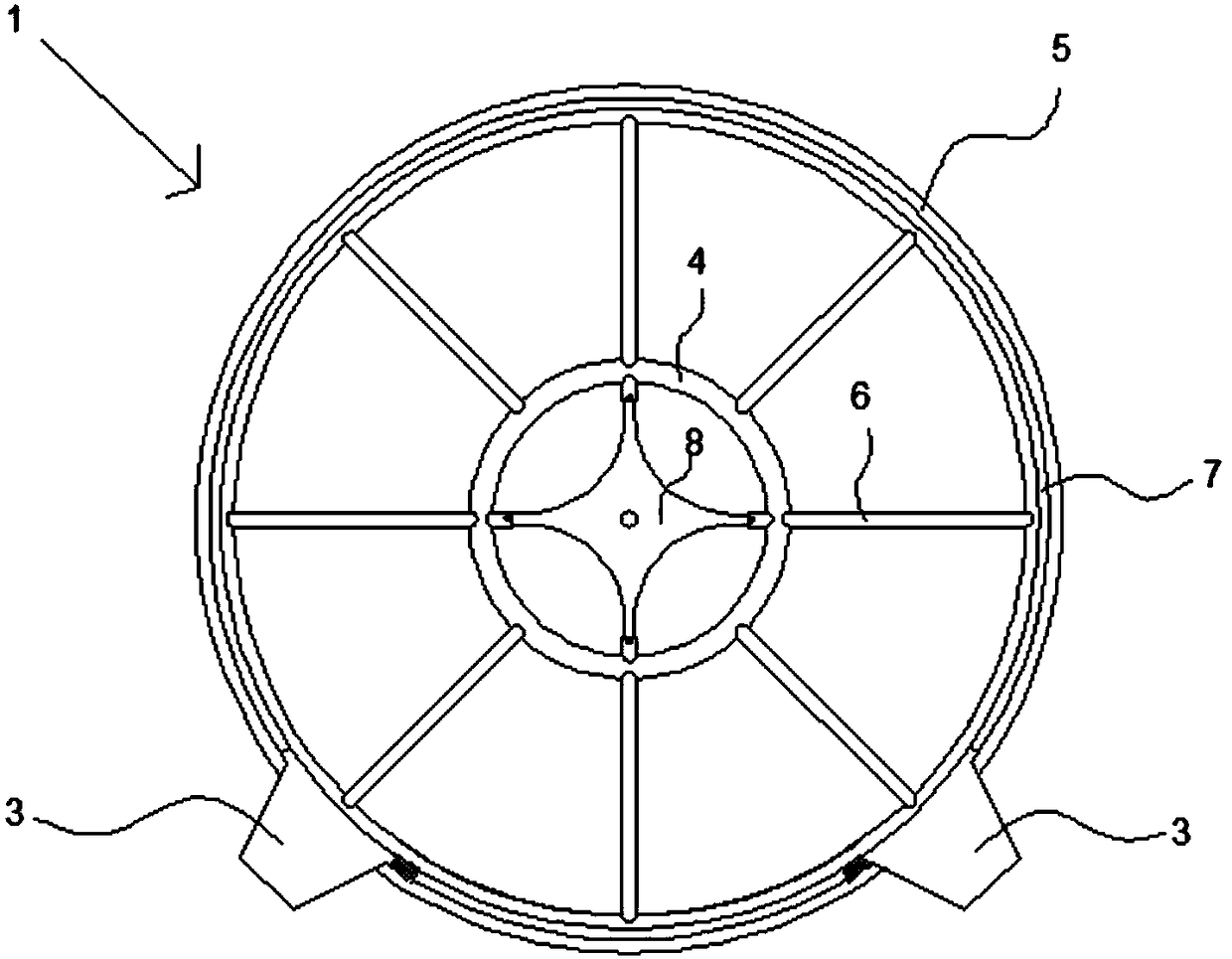

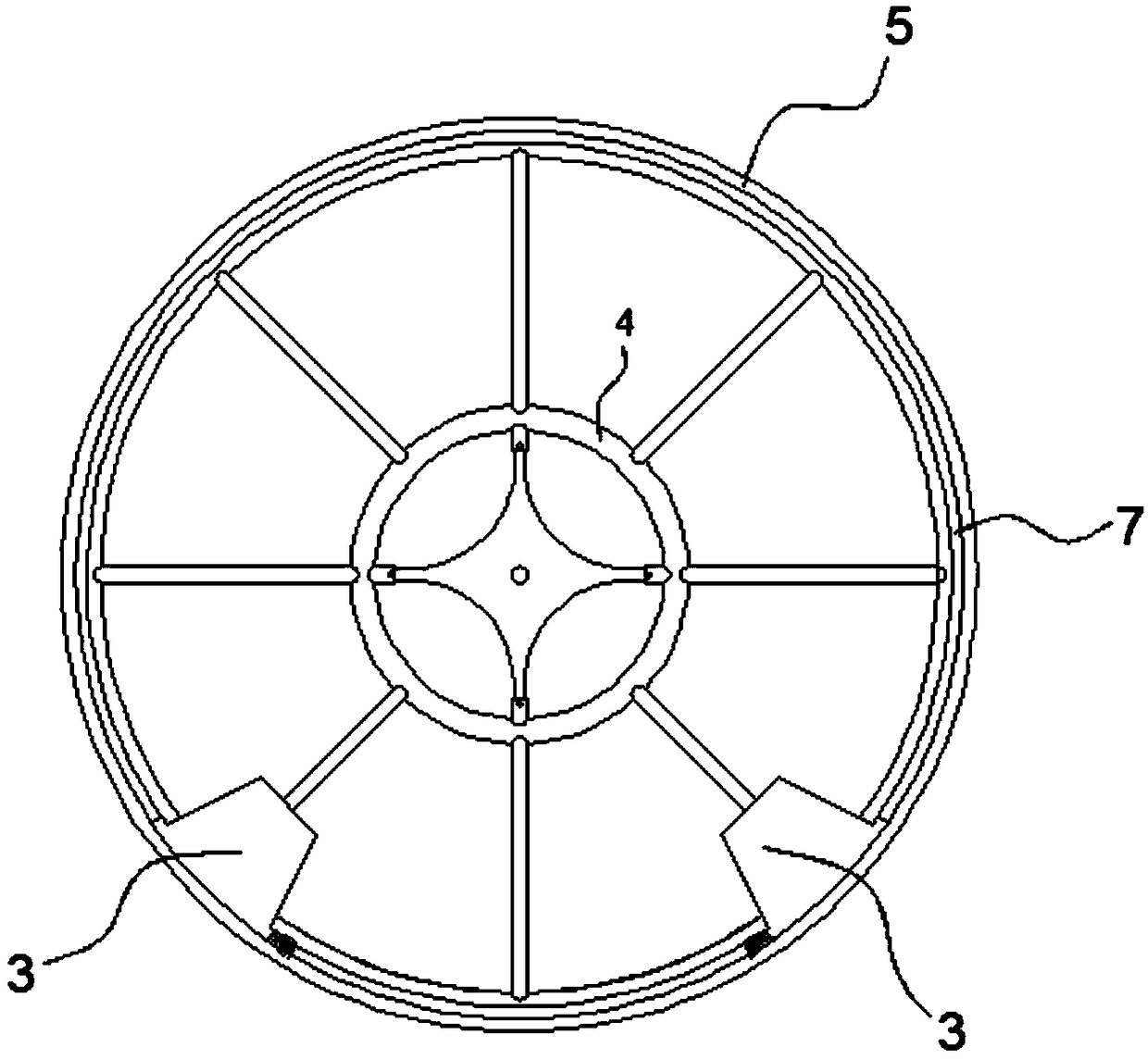

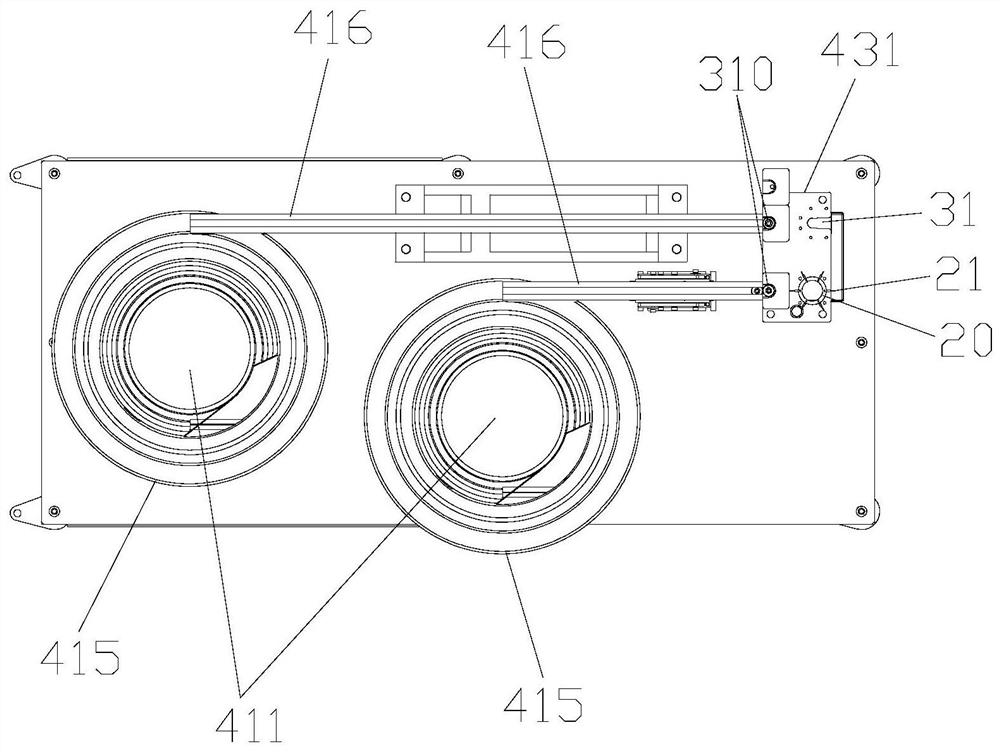

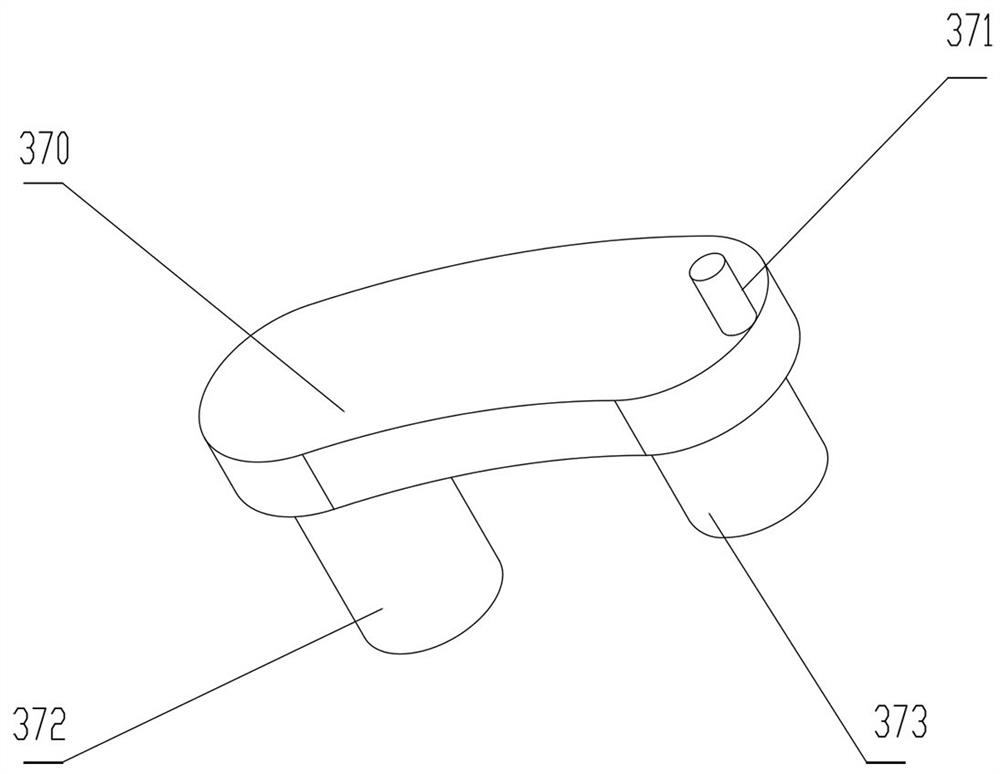

Steel wire rope coiling device

The invention discloses a steel wire rope coiling device. The steel wire rope coiling device comprises rotation wheels, transverse rods and stop devices. Each rotation wheel comprises an inner ring and an outer ring which are fixed through a supporting rod. The outer side faces of the outer rings are provided with installing grooves around the outer ring circumference. The stop devices are embedded in the installing grooves and can do the circumference movement around the outer rings. Each stop device comprises a base, a left stand column, a right stand column, an overturning plate, a rotationshaft and a spring, wherein the left stand column and the right stand column are fixed to the two ends of the base, the base is embedded in the corresponding installing groove, the width of the baseis larger than the width of the left stand column and the width of the right stand column, one end of the rotation shaft is hinged to the left stand column, the other end of the rotation shaft is hinged to the right stand column, and the side, close to the overturning plate, of the right stand column is provided with a limiting groove; and the overturning plate is in an isosceles trapezoid shape,the rotation shaft is arranged on the upper side of the lower bottom edge of the overturning plate and is integrally formed with the overturning plate, and the spring sleeves the part, between the left stand column and the overturning plate, of the rotation shaft. According to the steel wire rope coiling device, the stop devices are additionally arranged, the rope coiling device can be conveniently fixed in the usage and storage process, the rope coiling device is prevented from rolling at random, and the practicability of the rope coiling device is improved.

Owner:陈勇

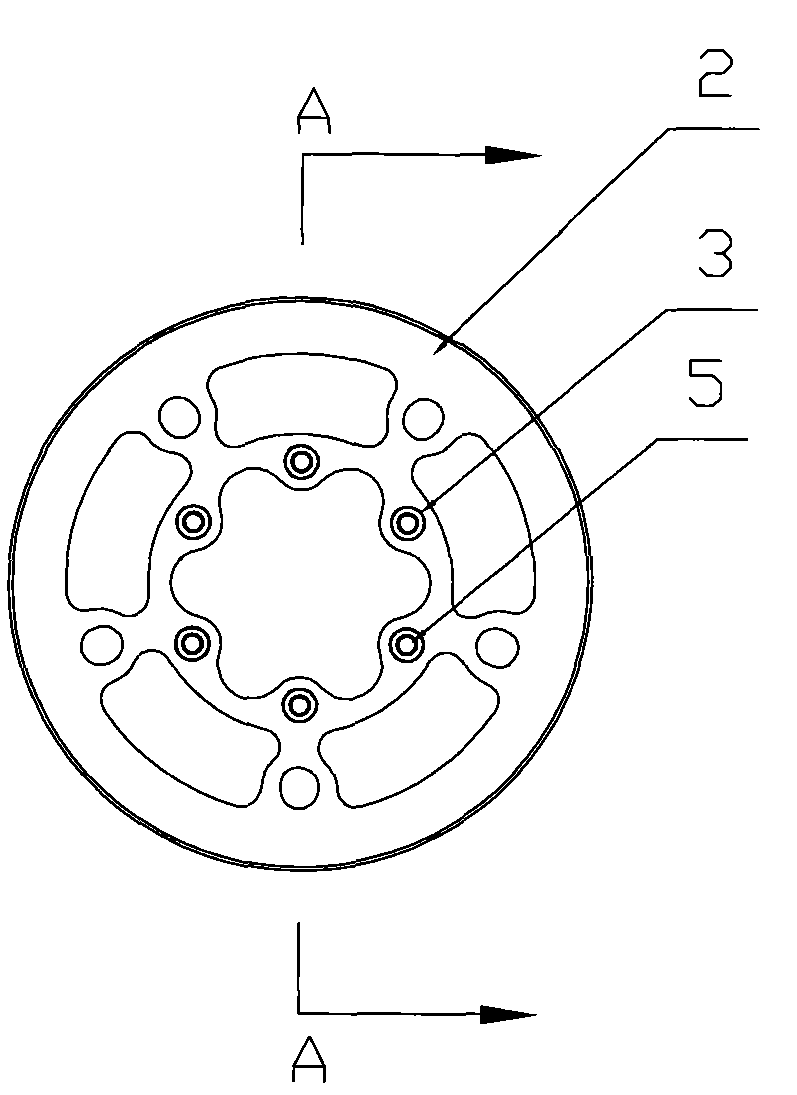

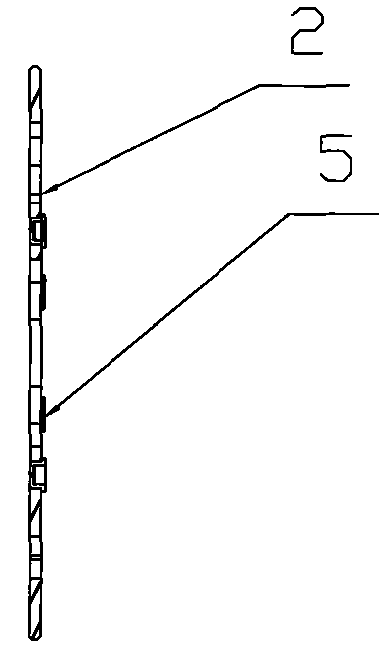

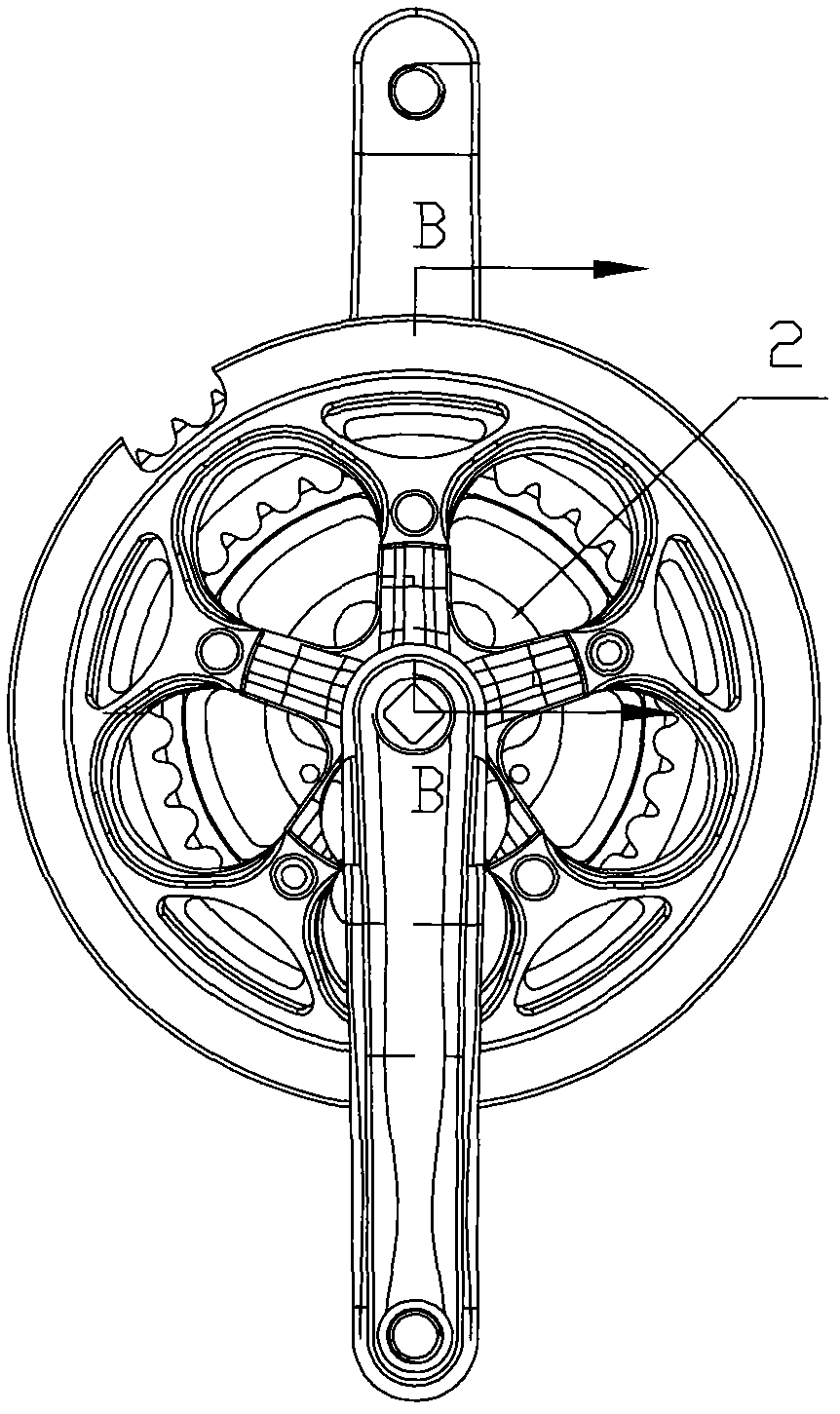

Installation structure of electric bicycle sensor

The invention discloses an installation structure of an electric bicycle sensor. By taking the using direction as reference, the inner side of an inner chain wheel of an electric bicycle is fixedly provided with an inner chain cover; the inner chain cover is provided with a magnetic-steel head installing hole; and a magnetic-steel head of the electric bicycle sensor can be fixedly inserted in the magnetic-steel installing hole rightly. The sensor is installed on the inner chain cover, so that the signal of the sensor is stable; simultaneously the distance from the center of the bicycle body to a central disc is effectively reduced, so that the speed of the electric bicycle can be changed flexibly; and meanwhile, the inner chain cover plays a role of backstopping a chain, thus preventing the chain from falling down inwards.

