Automatic feeding mechanism and method for miniature machine tool

A technology of automatic feeding and machine tools, applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of lack of stability, impractical micro machine tools, and no effective and practical feeding mechanism for micro machine tools, etc., to achieve The operation is clear and light, and the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment is a micro-drilling and milling machine table X-axis miniature automatic feed mechanism, using a single-speed AC permanent magnet synchronous motor input power 28W, voltage 220V, output shaft speed 10 rpm, micro-drilling and milling machine table X-axis screw The screw pitch is 1.5mm, and the X-axis automatic feed speed of the worktable is 15mm / min, which is completely suitable for the automatic feed processing of parts with a diameter of 3-6mm end mills. The power of the driving motor of the miniature automatic feeding mechanism is only equivalent to one-tenth of the power of the driving motor of the original mechanism, and one-fifth of the weight and cost.

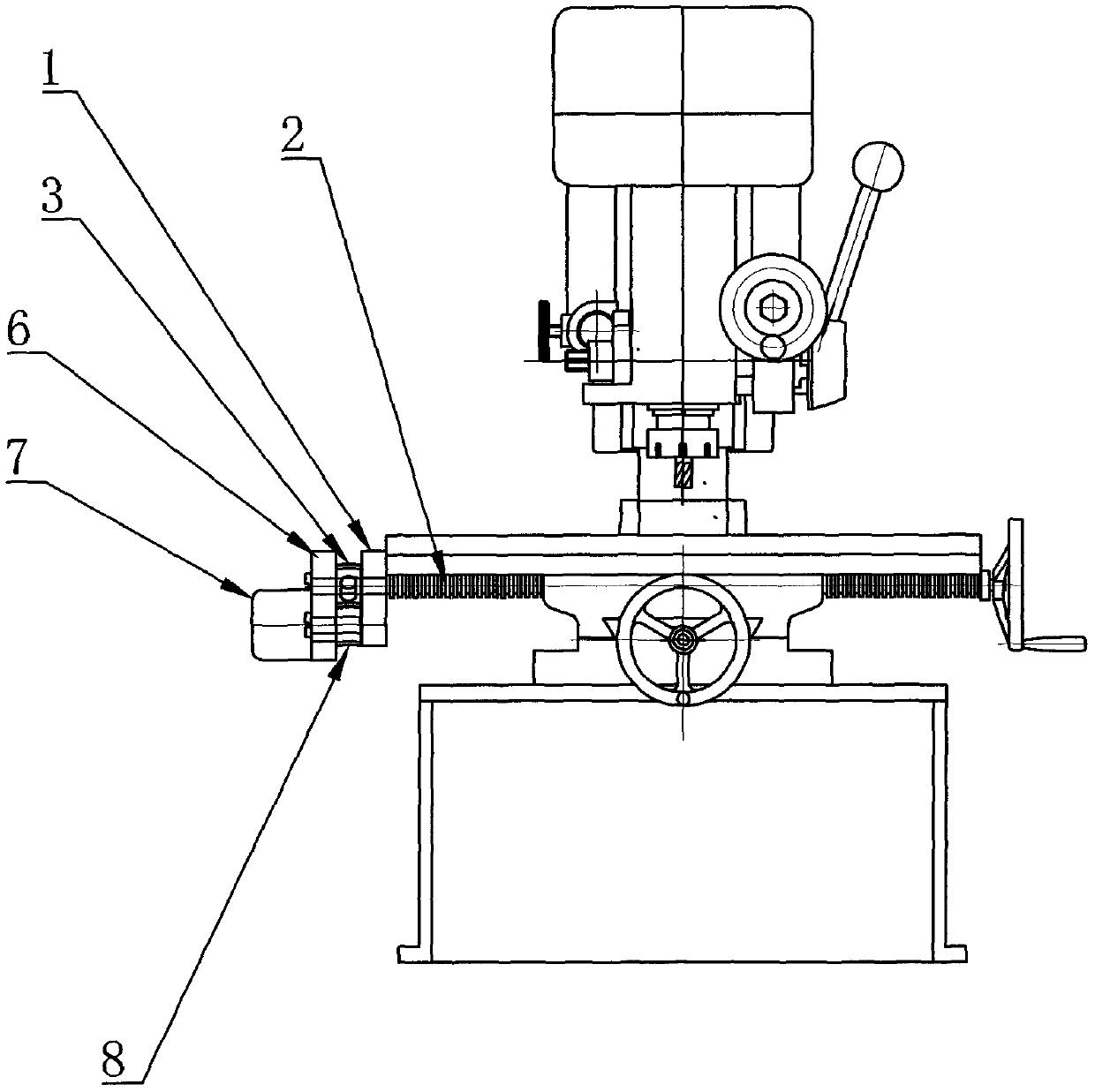

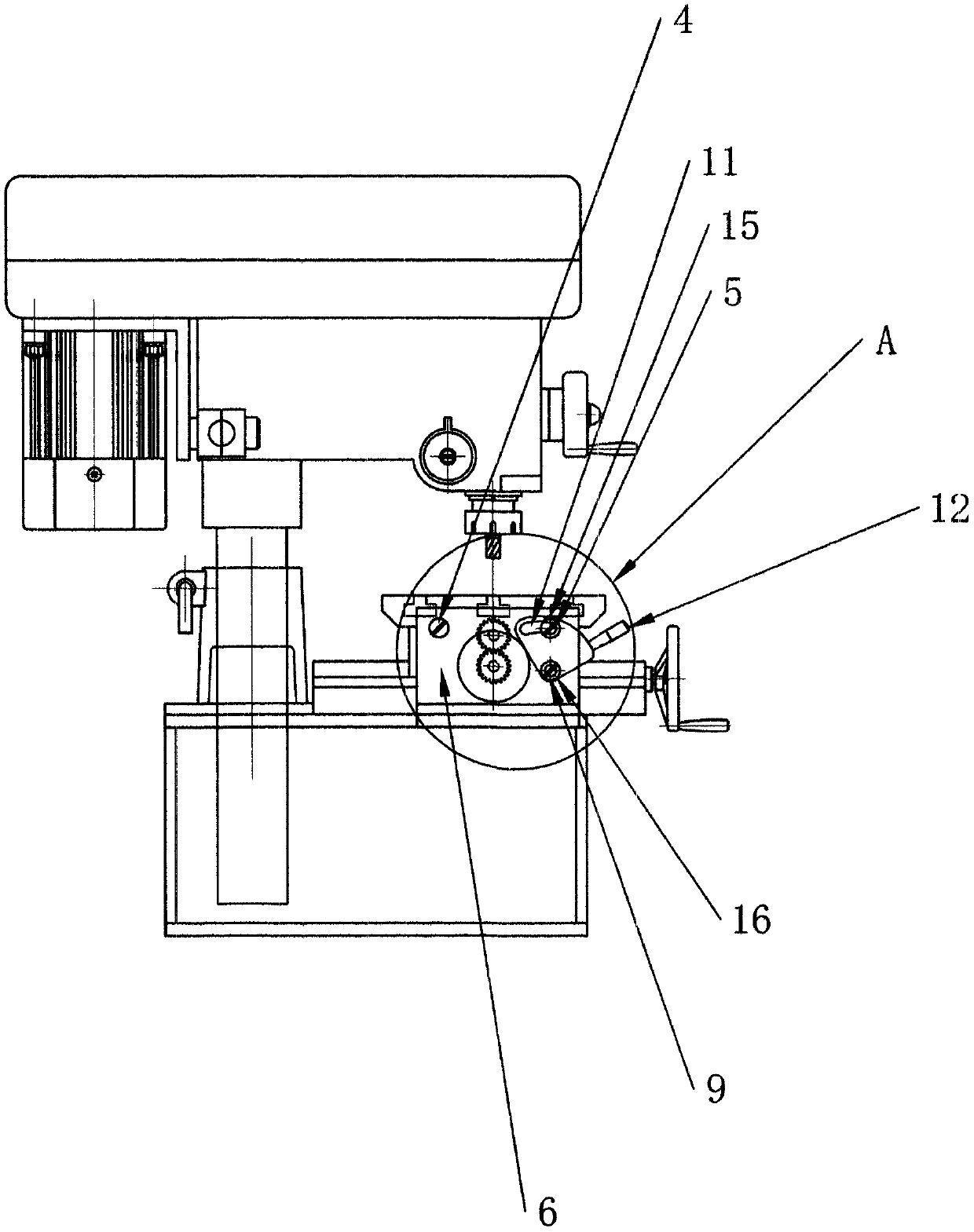

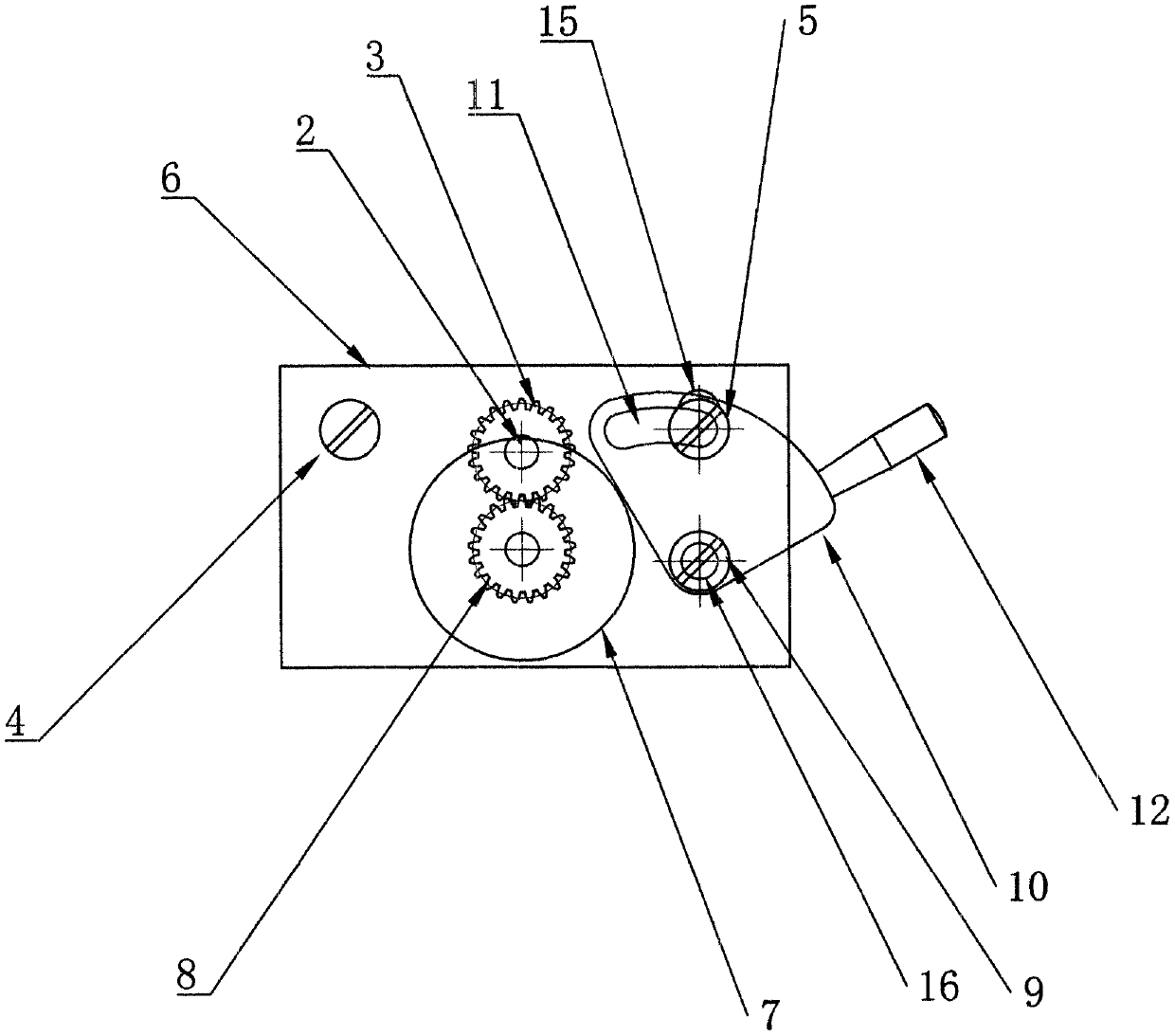

[0081] Depend on Figure 1 to Figure 7 As shown, the present embodiment is located at the automatic feeding mechanism and method of the micro-machine tool of the present invention. The gear 3 is combined; the driven screw 2 is threadedly connected with the machine tool, and the driven screw 2 pass...

Embodiment 2

[0086] Depend on Figure 8 to Figure 10 In another embodiment of the present invention shown, on the basis of Embodiment 1, the overall structure can be arranged on the machine tool.

Embodiment 3

[0088] Figure 11 to Figure 13 On the basis of Embodiment 1 and Embodiment 2, another embodiment of the fan-shaped plate 10 in the automatic feeding mechanism and method of the micro machine tool of the present invention is shown. In order to make the toggle adjustment of the fan-shaped plate 10 more stable, it is not necessary to will loosen, on the basis of Embodiments 1 and 2, the fan-shaped groove 11 of the original fan-shaped plate 10 is changed to include the first fan-shaped groove 19 and the second fan-shaped groove 20, the second fan-shaped groove 20 and the first fan-shaped groove 19 In the horizontal position, the second fan-shaped groove 20 is higher than the position of the first fan-shaped groove 19, and the radius of the second fan-shaped groove 20 is greater than the first fan-shaped groove 19, but the groove body of the first fan-shaped groove 19 and the second fan-shaped groove 20 The width is the same, and the first fan-shaped groove 19 and the second fan-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com