Overload prevention combined type variable spring supporter and hanger utilizing threaded rod to lock

An anti-overload, combined technology, applied in the direction of springs, pipe supports, springs/shock absorbers, etc., can solve the problems of complicated installation operations, the inability to adjust the position of variable spring supports and hangers according to site conditions, and low safety performance. Achieve the effect of improving safety, facilitating maintenance operations, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

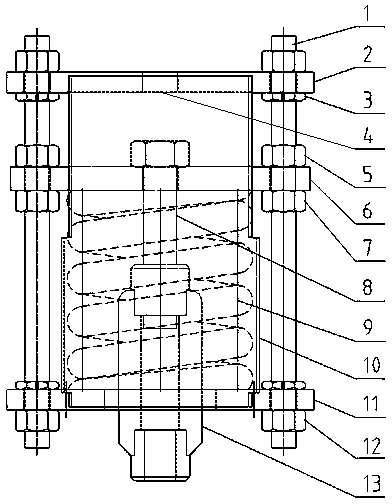

[0024] Such as figure 2 As shown, an anti-overload combined variable spring hanger that adopts screw locking, its structure includes an upper cover plate, a spring pressing plate, a spring, a spring housing, and a lower cover plate; wherein the spring pressing plate is arranged on the upper cover plate and the lower cover Between the plates, a spring is installed between the lower surface of the spring pressure plate and the upper surface of the lower cover, and the spring housing is arranged outside the spring, and its upper and lower ends are respectively connected and fixed with the upper cover and the lower cover; two locks Bolts respectively pass through the holes on the left and right sides of the upper cover plate, the bayonet sockets on the left and right sides of the spring pressure plate, and the holes on the left and right sides of the lower cover plate.

[0025] The upper cover is respectively connected with two locking bolts through two flat nuts, and a tie rod n...

Embodiment 2

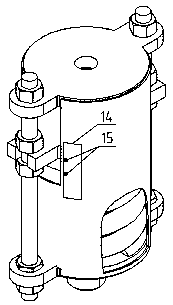

[0028] Such as image 3 As shown, an anti-overload combined variable spring hanger that adopts screw locking, its structure includes an upper cover plate, a spring pressing plate, a spring, a spring housing, and a lower cover plate; wherein the spring pressing plate is arranged on the upper cover plate and the lower cover Between the plates, a spring is installed between the lower surface of the spring pressure plate and the upper surface of the lower cover, and the spring housing is arranged outside the spring, and its upper and lower ends are respectively connected and fixed with the upper cover and the lower cover; two locks Bolts respectively pass through the holes on the left and right sides of the upper cover plate, the bayonet sockets on the left and right sides of the spring pressure plate, and the holes on the left and right sides of the lower cover plate.

[0029] The upper cover plate is respectively connected with two locking bolts through two flat nuts, a single h...

Embodiment 3

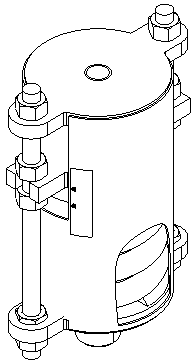

[0032] Such as Figure 4 As shown, an anti-overload combined variable spring hanger that adopts screw locking, its structure includes an upper cover plate, a spring pressing plate, a spring, a spring housing, and a lower cover plate; wherein the spring pressing plate is arranged on the upper cover plate and the lower cover Between the plates, a spring is installed between the lower surface of the spring pressure plate and the upper surface of the lower cover, and the spring housing is arranged outside the spring, and its upper and lower ends are respectively connected and fixed with the upper cover and the lower cover; two locks Bolts respectively pass through the holes on the left and right sides of the upper cover plate, the bayonet sockets on the left and right sides of the spring pressure plate, and the holes on the left and right sides of the lower cover plate.

[0033] The upper cover plate is respectively connected with two locking bolts through two flat nuts. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com