Owner:ACTIVE CYCLES

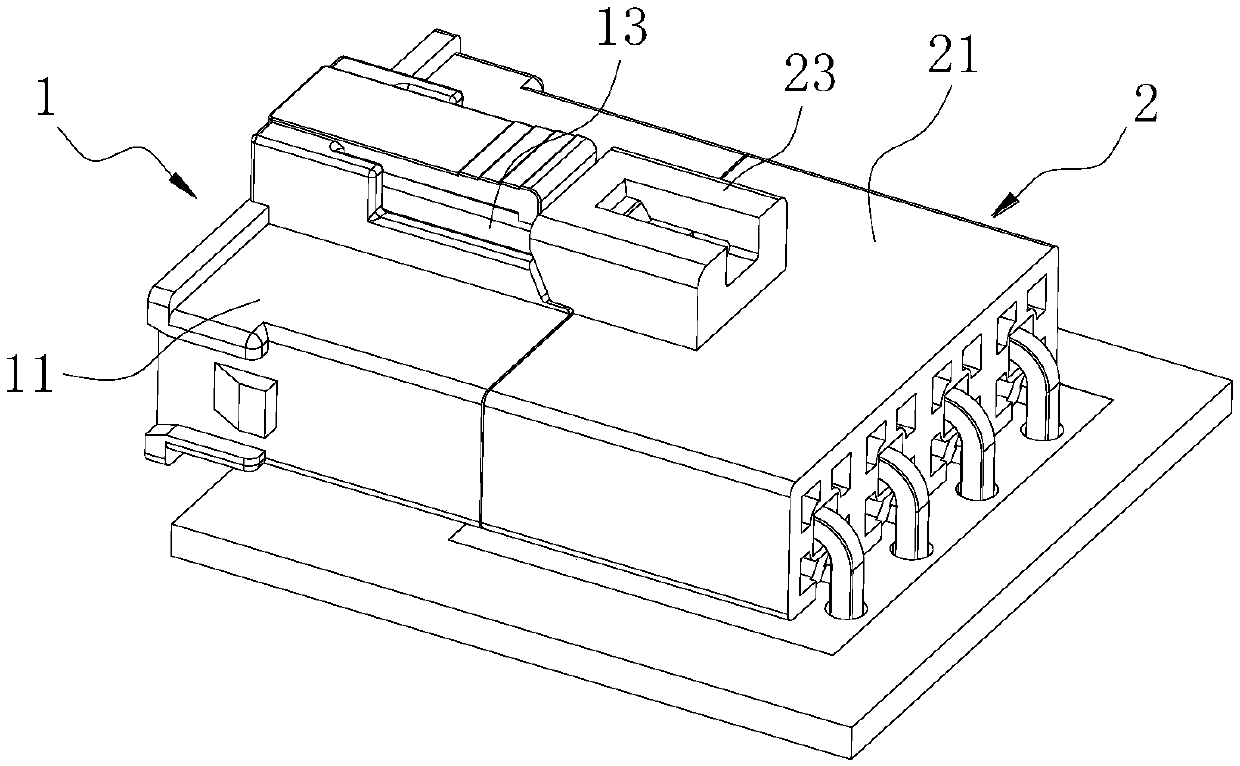

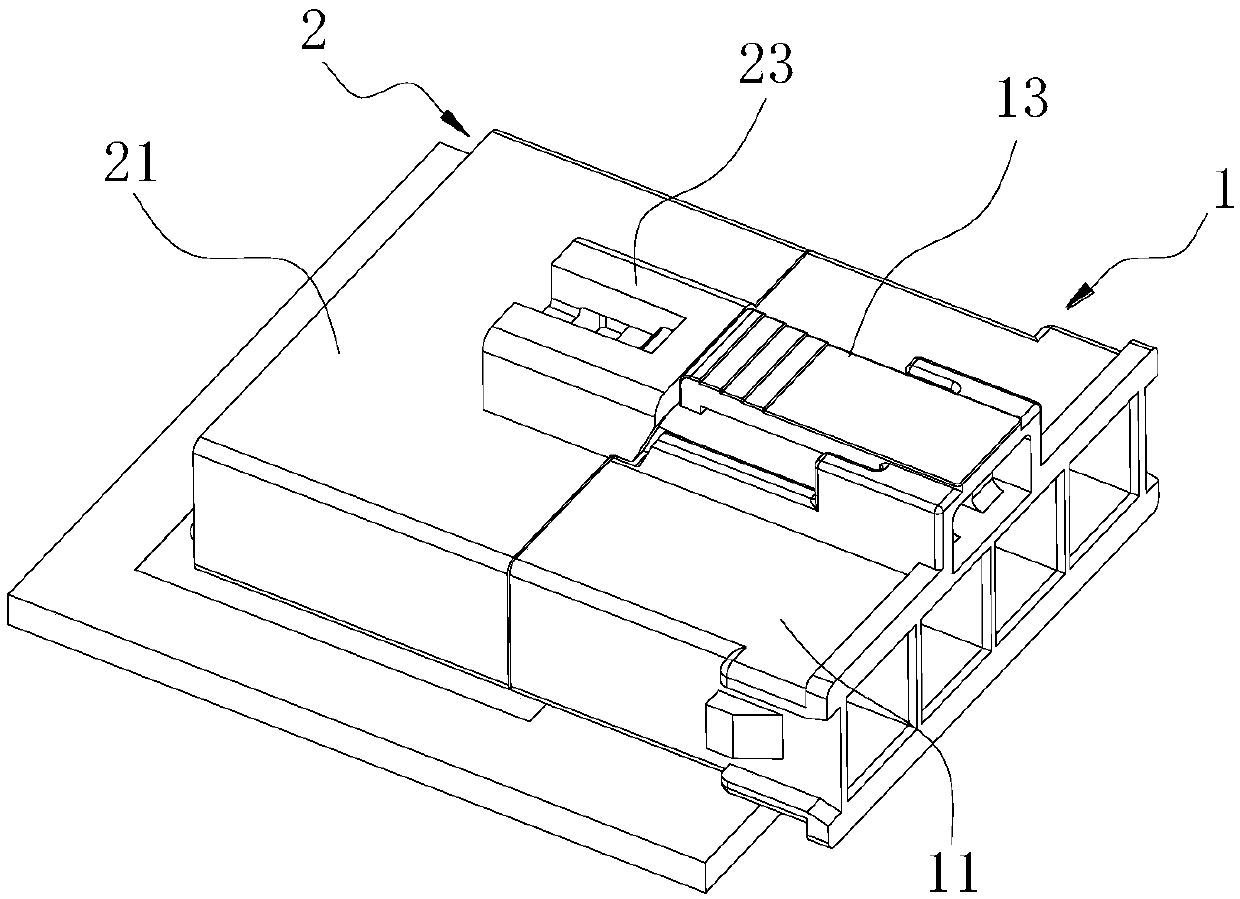

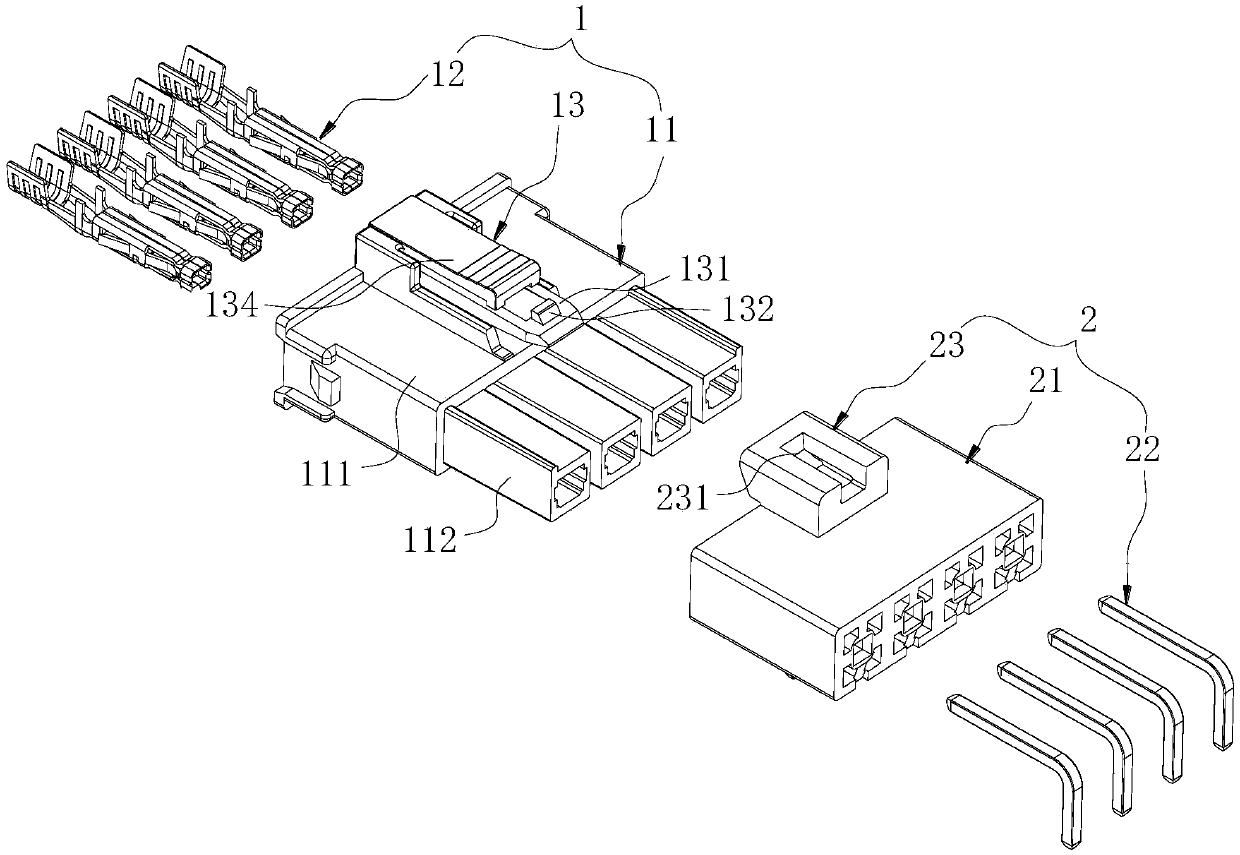

Electric connector and connector combination with electric connector

ActiveCN110534969APlay a stop rolePrevents inelastic deformation or even damageCouplings bases/casesElectricityEngineering

Owner:MOLEX INTERCONNECT SHANGHAI +1

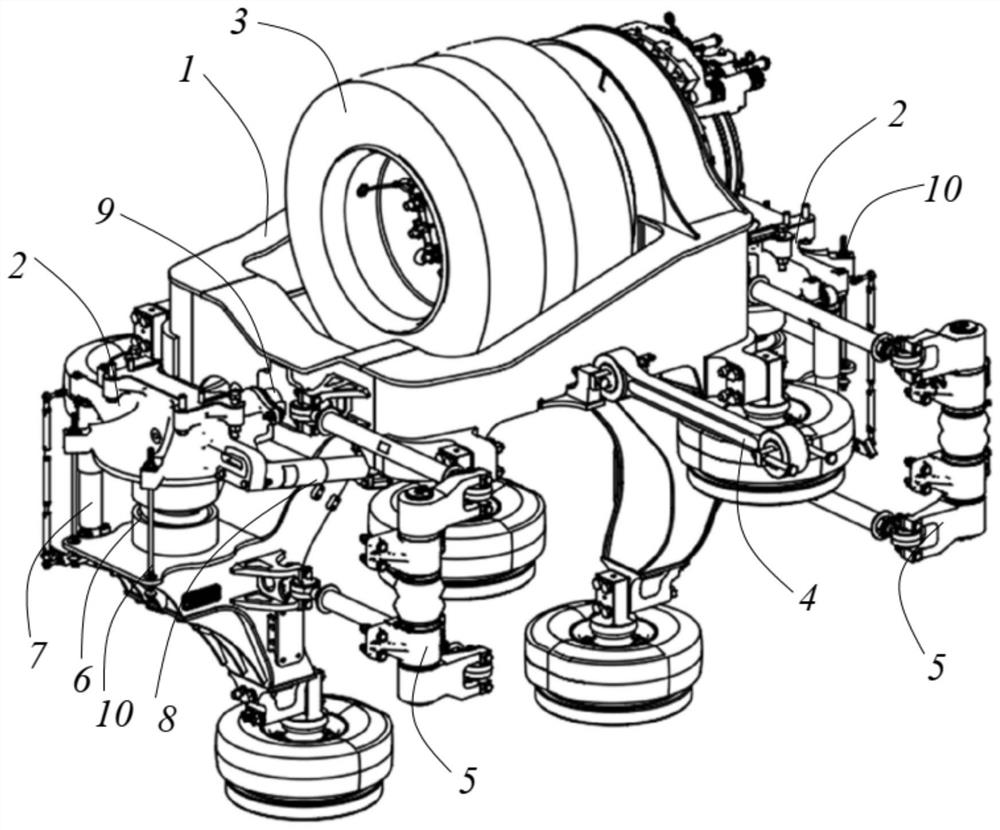

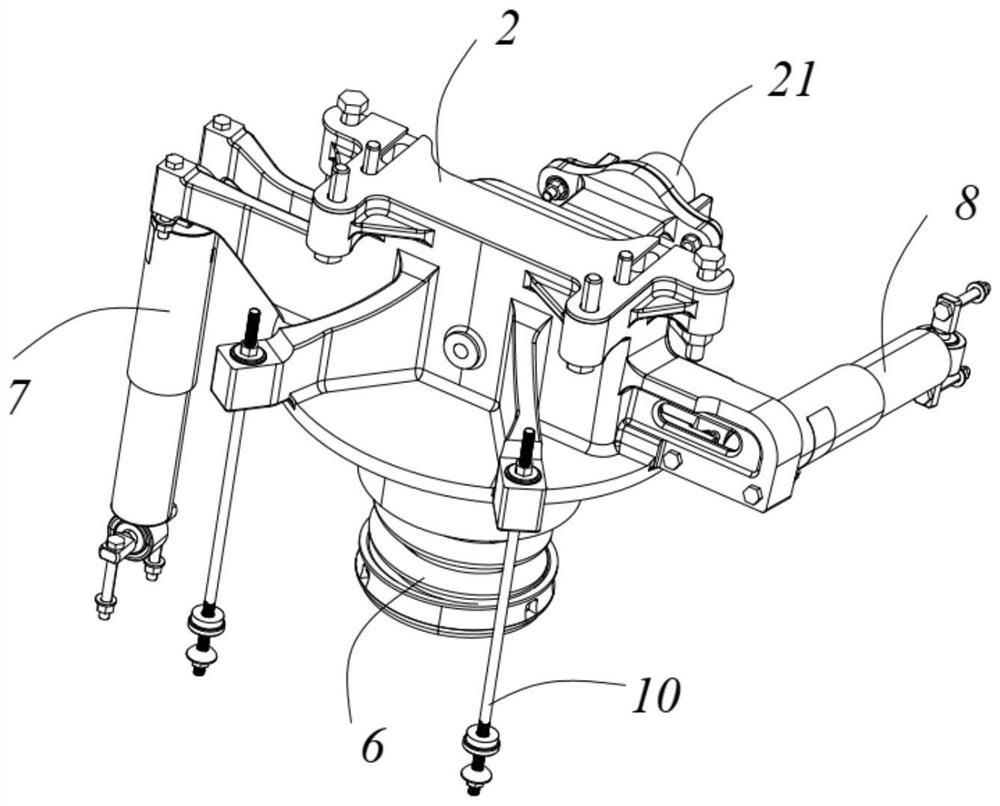

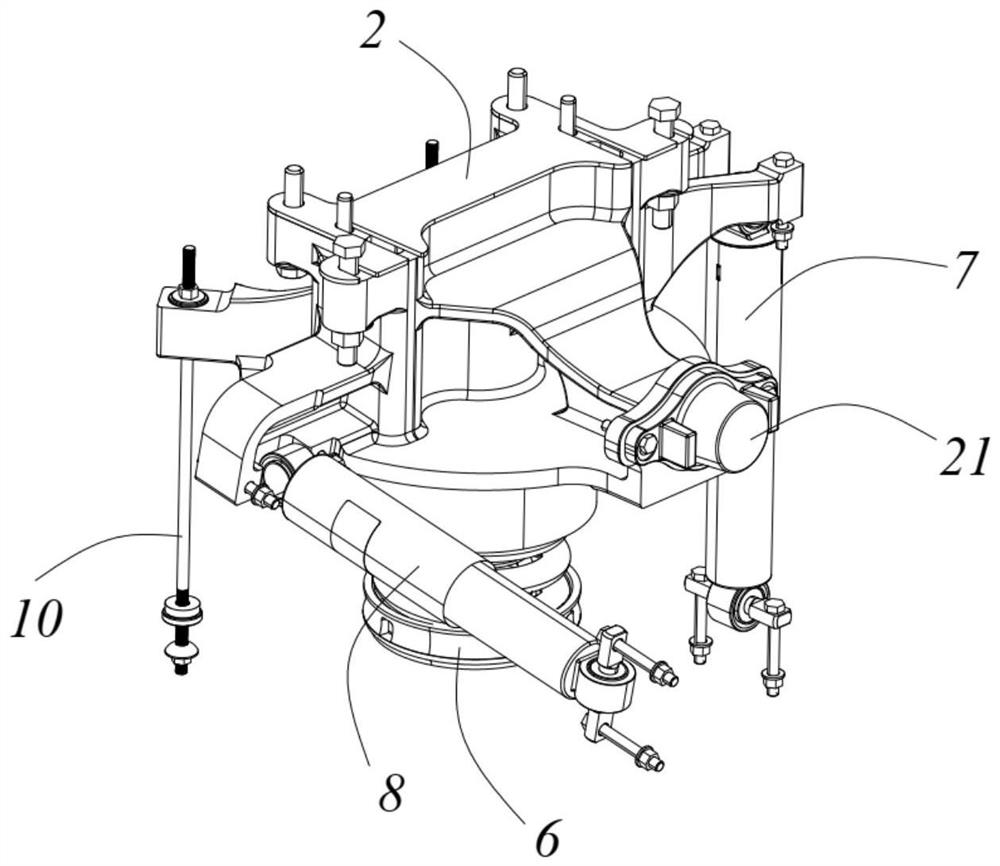

Steel spring structure, bogie and rail vehicle with same

The invention relates to a steel spring structure, a bogie and a rail vehicle with same. The steel spring structure comprises an upper positioning groove and a lower positioning groove, a steel springassembly is arranged between the upper positioning groove and the lower positioning groove, the steel spring assembly comprises a steel spring inner ring and a steel spring outer ring, and a first rubber shock pad is arranged in the upper positioning groove. A second rubber shock pad is arranged in the lower positioning groove, and a first extending end and a second extending end are matched to form a vertical stop. The bogie comprises a bogie support and mounting seats, a steel spring structure is arranged between the bogie support and the mounting seats, a traction rod is arranged between the bogie support and a railway vehicle body, and an anti-nodding device, a vertical shock absorber and a transverse shock absorber are arranged between each mounting seat and the railway vehicle body.And a transverse stopper is arranged between each mounting seat and the bogie support. The purpose of double supporting is achieved through the steel spring assembly, transverse displacement can be achieved through the vertical stop block, impact and vibration are reduced, and riding comfort is improved.

Owner:中铁轨道交通装备有限公司

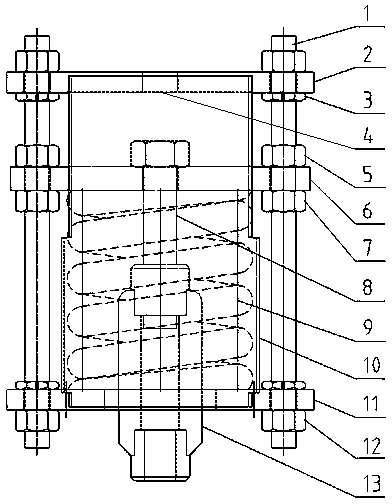

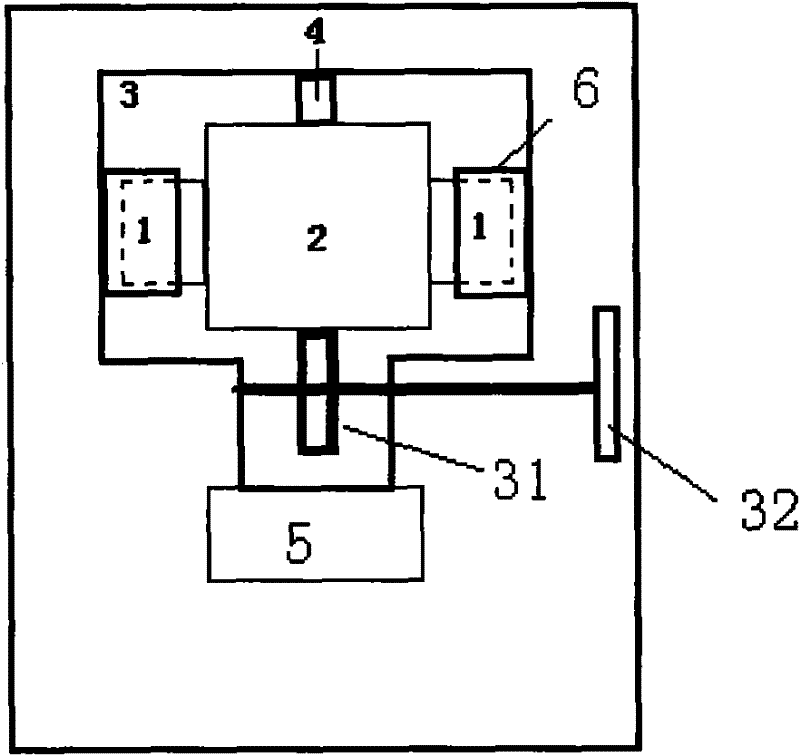

Overload prevention combined type variable spring supporter and hanger utilizing threaded rod to lock

PendingCN108869888ALow costEasy maintenancePipe supportsNon-rotating vibration suppressionAgricultural engineeringEngineering

The invention provides an overload prevention combined type variable spring supporter and hanger utilizing a threaded rod to lock. The overload prevention combined type variable spring supporter and hanger structurally comprises an upper cover plate, a spring pressure plate, a spring, a spring housing and a lower cover plate, wherein the spring pressure plate is arranged between the upper cover plate and the lower cover plate; the spring is mounted between the lower surface of the spring pressure plate and the upper surface of the lower cover plate; the spring housing is arranged outside the spring; the upper end of the spring housing is connected with and fixed to the upper cover plate; the lower end of the spring housing is connected with and fixed to the lower cover plate; one of two locking bolts penetrate through a hole in the left side of the upper cover plate, a bayonet in the left side of the spring pressure plate, and a hole in the left side of the lower cover plate; and the other locking bolt penetrates through a hole in the right side of the upper cover plate, a bayonet in the right side of the spring pressure plate, and a hole in the right side of the lower cover plate.The overload prevention combined type variable spring supporter has the advantages that (1) precise locking can be realized according to a measured value, and error influence is avoided; (2) a setting value can be modified, no replacement is required, and the cost is reduced; (3) locking again can be realized during overhaul and the operation is facilitated; and (4) with the adoption of a combined structure, the service life of a product is prolonged.

