Material conveying roller bed and stop mechanism thereof

A technology of stopper mechanism and conveying roller table, which is applied in the direction of conveyor objects, roller table, transportation and packaging, etc., can solve problems such as equipment damage, accident, material falling down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present application will be described in detail below with reference to the accompanying drawings and in combination with implementation manners.

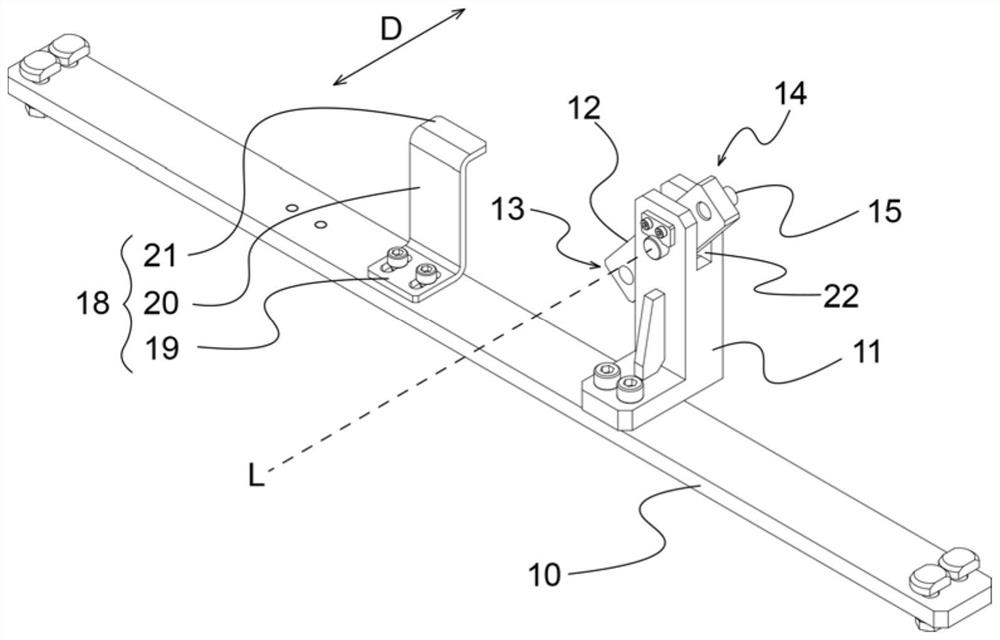

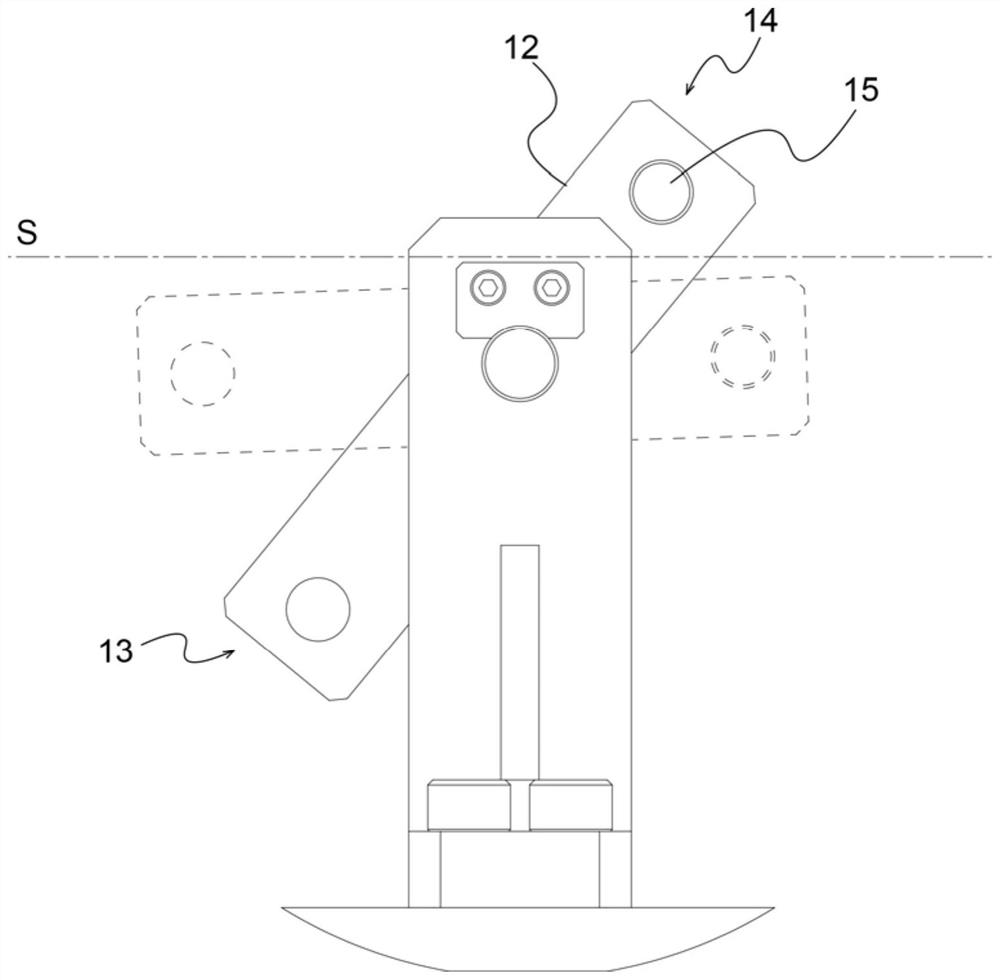

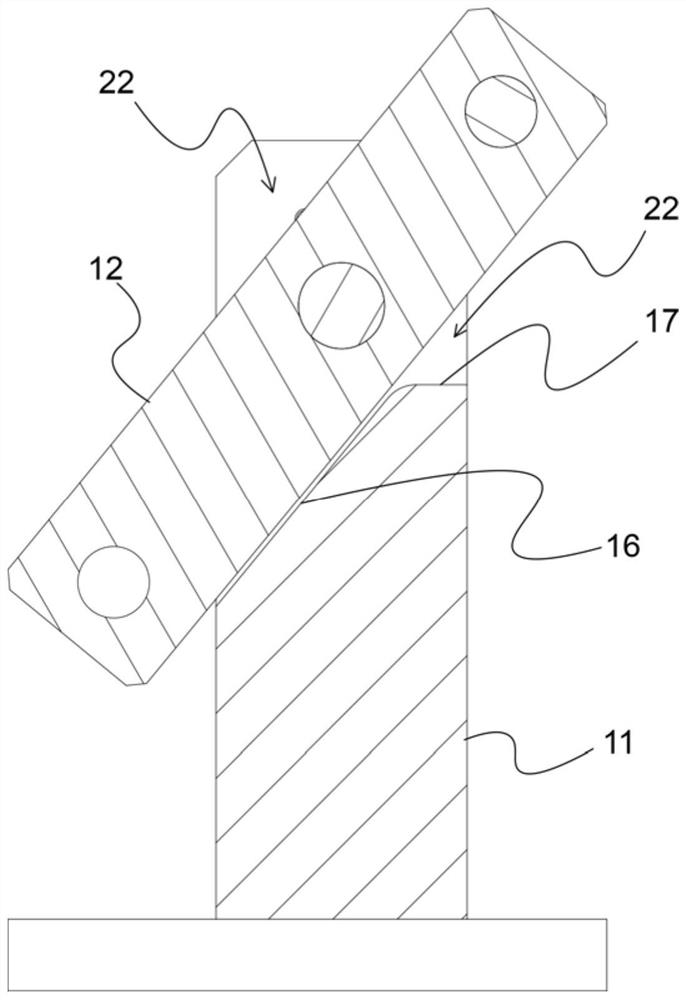

[0026] Such as figure 1 As shown, according to the present application, a stop mechanism for a material conveying roller table is provided, and the stop mechanism includes: a horizontal underframe 10 fixedly arranged at the opening of the material conveying roller table; a vertical support 11 , the vertical bracket 11 is fixedly installed on the transverse chassis 10 and extends upwards on the outside of the opening of the material conveying roller table; the stopper 12, the stopper 12 surrounds the center of the conveying direction D parallel to the material conveying roller table The axis L is hinged to the vertical bracket 11, and the hinge point of the stopper 12 and the vertical bracket 11 deviates from the center of gravity of the stopper 12, wherein the heavier end 13 and / or lighter end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com