Cast-molded lifting hook

A casting and hook technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of safety hazards, the connection between the lifting ring and the hook part breaking, slipping, etc., to avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

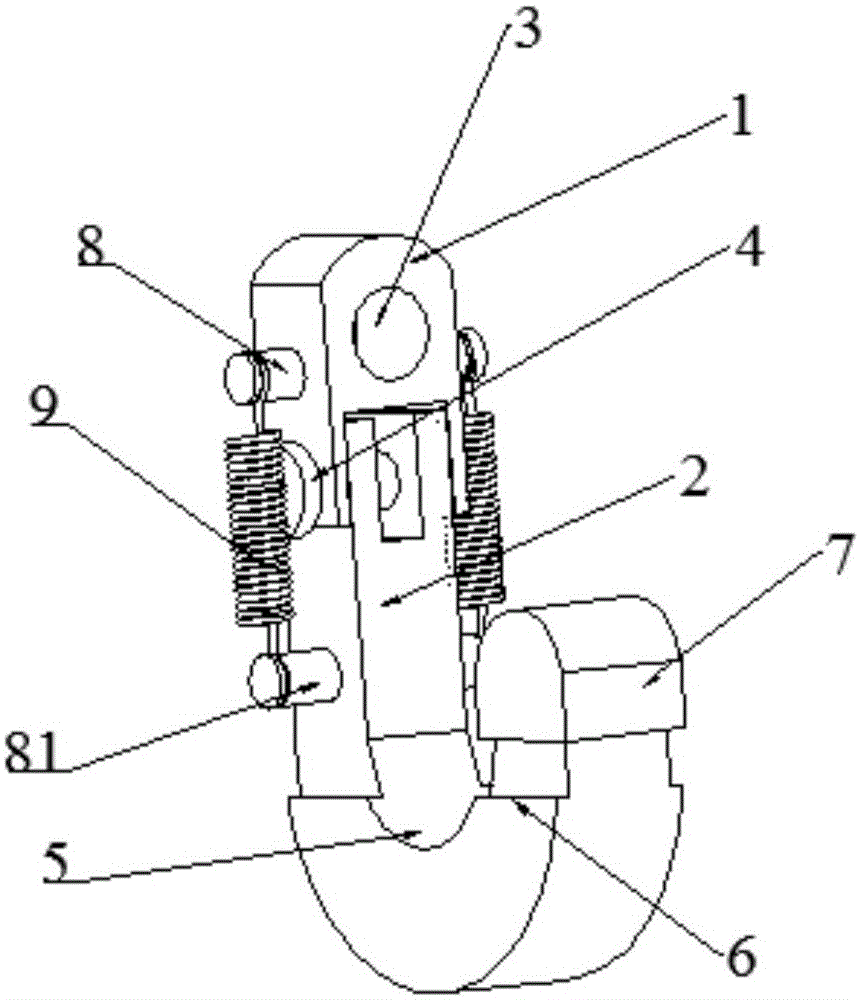

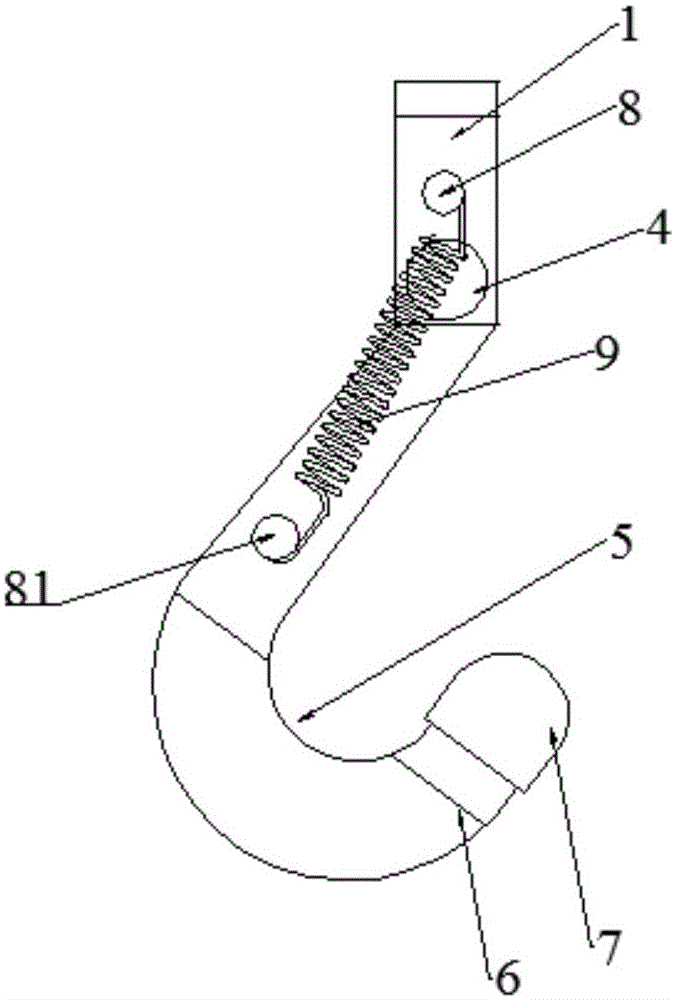

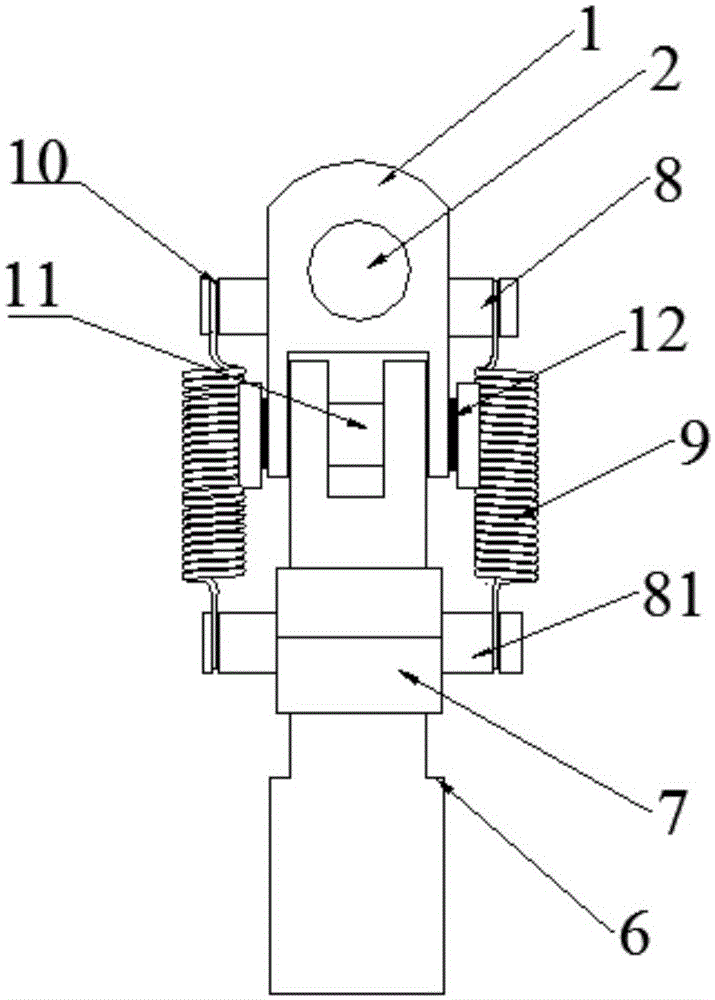

[0017] Such as figure 1 , figure 2 As shown, the present invention provides a cast-molded suspension hook, which includes a suspension ring 1, a connecting hole 3 in the middle of the suspension ring 1, a hook part 2 hingedly connected to the suspension ring 1, and is arranged along the central axis of the suspension ring 2. The bearing hole 5 is characterized in that an upper fixed shaft 8 is provided on both sides of the suspension ring 1, and a lower fixed shaft 9 is provided on both sides of the hook portion 2 close to the suspension ring 1, and the upper fixed shaft 9 is provided on both sides of the suspension ring 1. A spring member 9 is connected between the shaft 8 and the lower fixed shaft 9, which plays a buffering role and prevents the hook part 2 from swinging too much during operation, causing the loaded object t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com