Owner:JIANGSU DALICHENG ELECTRICAL

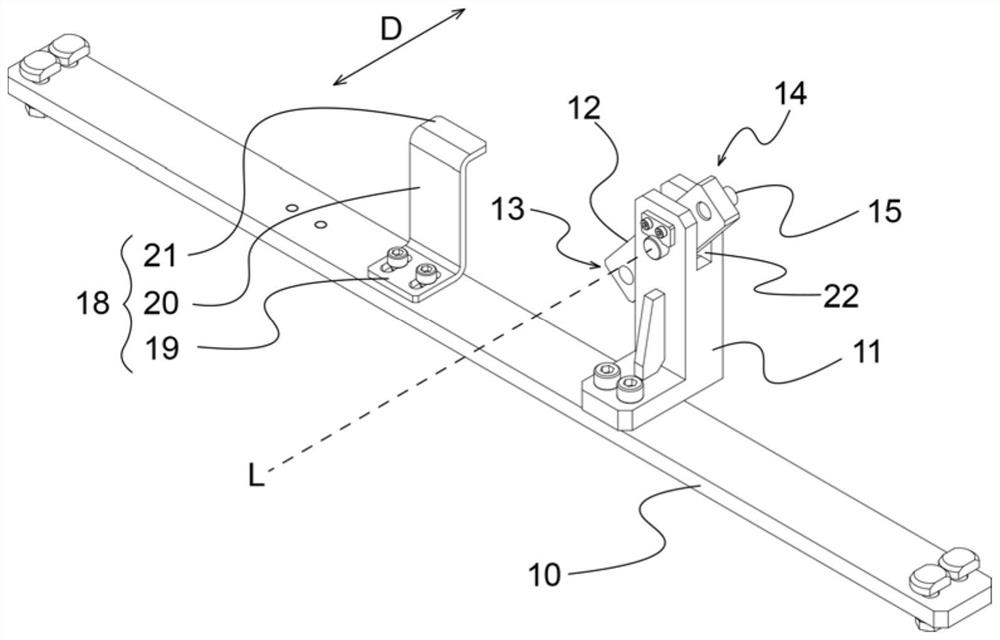

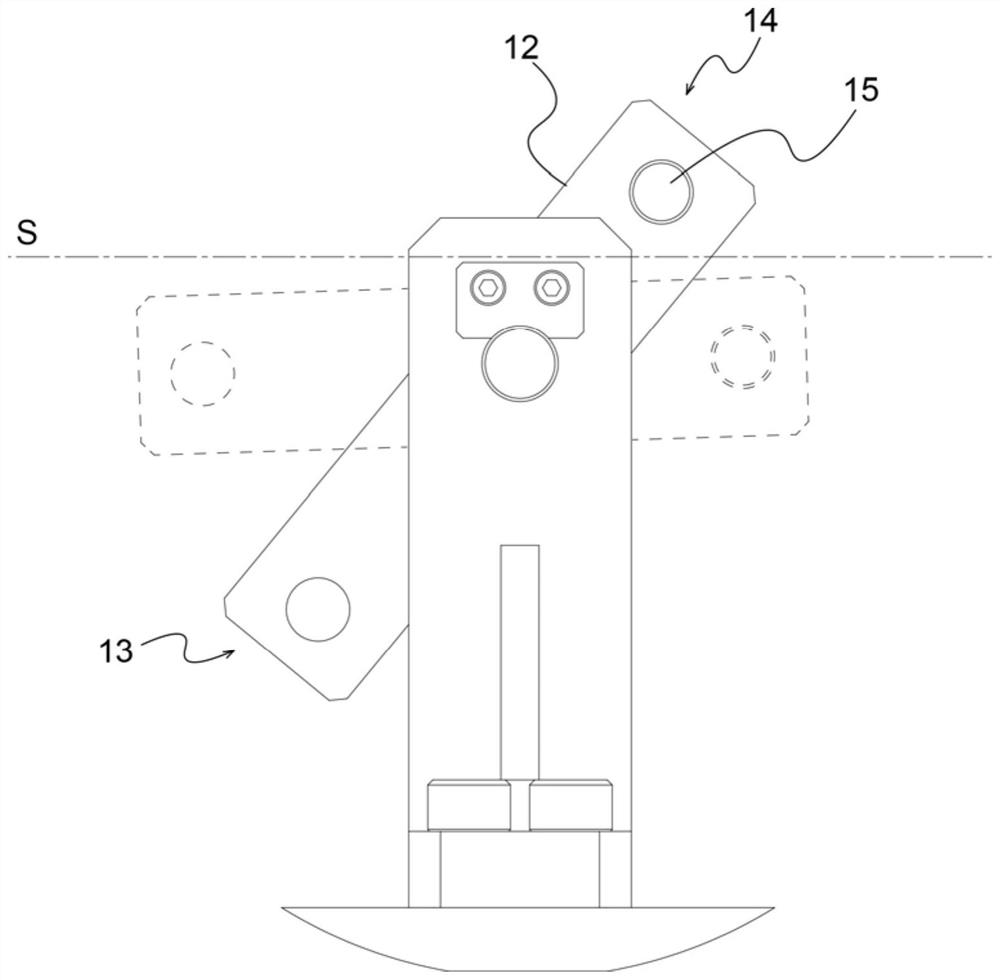

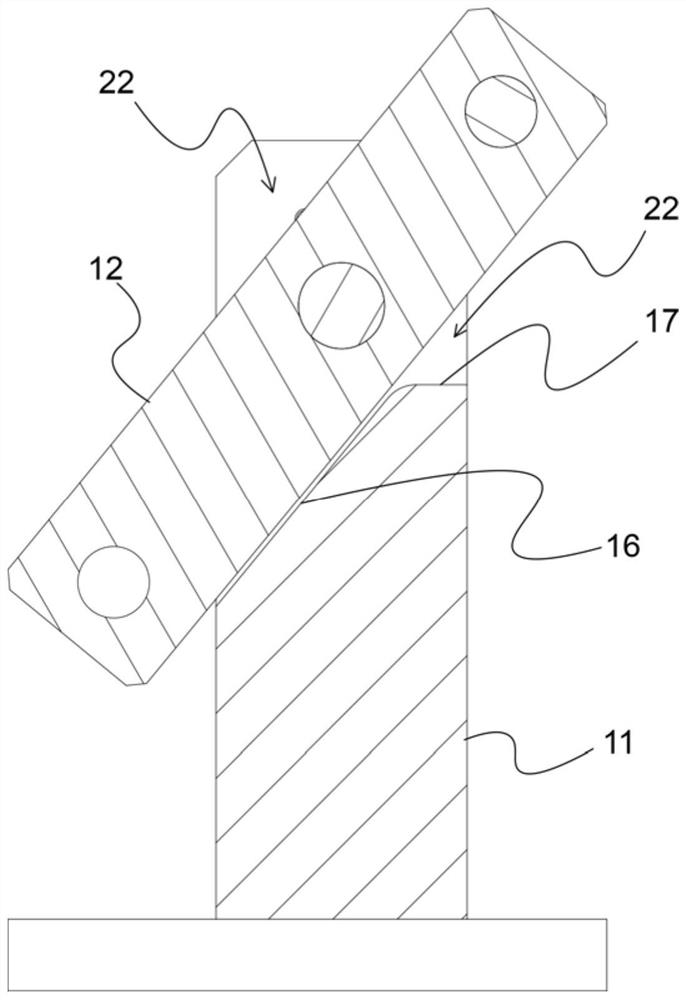

Material conveying roller bed and stop mechanism thereof

InactiveCN111776716ANot easy to fallPlay a stop roleConveyor partsRoller-waysIndustrial engineeringHinge point

The invention relates to the field of material conveying, and discloses a stop mechanism for a material conveying roller bed and the material conveying roller bed comprising the stop mechanism. The stop mechanism comprises a transverse underframe, a vertical support and a stopper. The transverse underframe is fixedly arranged at an opening part of the material conveying roller bed; the vertical support is fixedly arranged on the transverse underframe and extends upwards on the outer side of the opening part of the material conveying roller bed; and the stopper is hinged to the vertical supportabout a central axis parallel to the conveying direction of the material conveying roller bed, and a hinge point of the stopper and the vertical support deviates from the center of gravity of the stopper, wherein the heavier end and / or the lighter end of the stopper are / is provided with an actuating member protruding outwards. According to the technical scheme, by utilizing the stop mechanism, materials can be prevented from falling in the conveying process of the conveying roller bed, so that the safety and the reliability of the material conveying roller bed are improved.

Owner:南京宇众自动化装备有限公司

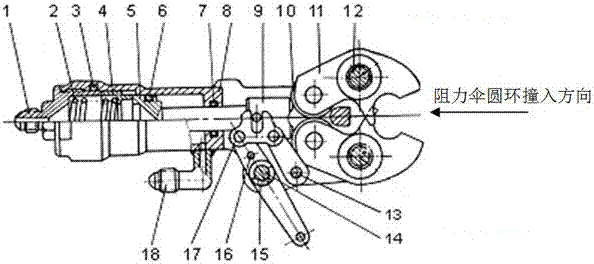

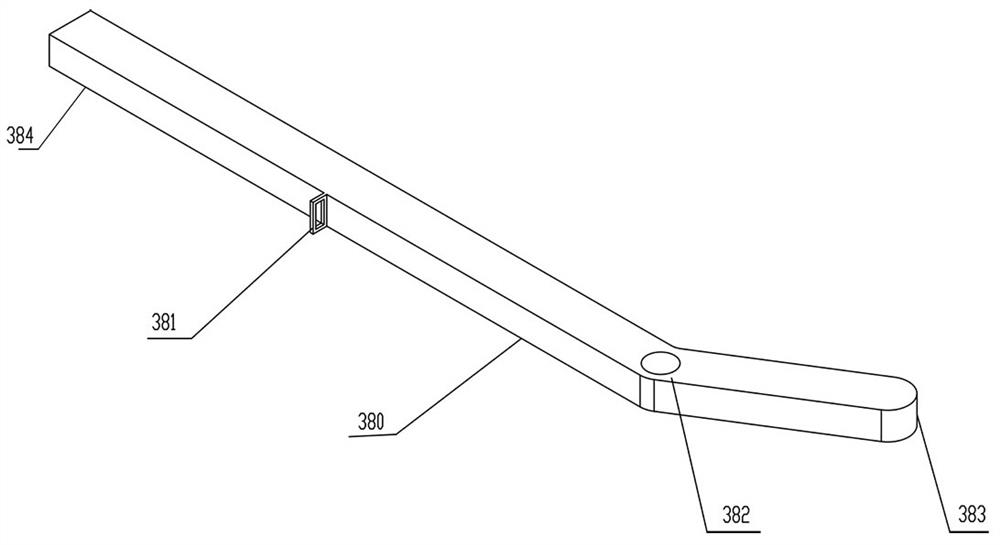

Drag parachute lock hook device

The invention relates to the field of aircrafts and particularly relates to a drag parachute lock hook device capable of ensuring the safety of an aircraft in the stages of takeoff, flight and landing. The drag parachute lock hook device comprises a locking inlet nozzle and an unlocking inlet nozzle, wherein the locking inlet nozzle is connected with a compression spring; the compression spring is connected with a stop bushing; a piston is arranged beside the stop bushing; a slide block is fixed on the piston; the slide block is connected with a roller, and one end of the slide block is butted to the roller of a hook body; the hook body comprises two shifting claws which are oppositely arranged, and each shifting claw is provided with a rotating shaft; the hook body is also connected with a shifting fork rocker arm group; one end of the shifting fork rocker arm group is connected with the unlocking inlet nozzle, and the other end of the shifting fork rocker arm group is connected with a roller latch mechanism; the roller latch mechanism is connected with a bulge; the bulge is connected with a rocker arm mounting shaft; and the rocker arm mounting shaft is connected with the shifting fork rocker arm group. The lock hook with an error prevention function avoids the harm of serious accidents caused by accidental parachute deployment, so that the system failure rate is greatly reduced, and the system reliability is greatly enhanced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

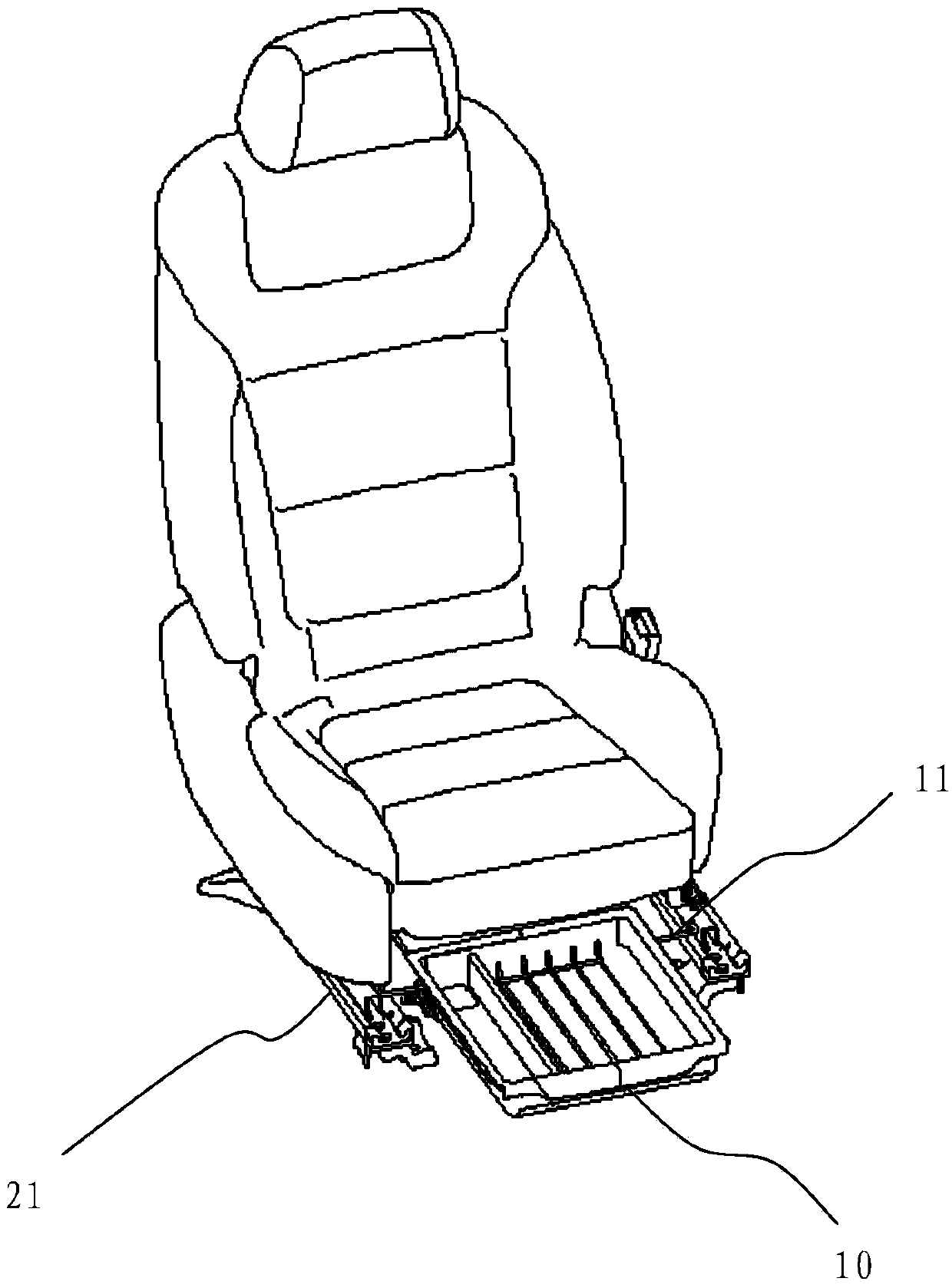

A car seat storage box device

ActiveCN103738249BMeet the convenience of storage at the same timeReduce frequencyPassenger spaceRacks dispositionInterior spaceCar seat

The invention discloses an automobile seat storage box device comprising a storage box body. Two sides of the storage box body are provided with two guide channels respectively; the guide channels are slidably disposed on two guide rails respectively; the guide rails are fixed on a seat slide rail below an automobile seat. The front end of each guide rail is provided with a limit part. The side, corresponding to the limit part, of the storage box body is provided with a lock handle. The first end of the locking handle is provided with a push part, and the second end of the locking handle is provided with a holding part used for holding against the limit part. One side of the storage box body is provided with a limit post. A spring driving the push part to hold against the limit post is arranged between the locking handle and the storage box body. The storage box body is disposed below the automobile seat, requires small excess interior space of an automobile and is convenient to operate, demount and clean, and frequency of using plastic tapes to place trash is greatly reduced.

Owner:YANFENG ADIENT SEATING CO LTD

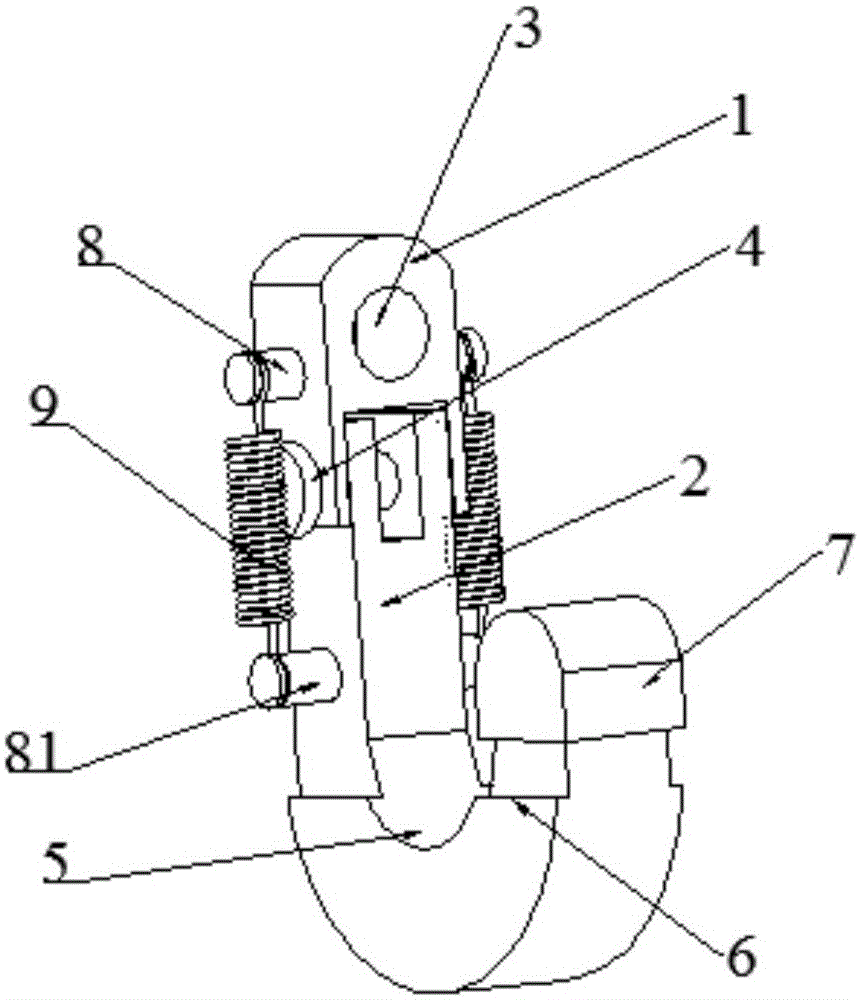

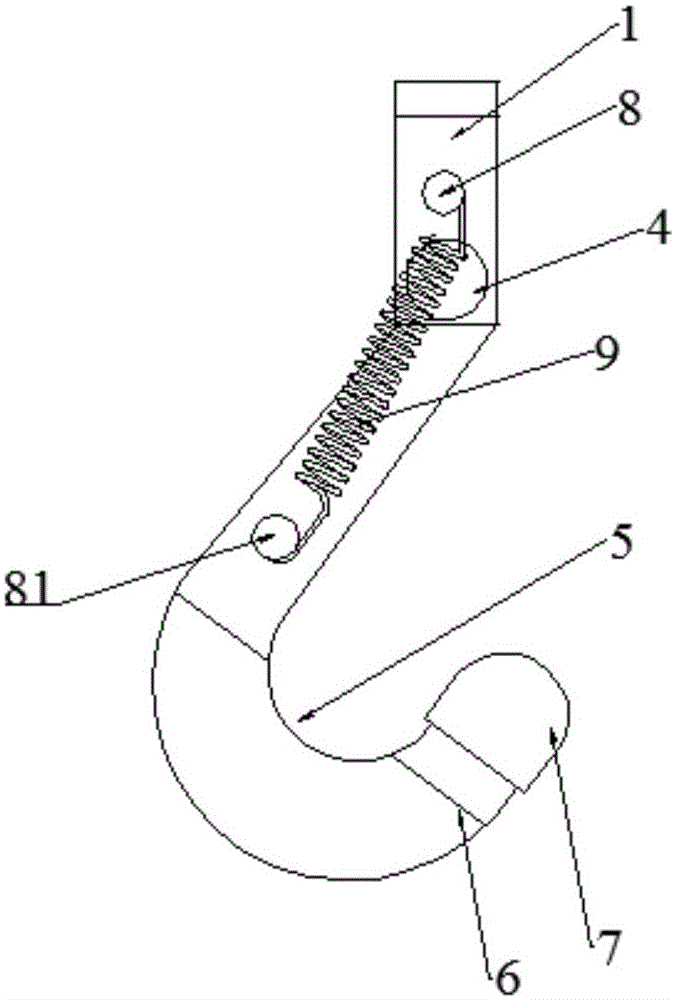

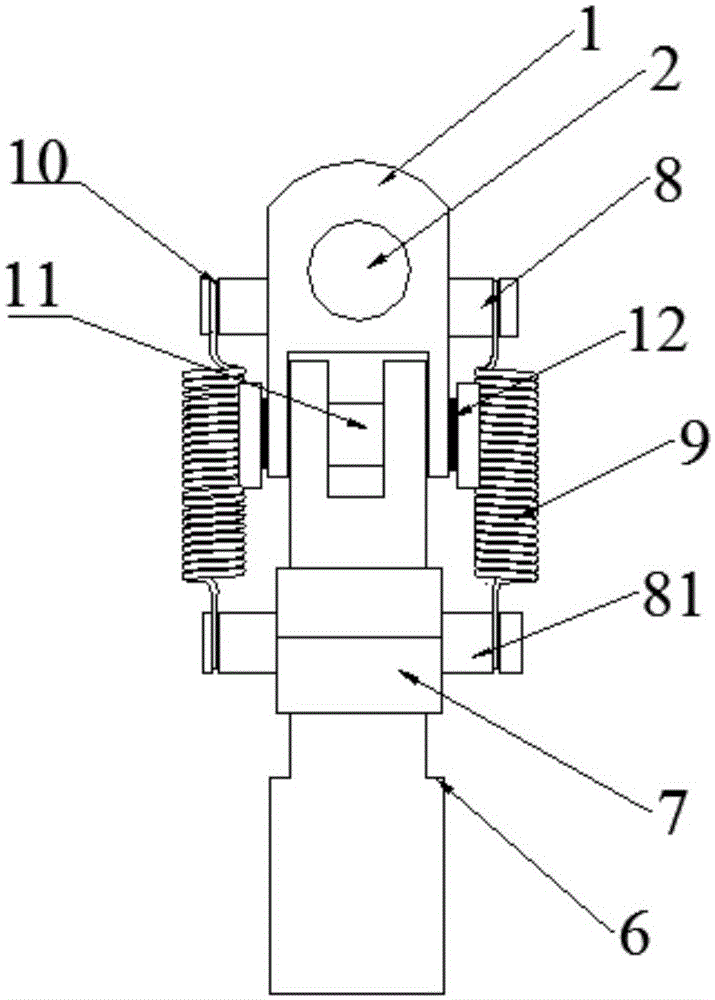

Cast-molded lifting hook

InactiveCN106276581APlay a buffer rolePrevent throwingLoad-engaging elementsCasting moldIndustrial engineering

The invention provides a cast-molded lifting hook. The lifting hook comprises a lifting ring, a connecting hole in the middle of the lifting ring, a hook part hinged to the lifting ring and a bearing hole formed in the central axis direction of the hook part; the lifting hook is characterized in that upper fixing shafts are arranged on two sides of the lifting ring; lower fixing shafts are arranged on two sides, close to the lifting ring, of the hook part; spring pieces are connected between the upper fixing shafts and the lower fixing shafts; reinforcing bodies are arranged on two sides of the bottom of the hook part and surround the central axis of the bearing hole; and a bulge body is arranged at the tail of the hook part. According to the lifting hook, elastic pieces are arranged between the lifting ring and the hook part and have a buffering effect, and the condition that a carried object is thrown out due to excessively large swing amplitude of the hook part in the running process is avoided; the position of the bearing hole is reinforced, and breakage under the relatively large stress is avoided; and the bulge body is added to the tail of the hook part and has a stop effect, and the potential safety hazard caused by the fact that the object slides along the bearing hole in the conveyed process and separates from the lifting hook is avoided.

Owner:TIANJIN YUXINGDA CASTING IND CO LTD

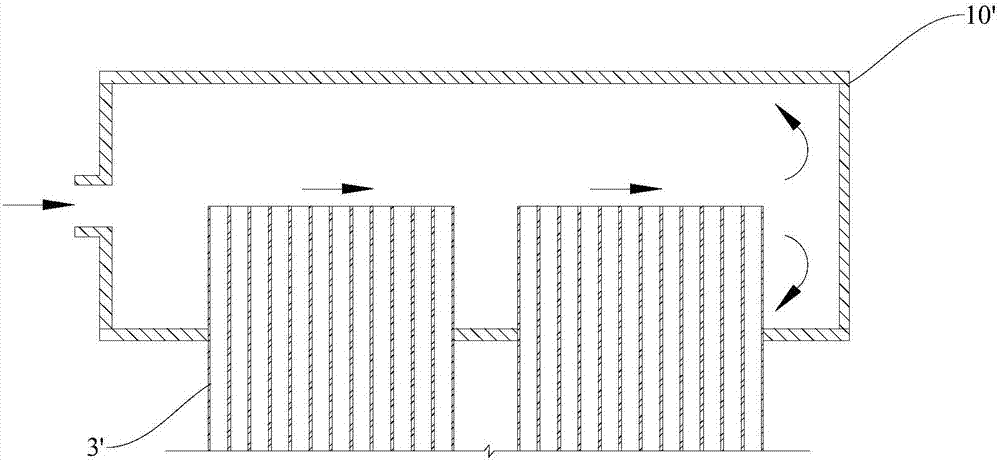

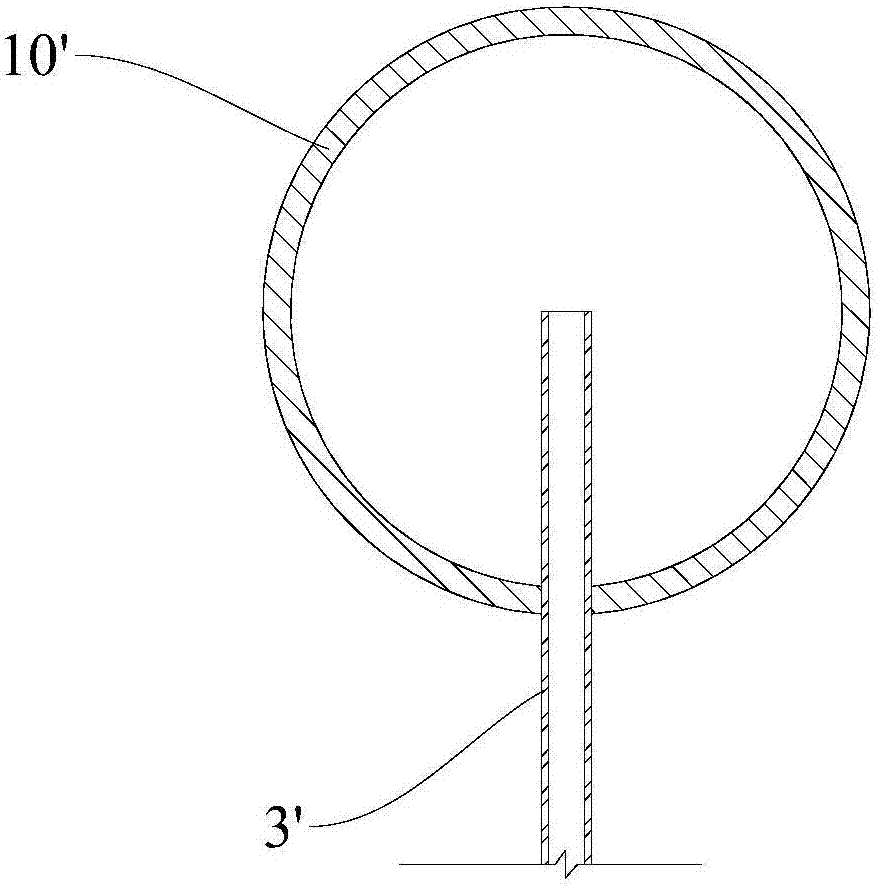

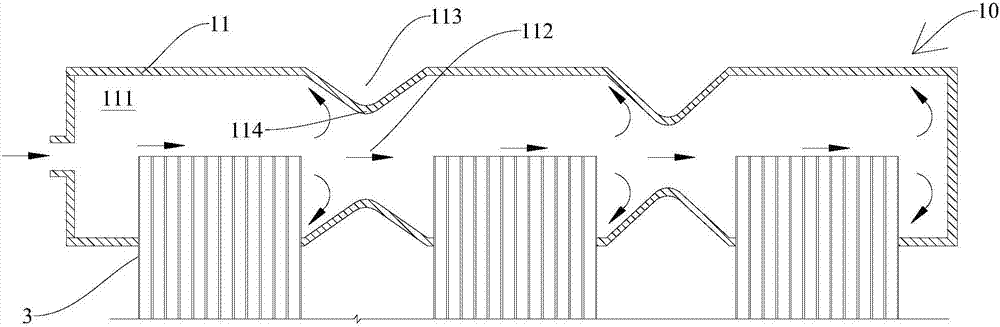

Collecting pipe and heat exchanger with same

InactiveCN107543336AReduce poolingImprove heat transfer effectEvaporators/condensersHeat exchanger casingsRefrigerantEngineering

The invention discloses a collecting pipe and a heat exchanger with the collecting pipe. The collecting pipe comprises a pipe body, a refrigerant cavity is formed inside the pipe body, the pipe wall of the pipe body is provided with multiple flat pipe grooves formed in the axial direction of the pipe body at intervals, a throttling portion is arranged between every two adjacent flat pipe grooves and located in the refrigerant cavity, and the cross sectional area of each throttling portion is smaller than that of the other part of the refrigerant cavity. According to the collecting pipe in theembodiment, refrigerants flowing into flat pipes tend to be uniform, and then the heat exchange effect of the heat exchanger is improved.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

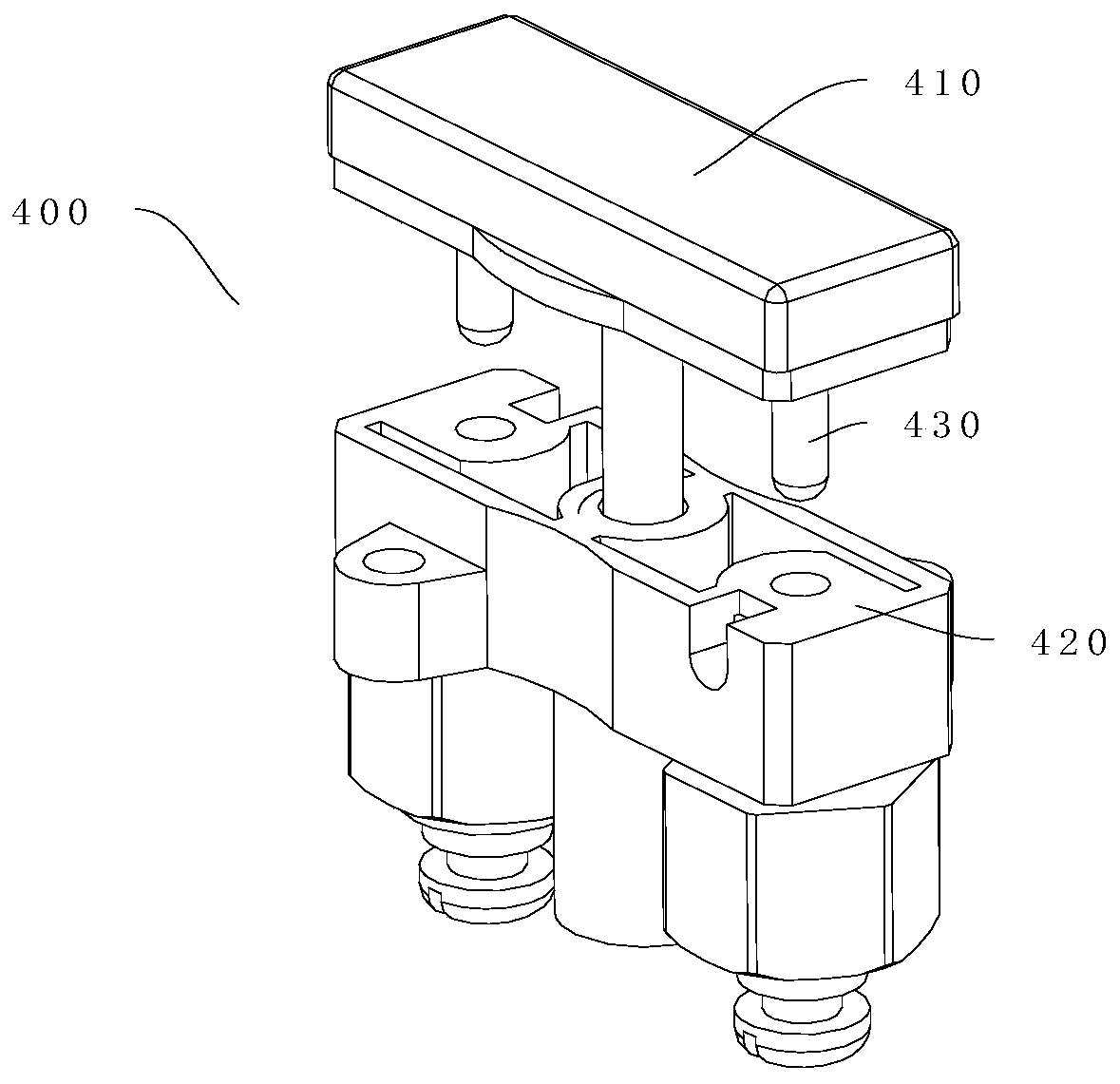

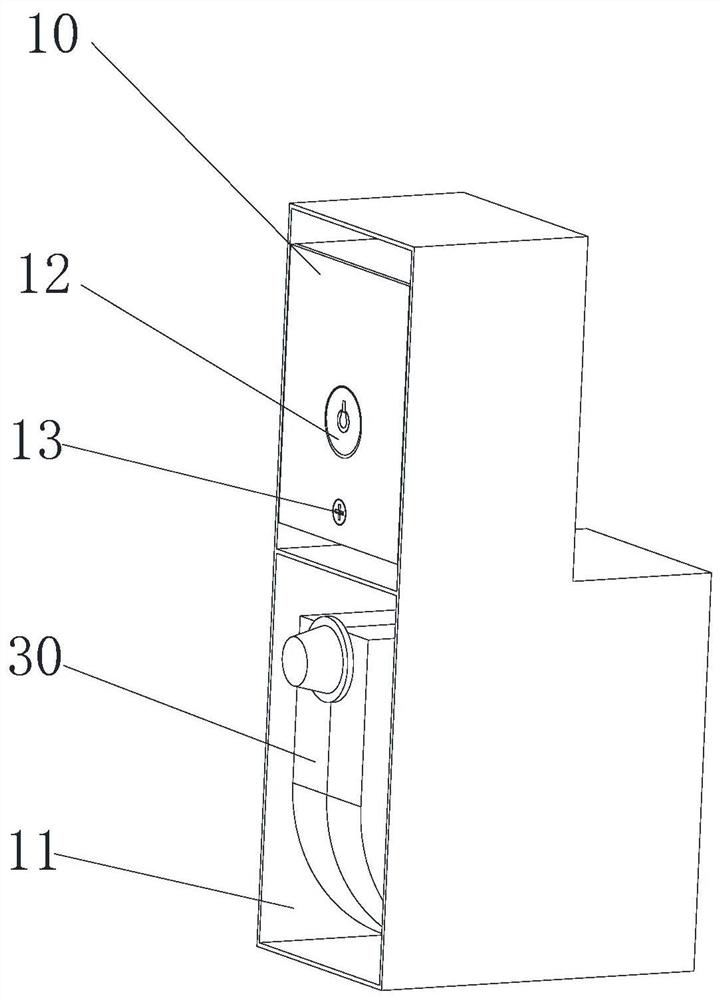

Pressure plate locking device

PendingCN109728506AImplement mandatory lockingPlay a stop roleSubstation/switching arrangement boards/panels/desksEngineeringMechanical engineering

The invention provides a pressure plate locking device. The pressure plate locking device comprises: a housing, wherein a part of the housing is taken as a positioning holding portion and has a handleholding cavity for accommodating a pressure plate handle, when the positioning holding portion is located between the pressure plate handle and a pressure plate base, a plug of the pressure plate handle is in a state of separation from the conductive jack of the pressure plate base; a protruding structure having a protruding position and a retracted position relative to the housing, wherein whenthe pressure plate handle is in the handle holding cavity, the pressure plate handle can be locked with the positioning holding portion; and a lock body module configured to lock the protruding structure, wherein the lock body module is arranged in the lock body holding cavity of the housing, and has a lock state and an unlock state, when the lock body module is located in the locking state, the lock body module locks the protruding structure, and when the lock body module is in the unlock state, the lock body module unlocks the protruding structure. The problem of the safety hazard of the erroneous operation of the power wiring device is solved in the prior art.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

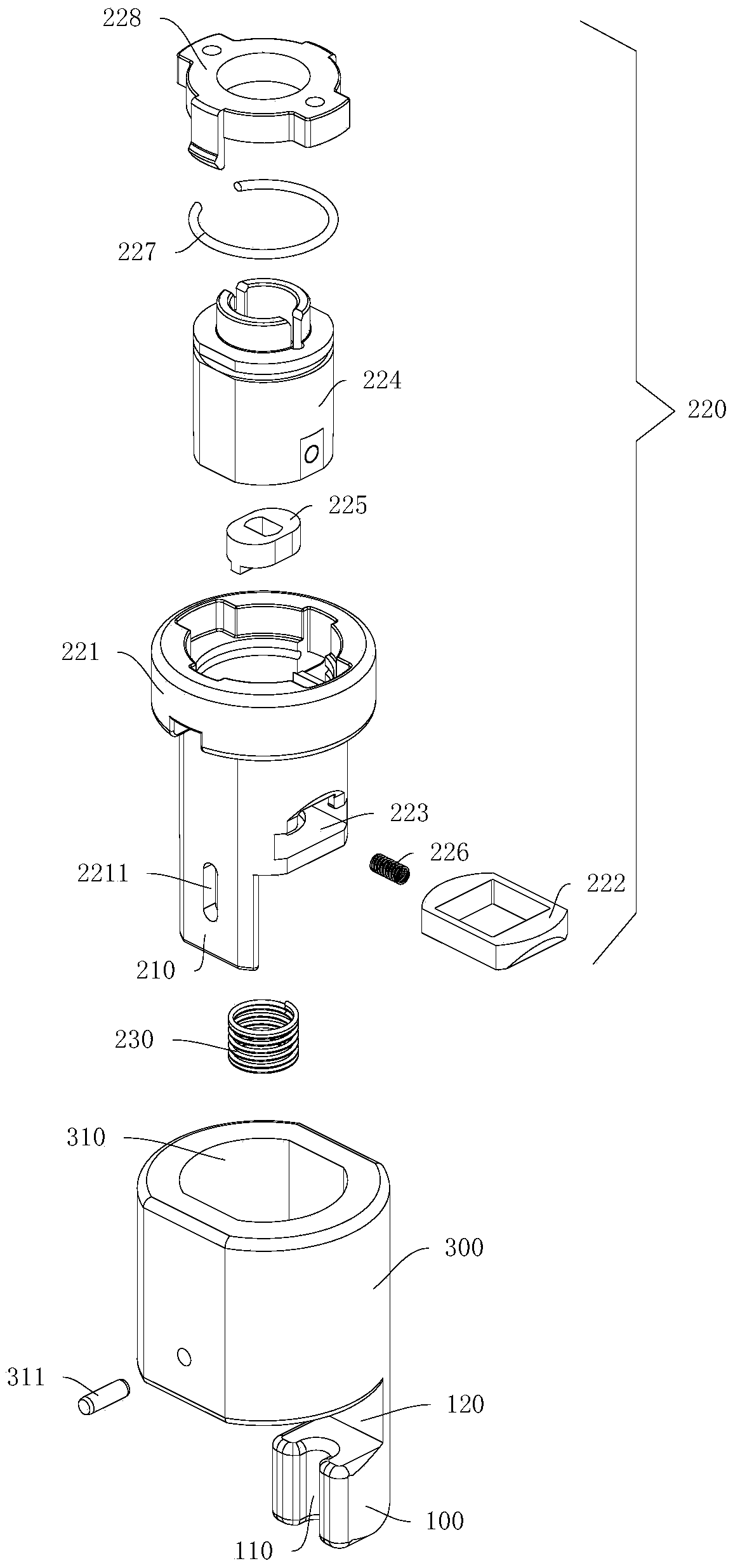

Nut taking device and nut driving equipment

PendingCN112935778APlay a stop roleImprove operational efficiencyMetal working apparatusEngineeringMechanical engineering

The invention provides a nut taking device and nut driving equipment. The nut taking device comprises a taking assembly arranged movably, a first detection component and a scraping part, wherein the taking assembly comprises a taking connector, which is rotatably arranged to be sleeved with a nut; the first detection component has a detection position and is used for detecting whether the the taking connector is sleeved with the nut in a qualified mode or not by moving the nut sleeving the taking connector to the detection position; and the scraping part is provided with a scraping groove, and when it is judged that sleeving of the nut is unqualified, the taking connector is arranged in the scraping groove in a penetrating mode, the nut is located on one side of the scraping groove and abuts against the scraping part, and the taking connector moves towards the side, away from the nut, of the scraping groove, so that the nut is separated from the taking connector under the stop effect of the scraping part. According to the nut taking device, automatic nut picking work can be realized, so that the efficiency of nut driving operation is improved, and the problem that in the prior art, the production efficiency of nut driving operation on a compressor is low can be solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

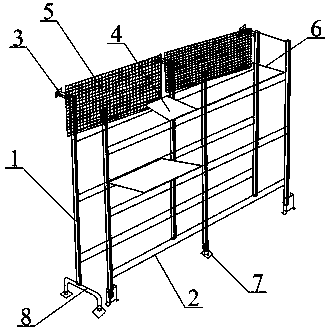

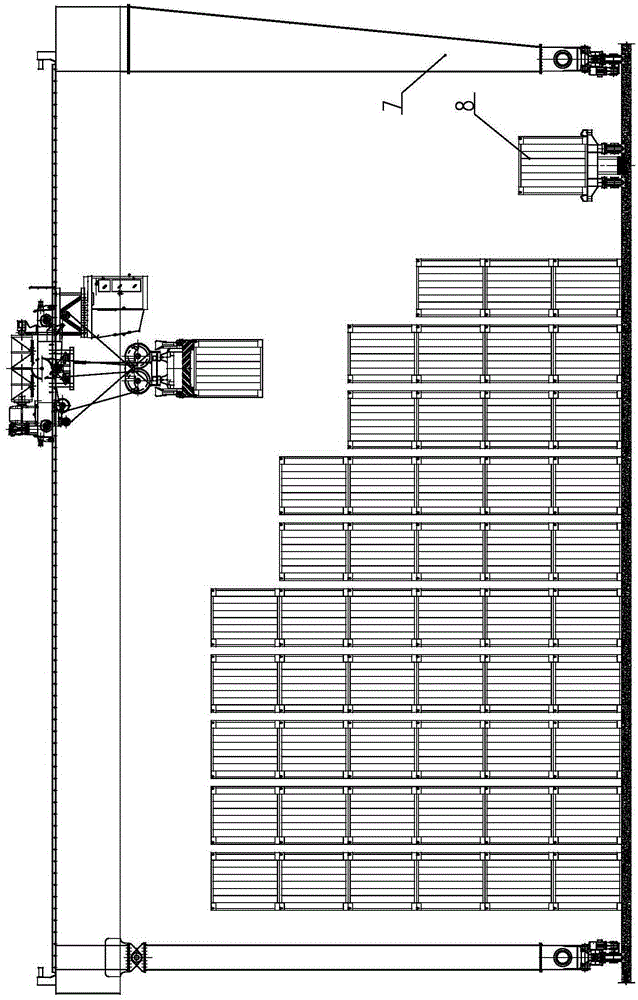

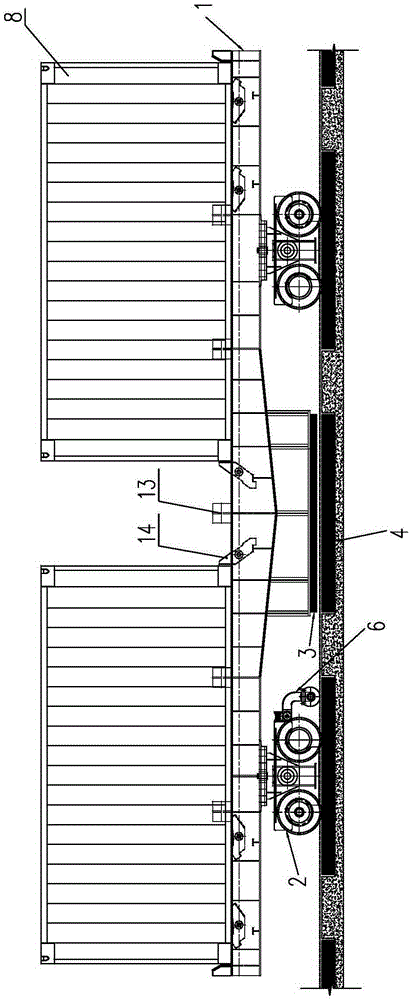

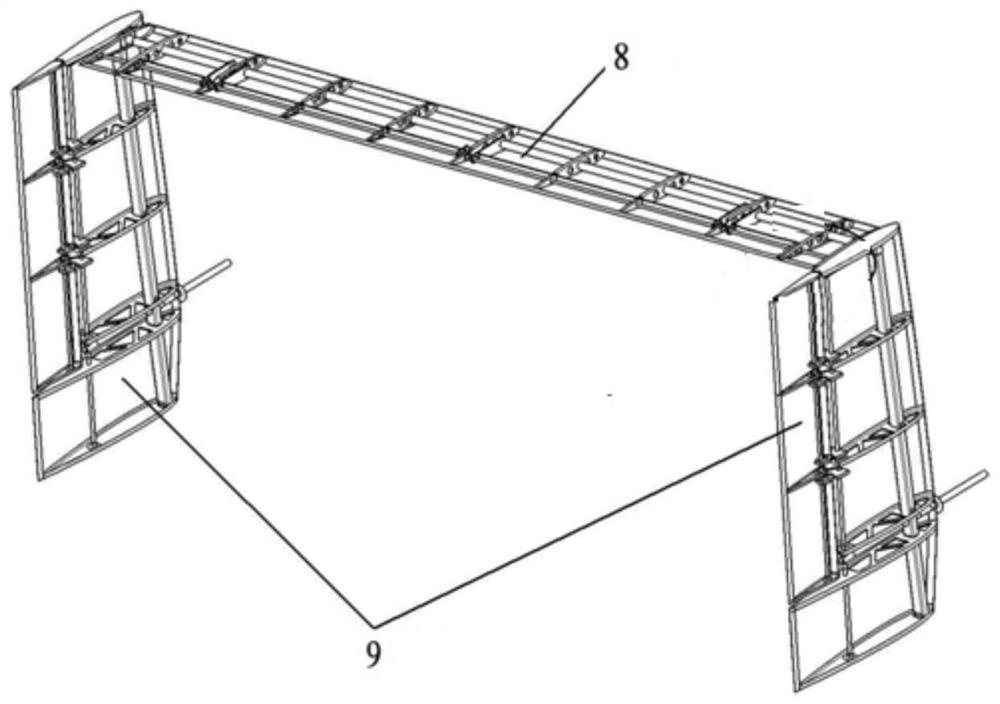

Goods allocation type storage rack for novel multifunctional automatic stereoscopic warehouse

InactiveCN106276002AReduce manufacturing costSave resourcesStorage devicesEngineeringInverted-T shape

The invention provides a goods allocation type storage rack for a novel multifunctional automatic stereoscopic warehouse. The good allocation type storage rack comprises stand columns, cross beam devices, wall supports, movable devices, a back net, a cross support, protection legs and guiderails. The cross beam devices are perpendicularly connected with the stand columns; the wall supports are fixedly connected to the back parts of the stand columns; the movable devices are arranged on the upper parts of the two cross beam devices; the back net is connected between the two wall supports; the cross support is fixedly connected between the two stand columns; the protection legs are arranged on the front and back sides of the lower parts of the stand columns; and the guiderails are arranged on the left and right sides of the lower parts of the stand columns. With the arrangements of the cross beam rack, connection holes, brake plates and the protection legs, the stand columns can be protected by the protection legs, so service life of the storage rack can be prolonged; an inverted T shape can brake rolling wheels, so movements of the storage rack can be controlled and the storage rack can bear enough weight and manufacturing cost can be reduced; and resource can be reduced; and stable cross beam connection can be guaranteed and potential safety danger can be reduced.

Owner:天津音飞自动化仓储设备有限公司

Door structure of special railway vehicle

ActiveCN105221012AEfficient loadingSolve the problem of non-uniform door gapsWing fastenersSealing arrangementsLocking mechanismCar door

Owner:CRRC QINGDAO SIFANG CO LTD

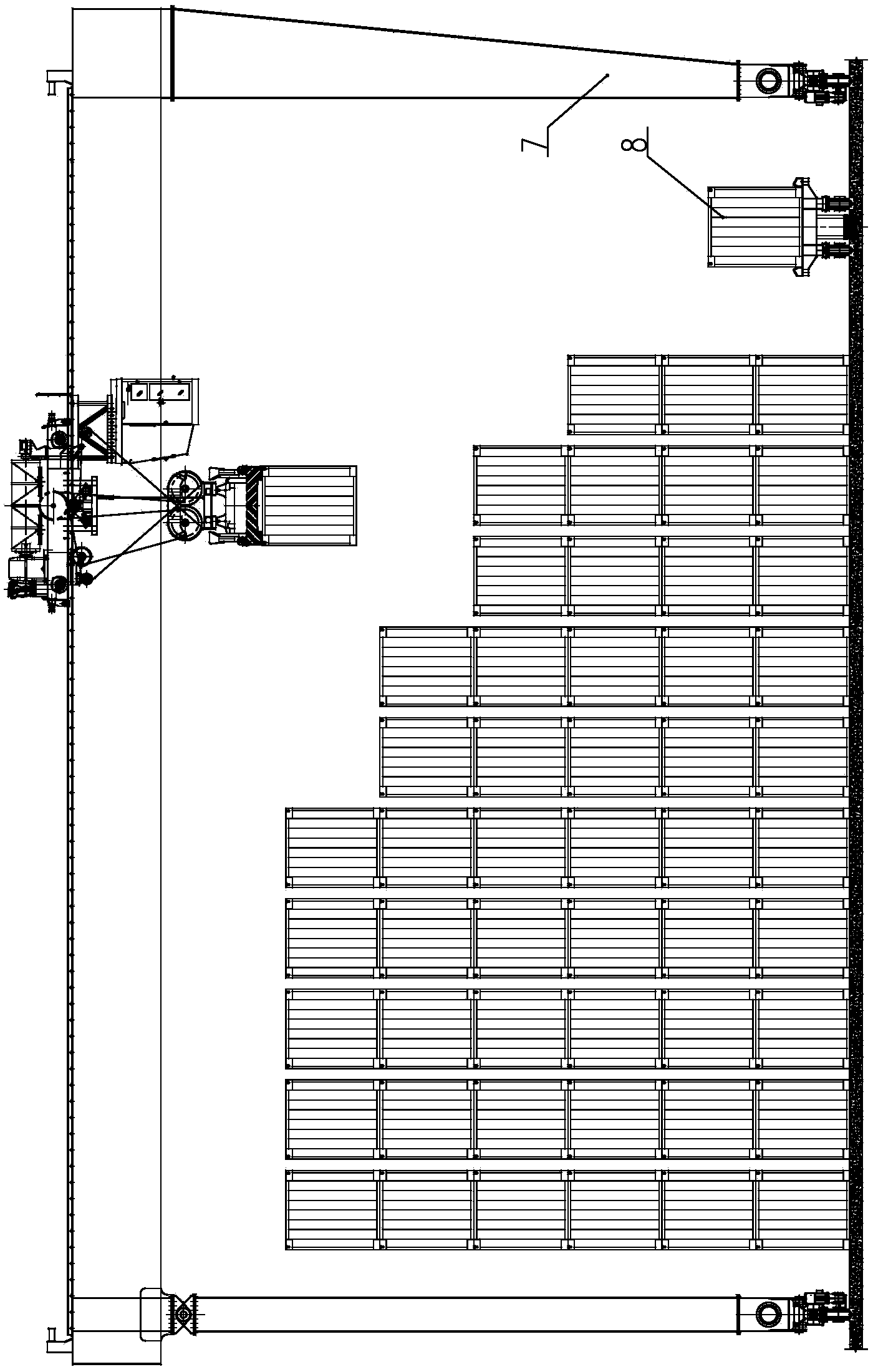

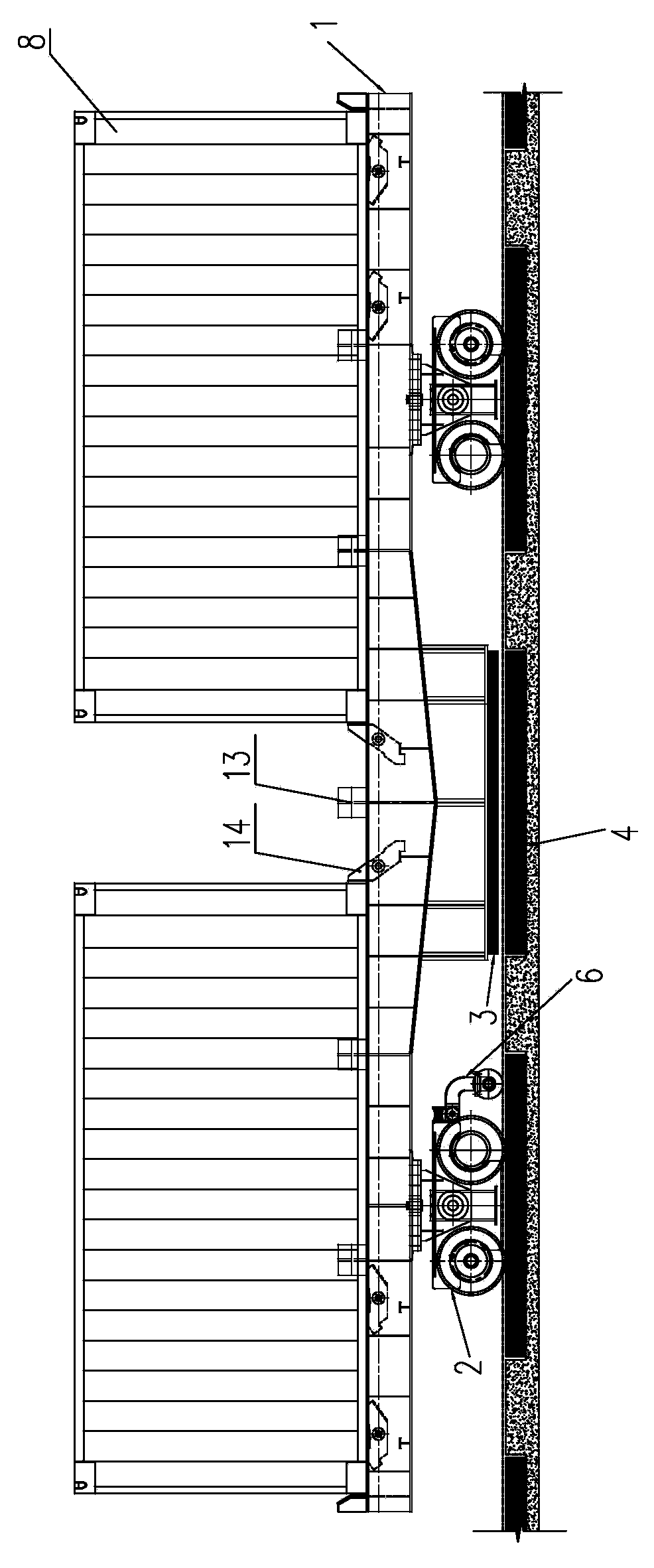

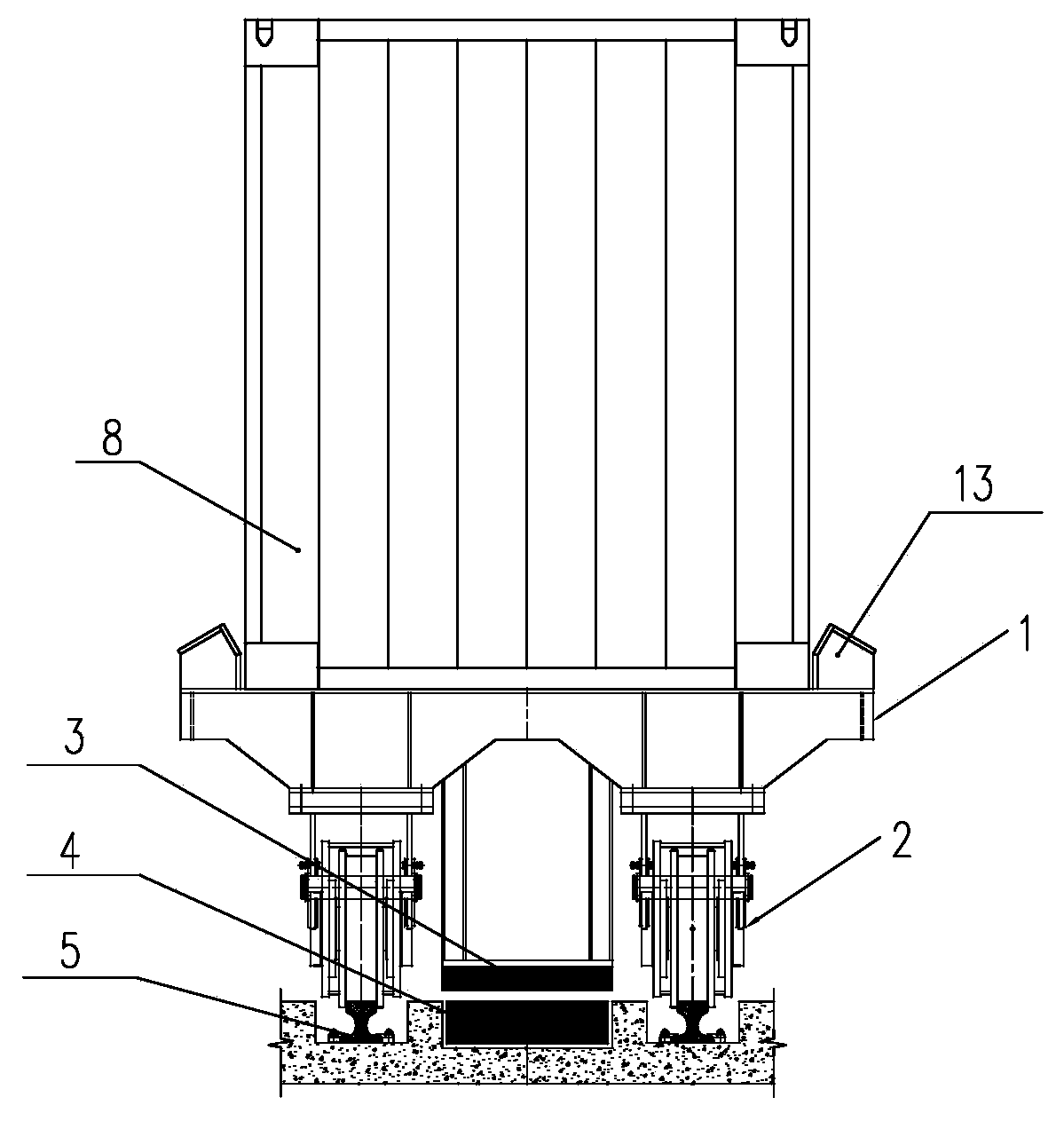

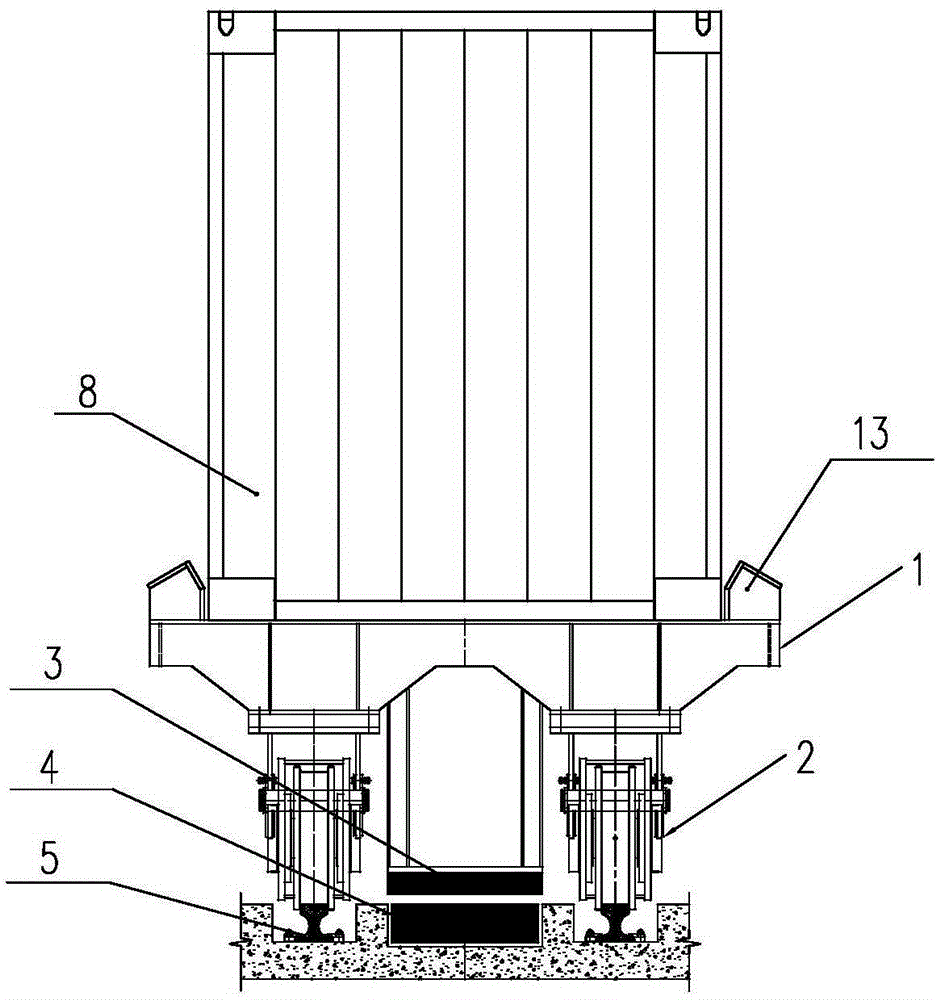

Magnetomotive container transfer vehicle

ActiveCN104229409AImprove applicabilityAvoid problems with cross work areasWagons/vansCargo supporting/securing componentsMagnetic energyConductor Coil

The invention discloses a magnetomotive container transfer vehicle. The magnetomotive container transfer vehicle comprises a vehicle body, wheel sets, a permanent magnet, a plurality of drive windings, tracks and a calibrated wheel set, wherein the drive windings are arranged on the ground, the permanent magnet is arranged at the lower part of the vehicle body, the drive windings are used for converting electric energy into magnetic energy to interact with the permanent magnet, and the container transfer vehicle is pushed to run; the calibrated wheel set is mounted on at least one of the wheel sets, the calibrated wheel set is provided with an encoder for detecting the running speed and distance of the container transfer vehicle, the calibrated wheel set is used for stably pressing calibrated wheels on the tracks on the ground depending on the effect of a pressure spring, so that accurate running speed and distance detected by the encoder are guaranteed; the vehicle body comprises cross beams and longitudinal beams, the upper parts of the two ends of the longitudinal beams are welded with fixed baffle plates, a plurality of movable baffle plates are arranged in the length direction of the cross beams, and the fixed baffle plates and the movable baffle plates play a role in stopping containers. The magnetomotive container transfer vehicle is zero-pollution, zero-emission, high in degree of automation, high in work efficiency, low in comprehensive energy consumption and high in applicability.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

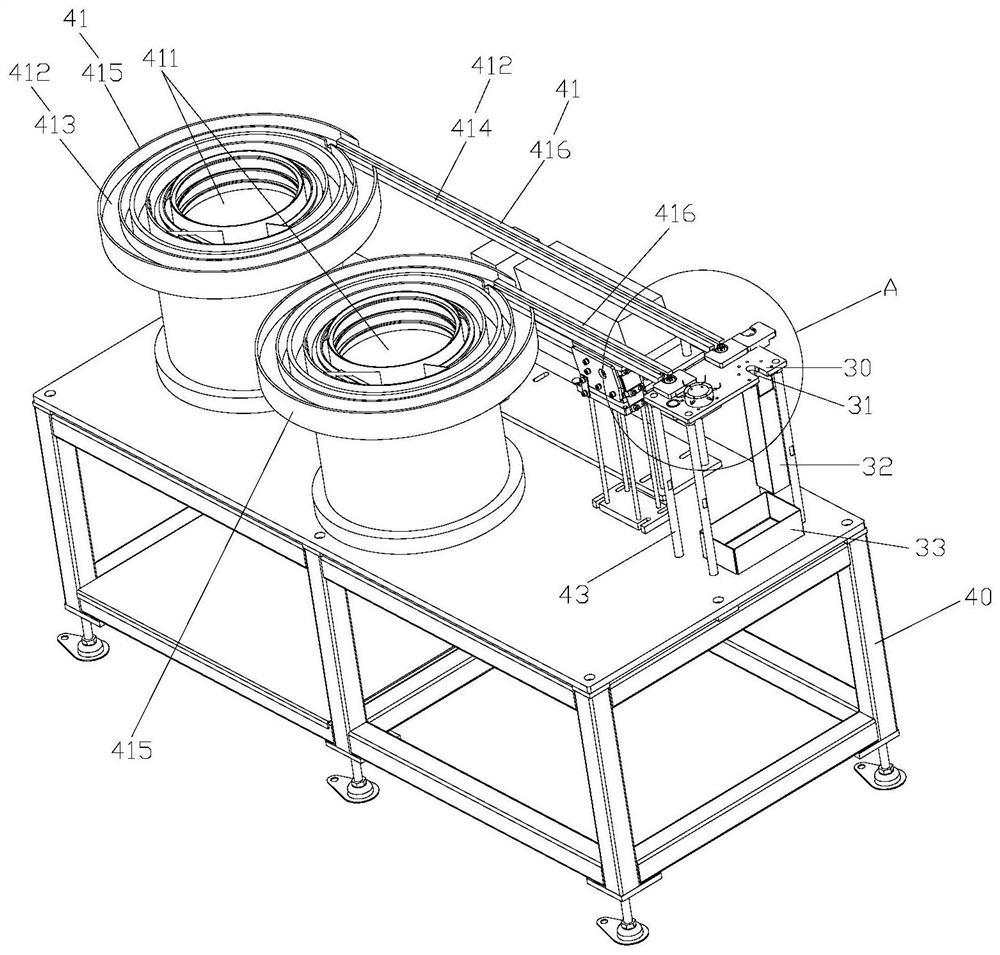

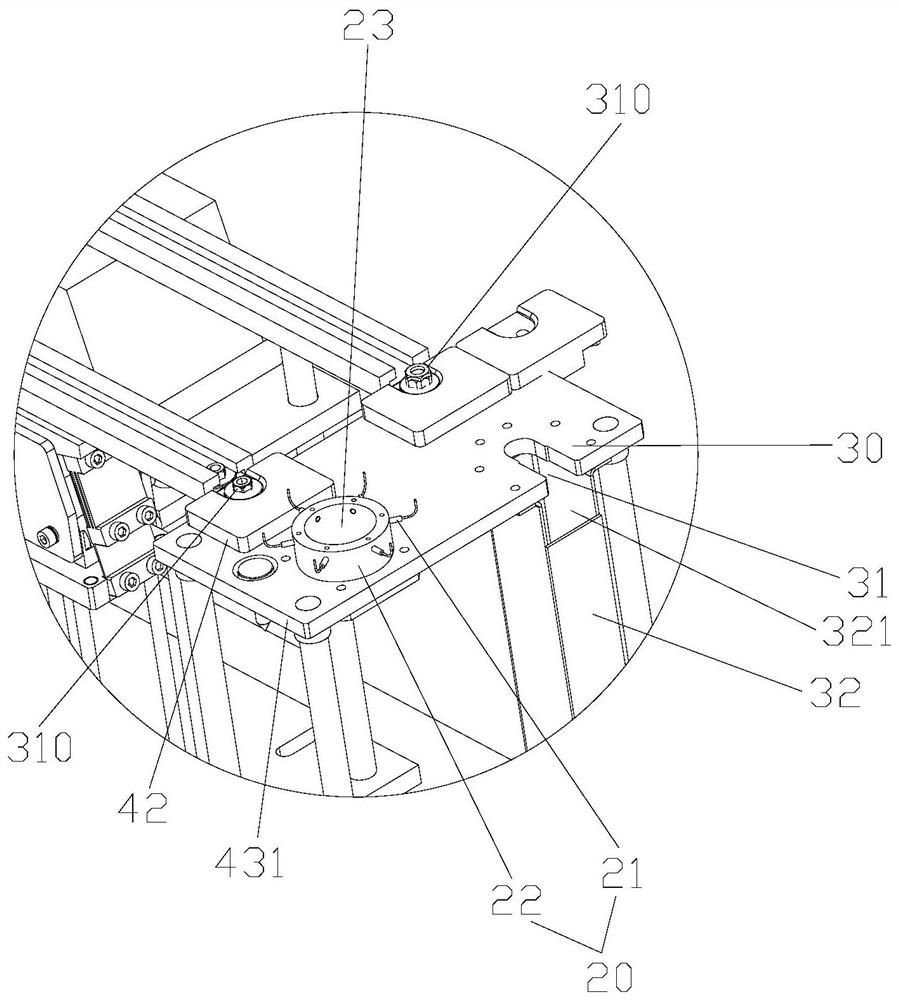

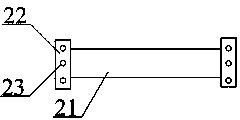

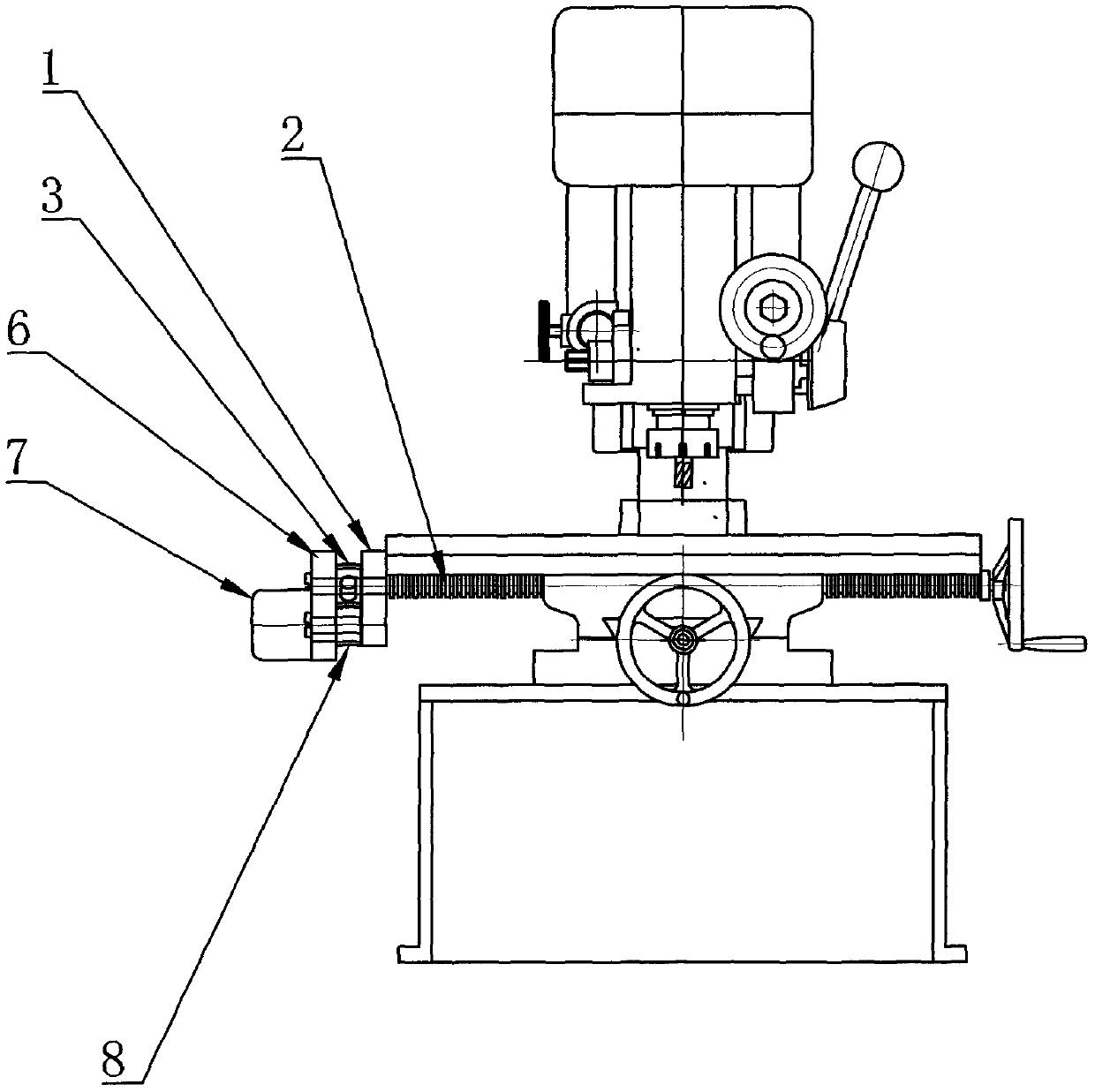

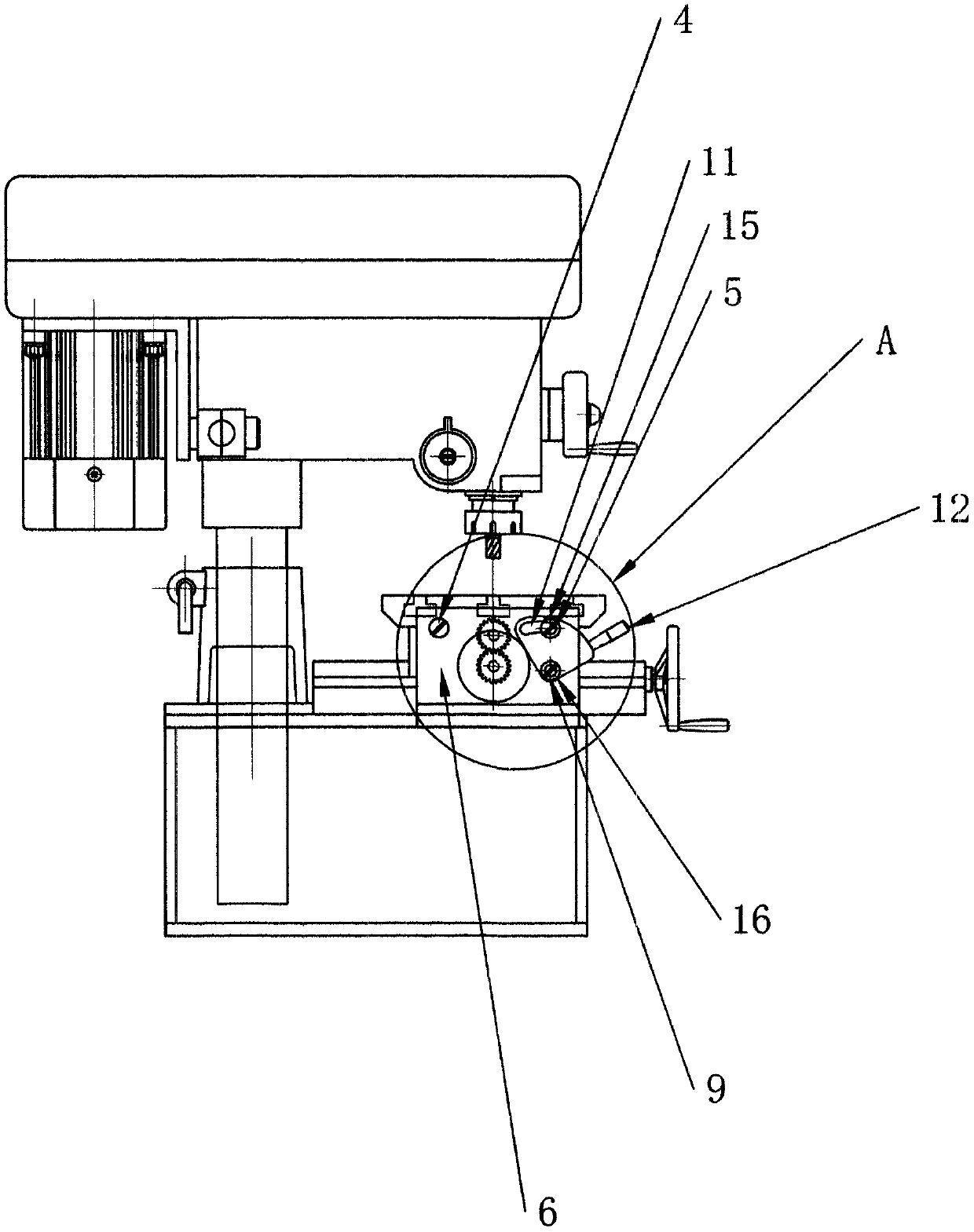

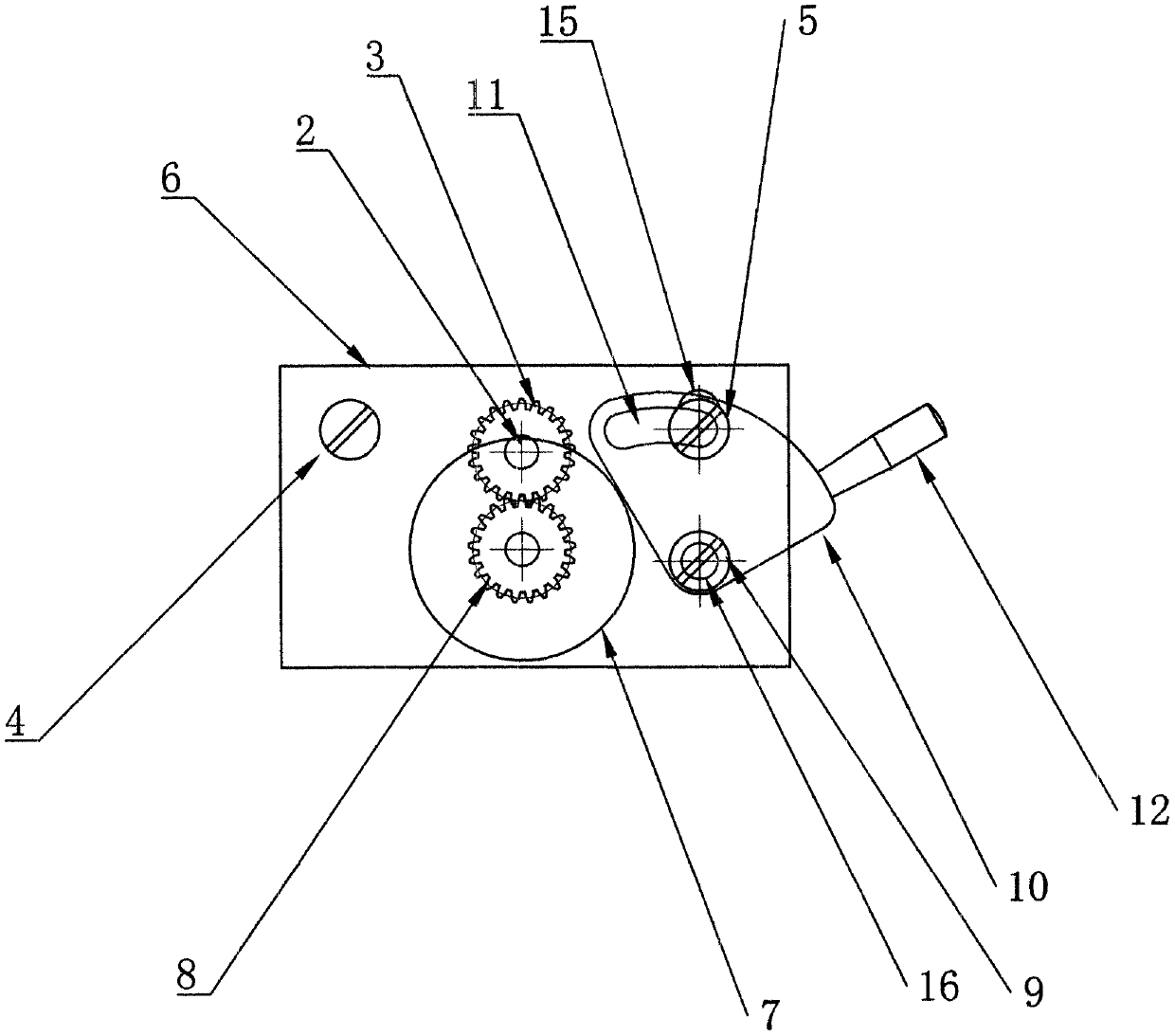

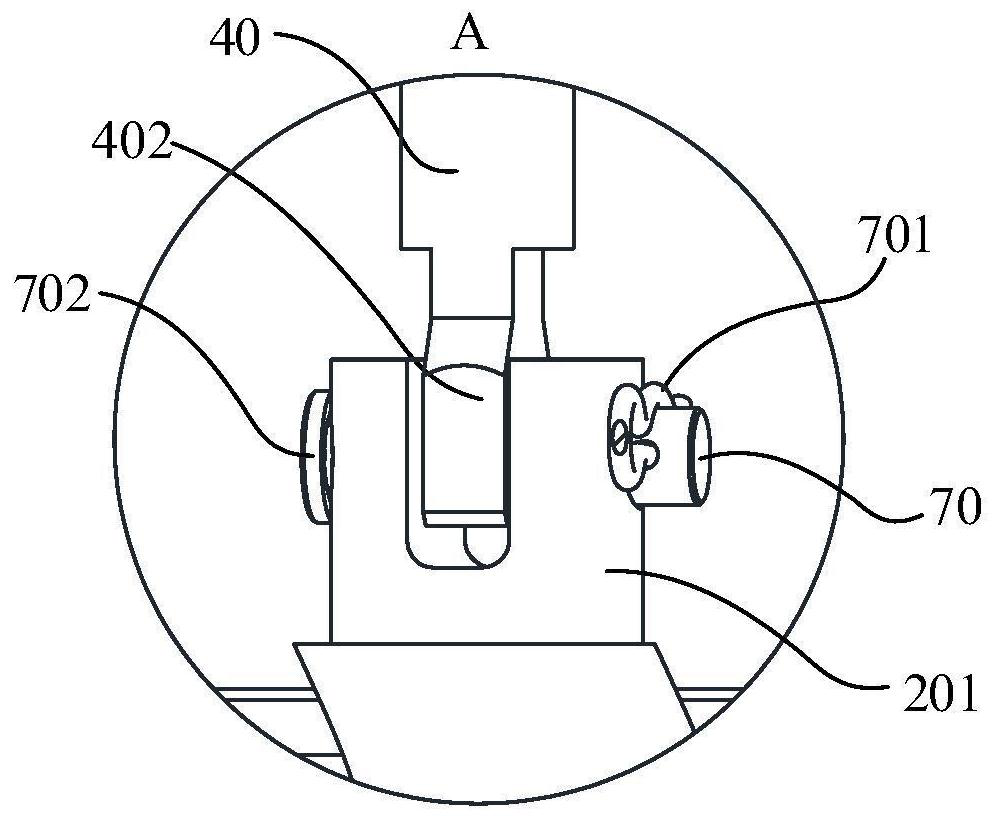

Automatic feeding mechanism and method for miniature machine tool

The invention relates to the field of machine tool machining and cutting, and more specifically relates to an automatic feeding mechanism and method for machining a miniature machine tool. The automatic feeding mechanism and method for the miniature machine tool aim at solving the problem that no effective and practical feeding mechanism is available on the market at present. The automatic feedingmechanism comprises a transition plate fixed on the miniature machine tool and a driven lead screw which is in threaded connection with the miniature machine tool and transversely penetrates throughthe transition plate, wherein the end part of the driven lead screw is provided with a driven gear, the transition plate is provided with a fixed hinge shaft and an upper hinge shaft, the transition plate is movably connected with a swing plate, the swing plate is provided with a fixed hinge shaft hole and a kidney-shaped groove hole, and the other side, which is opposite to the kidney-shaped groove hole, of the swing plate is provided with a lower hinge shaft. The automatic feeding mechanism further comprises a gear motor and the lower hinge shaft, wherein the output shaft end of the gear motor is provided with a driving gear located on the same plane with the driven gear, the lower hinge shaft is movably connected with a fan-shaped shifting block, the fan-shaped shifting block comprisesa lower hinge shaft hole and a fan-shaped groove, and the fan-shaped plate drives the swing plate through the fan-shaped groove to realize the engagement and disengagement of the driving gear and thedriven gear.

Owner:江苏一首机械科技有限公司

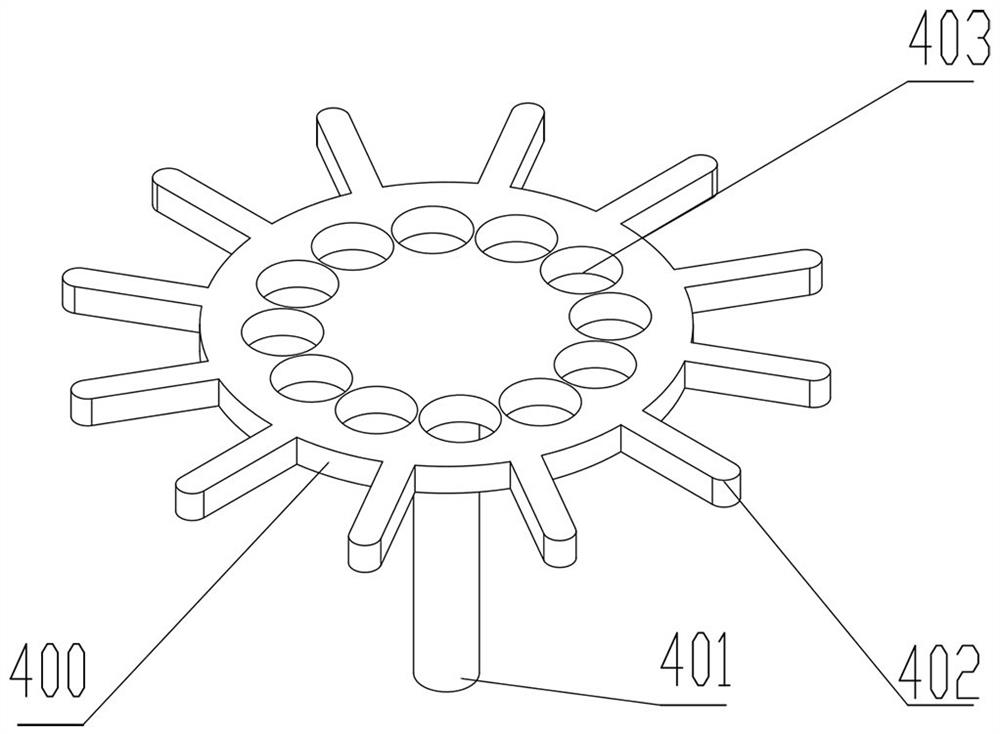

Tennis training ball serving device

The invention discloses a tennis training serving device which comprises a base, a middle plate rotating shaft is in the middle of the base, a first crankshaft hole is at the back side of the middle plate rotating shaft, a first eccentric shaft is at the upper part of a first crankshaft, a first rotating shaft is at the lower part of the first crankshaft, a bottom plate rotating hole is at the lower part of a middle plate, a first connecting rod shaft is at the back side of the bottom plate rotating hole, and a second crankshaft frame is at the upper part of the middle plate; the second crankshaft frame is provided with a second crankshaft hole, the front portion of the second crankshaft frame is provided with an upper plate frame, the upper portion of the upper plate frame is provided with an upper plate hole, a bottom plate rotating hole is rotationally connected with the middle plate rotating shaft, the bottom plate rotating hole rotates around the middle plate rotating shaft, the lower portion of the first rotating shaft is rotationally connected with the first crankshaft hole, and the first rotating shaft rotates in the first crankshaft hole. A second gear is fixedly connected to the upper part of the first rotating shaft, the first motor is fixedly connected with the base, an output shaft of the base is fixedly connected with a first gear, the first gear and the second gear are meshed with each other, and the rear side of a first connecting rod is rotationally connected with the first eccentric shaft.

Owner:HARBIN INST OF PHYSICAL EDUCATION

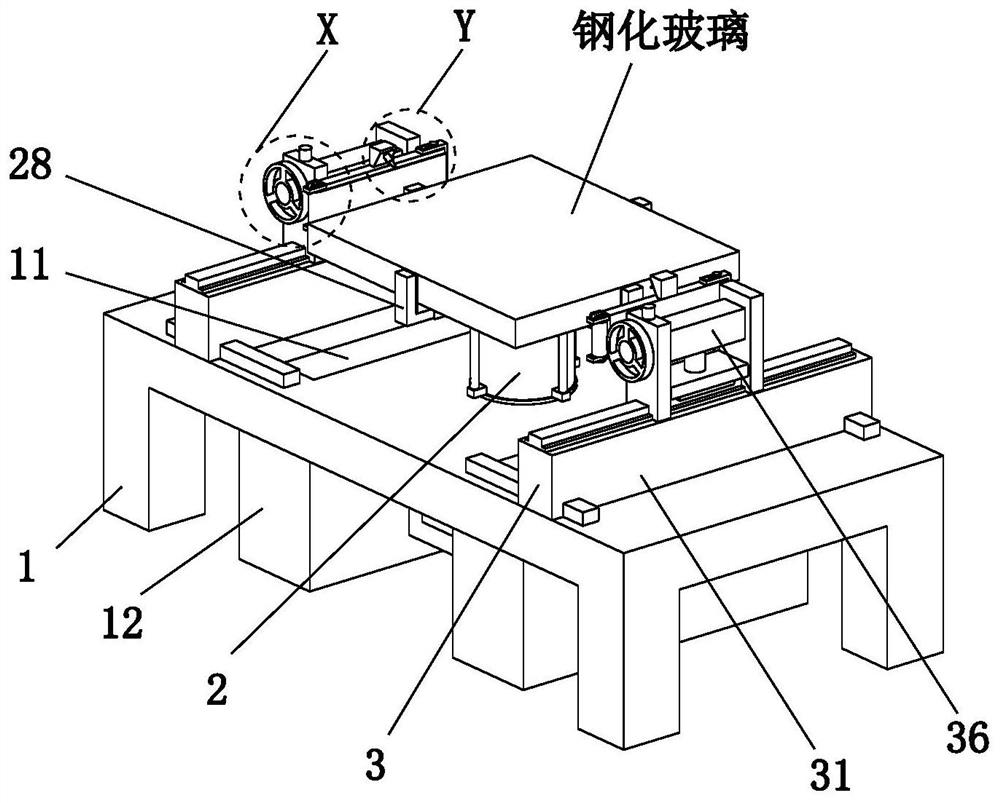

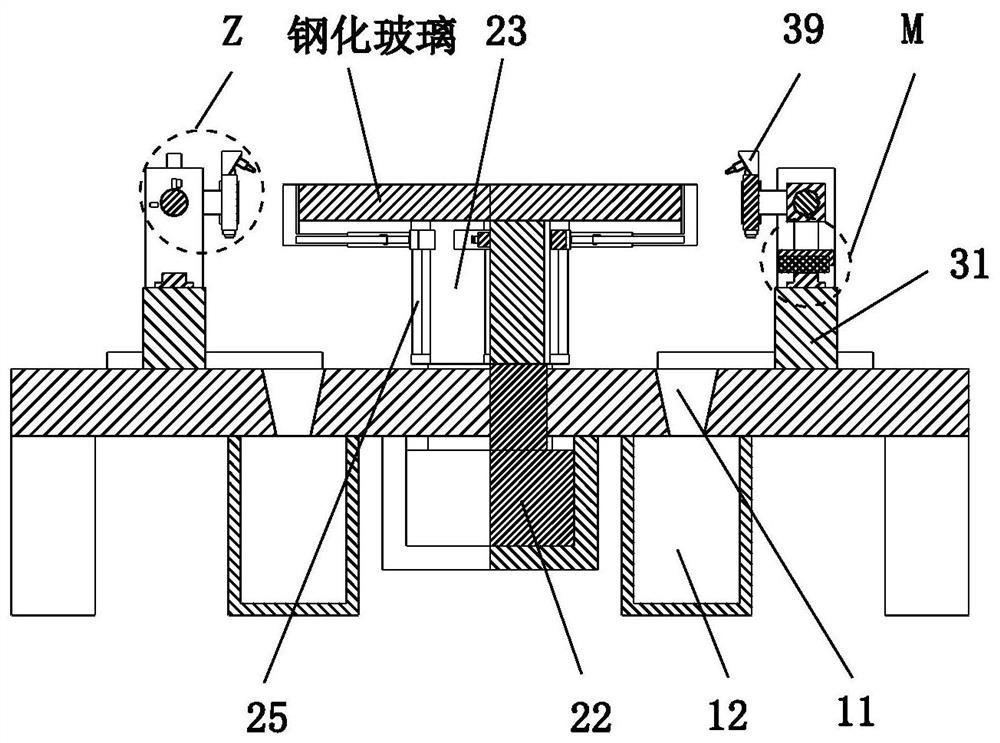

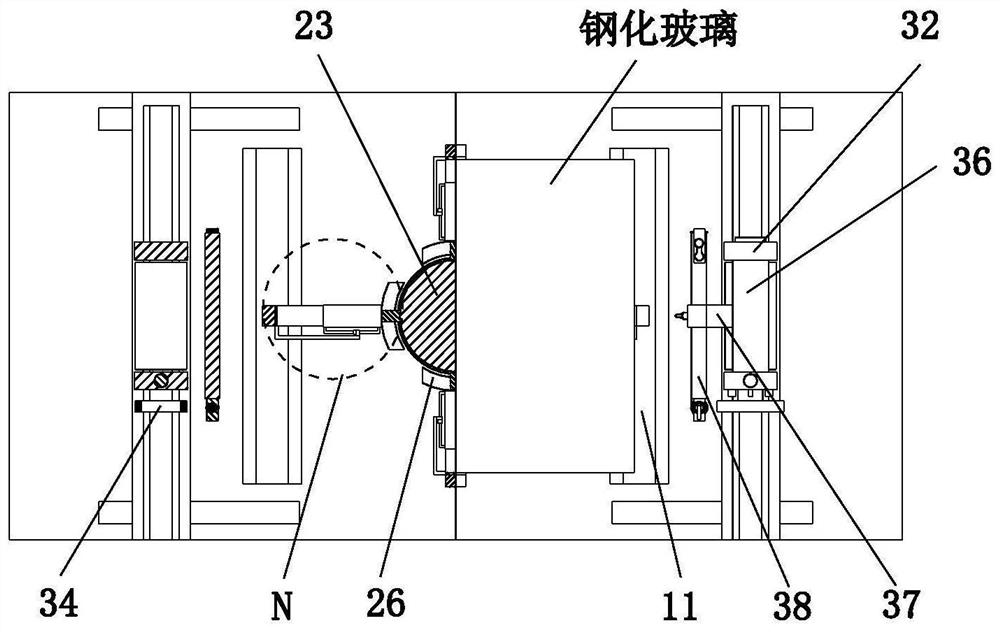

A kind of tempered glass production and manufacturing edge grinding machine and grinding method

ActiveCN111203775BWide range of sizesImprove sanding effectEdge grinding machinesGrinding carriagesToughened glassMaterials science

The invention relates to an edge grinding machine for the production and manufacture of tempered glass, which comprises a worktable, a clamping device and a grinding device. The device, the lower end of the grinding device and the upper end surface of the worktable are in a sliding fit. The present invention provides an edge grinding machine and a grinding method for the production of tempered glass. The clamping device of the structure clamps the tempered glass, which expands the size range of tempered glass that the equipment can adapt to, and improves the overall utilization rate of the equipment. Grinding effect on the perimeter of the glass.

Owner:南京道远玻璃科技有限公司

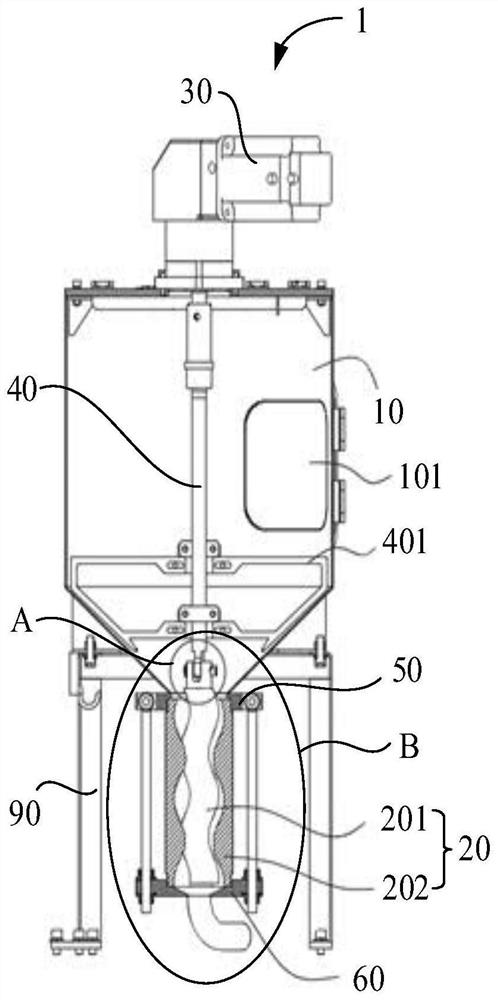

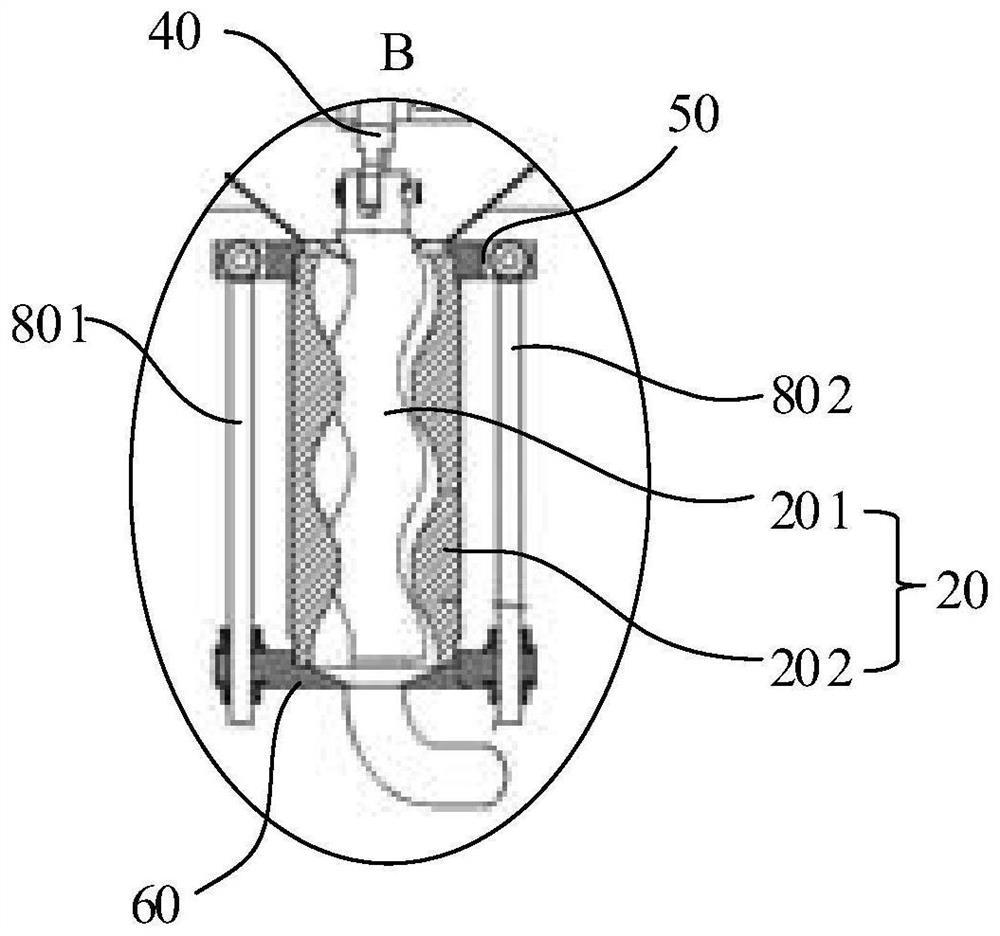

Feeding device and spraying machine

InactiveCN113843064AEasy to repair and replaceQuick releaseBuilding constructionsLiquid spraying apparatusEngineeringMachine

The invention relates to the technical field of coating machines, and provides a feeding device and a coating machine. The feeding device comprises a supporting frame, a material barrel, a screw pump and a driving mechanism; the material barrel is arranged on the supporting frame, and a discharging opening is formed in the bottom of the material barrel; the screw pump comprises a screw and a screw bushing arranged outside the screw in a sleeving mode, a first end of the screw bushing communicates with the discharging opening, and a second end of the screw bushing is connected with a conveying pipe; and the driving mechanism comprises a driving part and a stirring shaft arranged in the material barrel, one end of the stirring shaft is connected to the driving part, the other end of the stirring shaft is connected with the screw through a quick release mechanism, and the driving part is used for driving the stirring shaft to rotate and driving the screw to rotate relative to the screw bushing. According to the technical scheme, the mounting and dismounting efficiency of the screw pump can be effectively improved, the maintenance and replacement efficiency of the screw pump is effectively improved, and the time and labor cost of maintenance and replacement of the screw pump are greatly reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

A magnetic power container transfer vehicle

ActiveCN104229409BImprove applicabilityAvoid problems with cross work areasWagons/vansCargo supporting/securing componentsMagnetic energyConductor Coil

The invention discloses a magnetomotive container transfer vehicle. The magnetomotive container transfer vehicle comprises a vehicle body, wheel sets, a permanent magnet, a plurality of drive windings, tracks and a calibrated wheel set, wherein the drive windings are arranged on the ground, the permanent magnet is arranged at the lower part of the vehicle body, the drive windings are used for converting electric energy into magnetic energy to interact with the permanent magnet, and the container transfer vehicle is pushed to run; the calibrated wheel set is mounted on at least one of the wheel sets, the calibrated wheel set is provided with an encoder for detecting the running speed and distance of the container transfer vehicle, the calibrated wheel set is used for stably pressing calibrated wheels on the tracks on the ground depending on the effect of a pressure spring, so that accurate running speed and distance detected by the encoder are guaranteed; the vehicle body comprises cross beams and longitudinal beams, the upper parts of the two ends of the longitudinal beams are welded with fixed baffle plates, a plurality of movable baffle plates are arranged in the length direction of the cross beams, and the fixed baffle plates and the movable baffle plates play a role in stopping containers. The magnetomotive container transfer vehicle is zero-pollution, zero-emission, high in degree of automation, high in work efficiency, low in comprehensive energy consumption and high in applicability.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Magnetic stop mechanism in portable lifting device

InactiveCN101710492BPrevent slippingEffective balanceInstrumental componentsEngineeringViscous resistance

Owner:NANJING UNIV

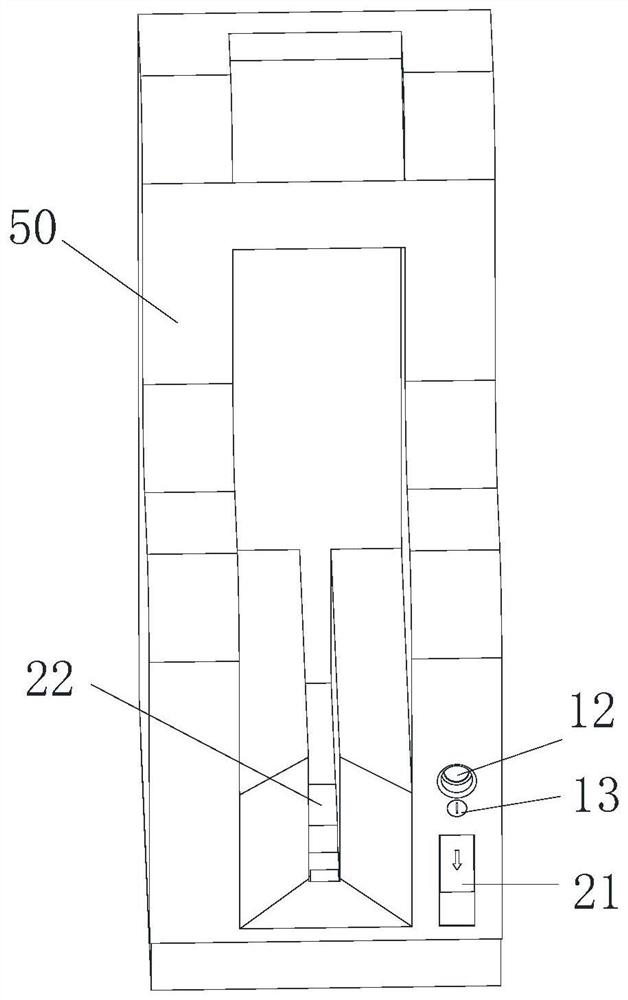

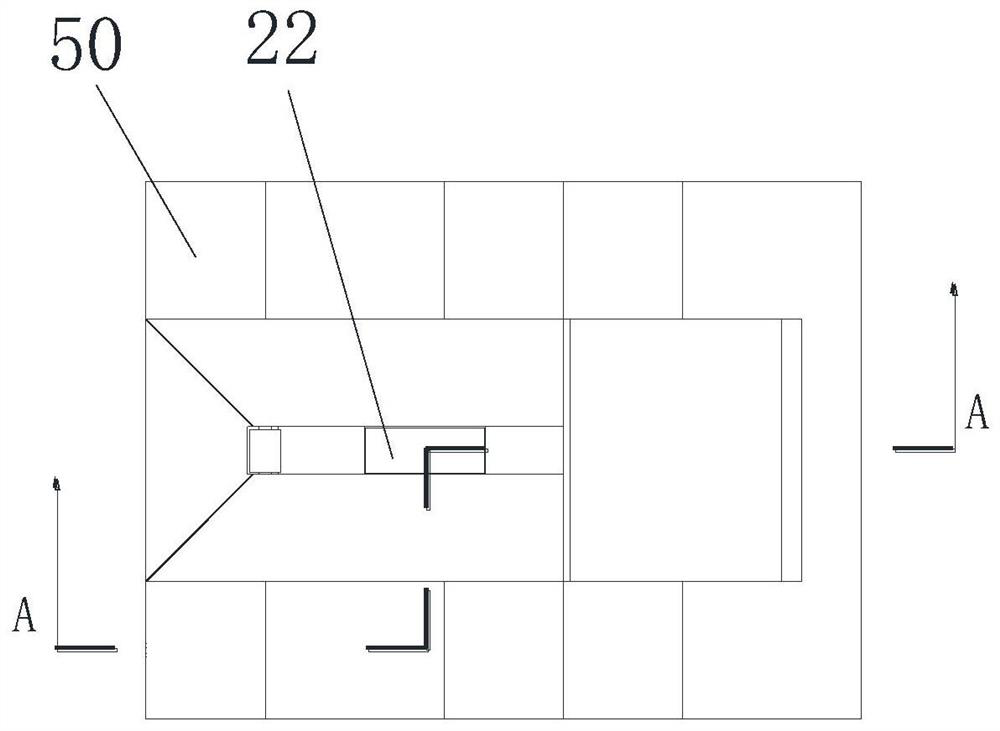

Locking mechanism and lock pile

ActiveCN108820083BPlay a stop rolePrevent extractionAnti-theft cycle devicesCycle standsStructural engineeringMechanical engineering

The invention provides a locking mechanism and a bicycle locking pile. The locking mechanism comprises a shell, a baffle plate assembly, a locking strip assembly and a locking body assembly, wherein an opening is formed in the shell; a baffle plate is arranged on the baffle plate assembly; the baffle plate is movably arranged in the opening to close or open the opening; the locking strip assemblycan be accommodated within the shell; a locking strip is arranged on the locking strip assembly; when the baffle plate opens at least one part of the opening, one part of the locking strip can extendout of the shell from the opening; the locking body assembly is arranged in the shell; and when the locking strip is wound on a locked part and is inserted into the locking body assembly, the lockingbody assembly can lock the locking strip. According to the locking mechanism and the bicycle locking pile, the problem of poor adaptability of the bicycle locking pile in the prior art is solved.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

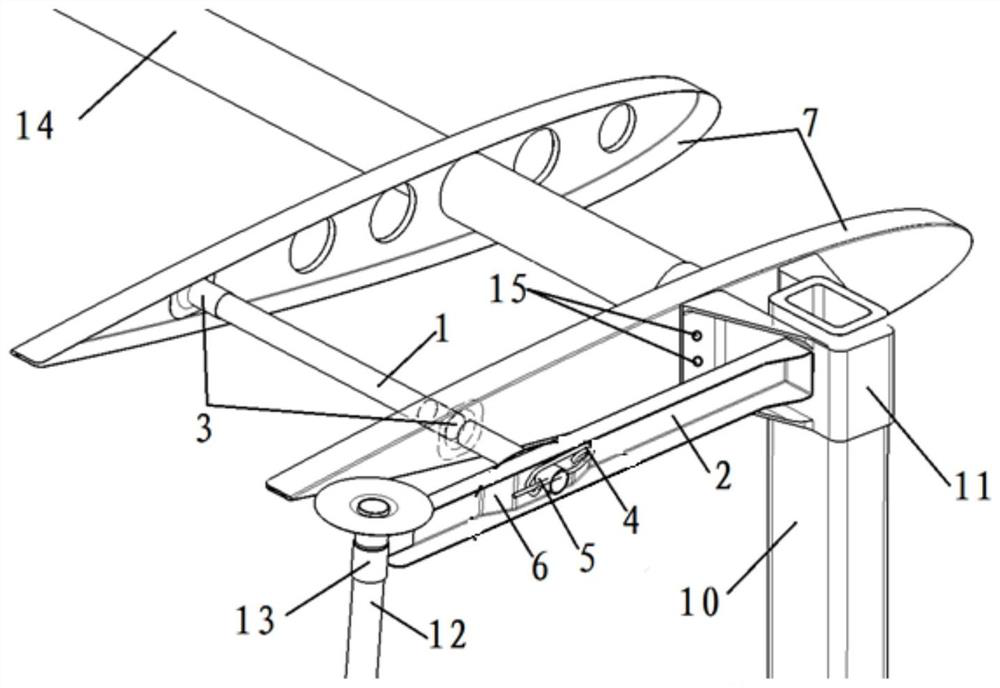

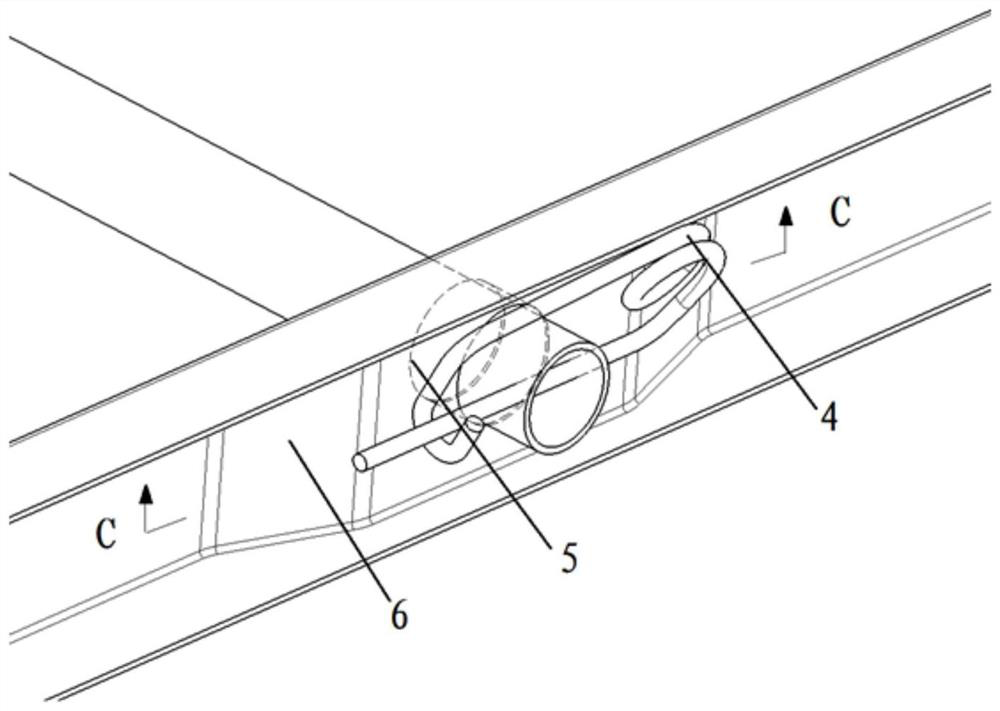

Quick connecting structure and connecting method for empennage of unmanned aerial vehicle

PendingCN114408159AShort production cycleLow costAircraft stabilisationWeight reductionAerospace engineeringStructural engineering

The rapid connecting structure comprises a horizontal empennage butt joint beam, a vertical empennage box-shaped reinforcing piece, a stop flange and a stop piece, the horizontal empennage butt joint beam is a composite material round pipe, penetrates through a horizontal empennage rib web plate and is fixed to the rib web plate through the stop flange, the front end of the horizontal empennage butt joint beam is exposed out of a horizontal empennage, and the stop piece is fixed to the horizontal empennage box-shaped reinforcing piece. The front end of the horizontal empennage butt-joint beam is inserted into a butt-joint hole preset in the vertical empennage box-shaped reinforcing piece, the vertical empennage box-shaped reinforcing piece is of a composite laminated plate structure with a C-shaped section and is located at the end of a vertical empennage, and a stop hole is formed in the front end of the horizontal empennage butt-joint beam. In addition, the front end of the horizontal tail butt-joint beam is limited in an abdominal cavity on one side of the vertical tail box-shaped reinforcing piece through a retainer.

Owner:XI'AN AIRCRAFT INTERNATIONAL

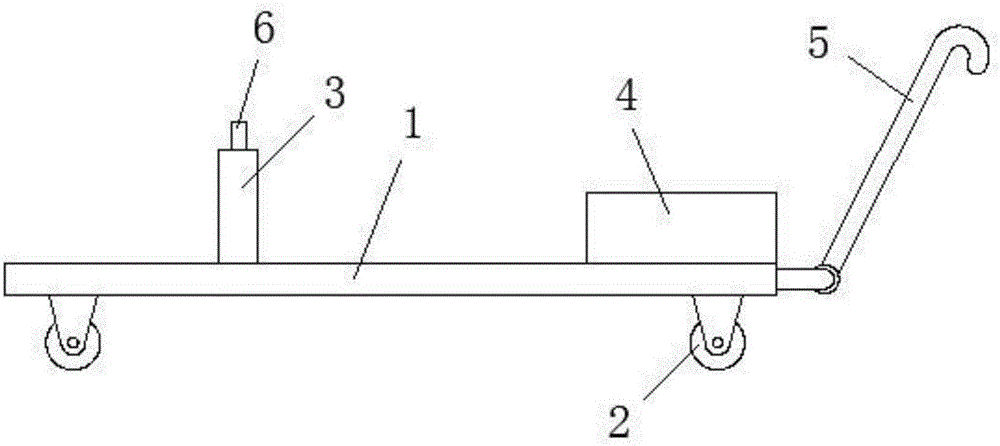

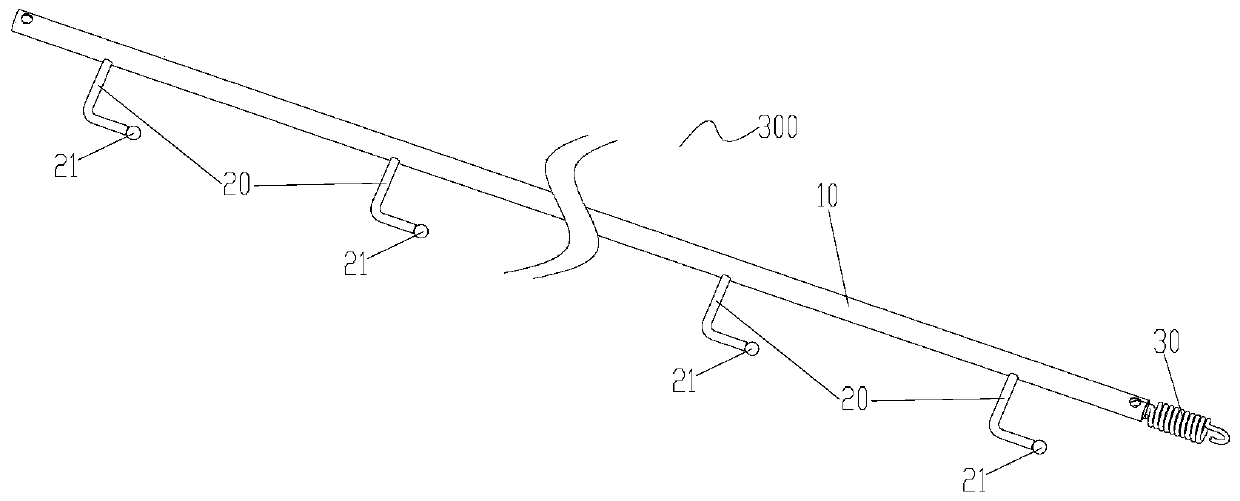

Farm tool trailer

InactiveCN106627701APlay a stop roleThe overall structure is simple and reliableHand carts with multiple axesEngineeringMechanical engineering

The invention discloses a farm tool trailer which comprises a sweeping board. A plurality of wheels are arranged at the bottom of the trailer board. A supporting board, a coaming and a hanging arm are arranged on the upper side of the trailer board. The coaming is located on the front side of the trailer board. The hanging arm is hinged to the front end of the trailer board. A hook is arranged at the front end of the hanging arm. An opening of the coaming faces one side of the supporting board. A plurality of partition boards are transversely arranged on the supporting board. According to the farm tool trailer, one end of a handle of a farm tool is placed into the coaming, the working end of the farm tool is arranged on the supporting board in a lapped mode, different farm tools are separated through the partition board on the supporting board, the stop effect is achieved, and even if the trailer is advanced on a bumpy road, the farm tools will not likely to be bumped out; the trailer board can be hung to other traffic tools through the hanging arm so as to replace manpower; the whole structure is simple and reliable, and the practicability is high.

Owner:SUZHOU JINGWEI AGRI PROD

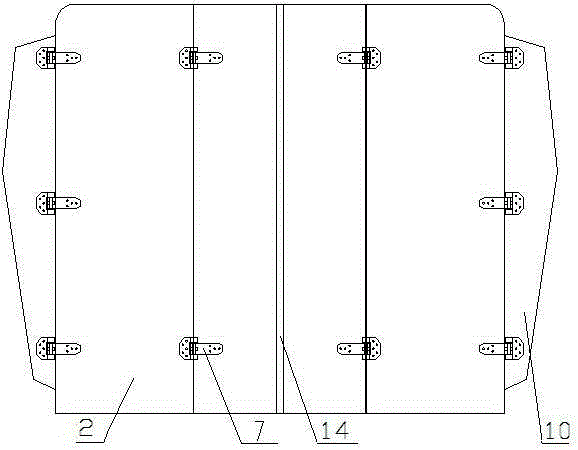

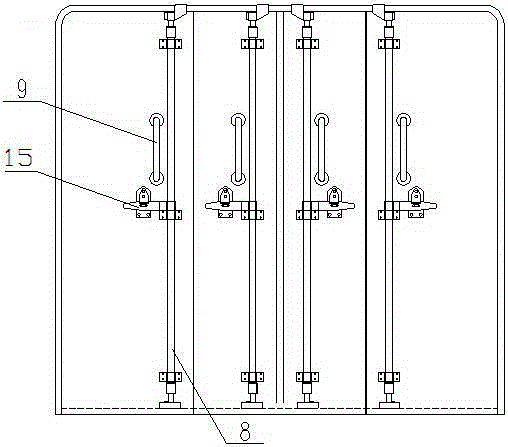

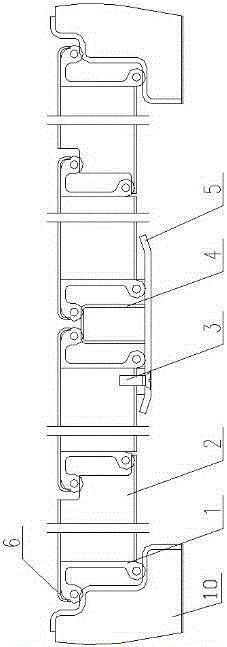

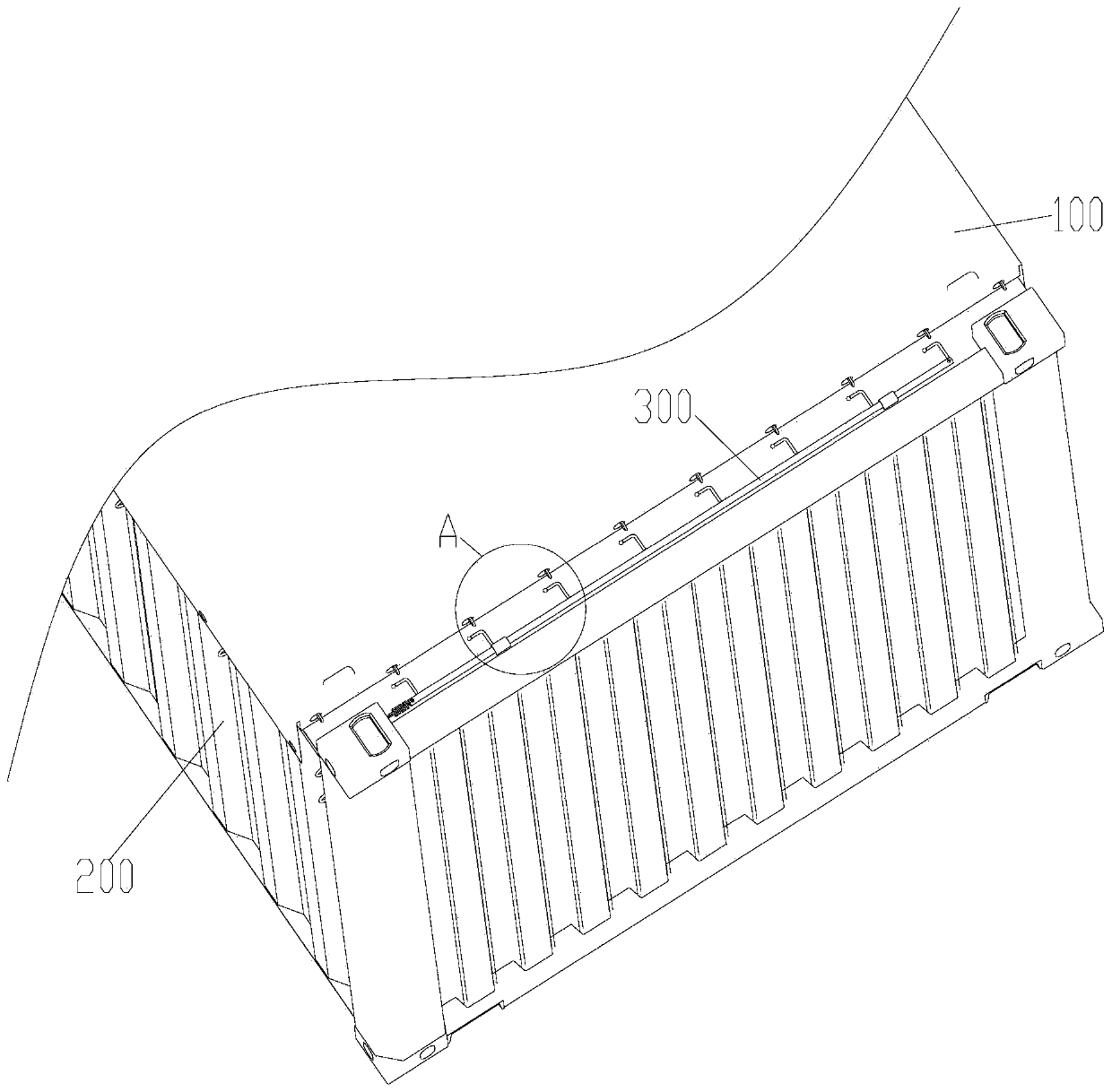

Locking structure and container having the same

ActiveCN108313558BPlay a stop roleImprove stabilityLarge containersMechanical engineeringEngineering

The invention provides a locking structure and a container with the same. The locking structure is used for fixing a tarpaulin on a body of the container; the locking structure comprises a locking rodconnected with the body, and a locking hook arranged on the locking rod for moving along with the locking rod; and when the locking hook is inserted in a locking ring on the body, the locking hook stops a locking hole structure of the tarpaulin sleeving the locking ring to prevent deviation of the locking hole structure from the locking ring. The locking structure solves the problem of time and labor wastes in the operation process of covering the tarpaulin on the body and connecting with the body in the prior art.

Owner:CRRC QIQIHAR ROLLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com