Quick connecting structure and connecting method for empennage of unmanned aerial vehicle

A quick-connect, unmanned aerial vehicle technology, applied in the directions of aircraft stability, aircraft parts, aircraft control, etc., can solve the problems of long installation and disassembly cycle, complex assembly process, large number of parts, etc., to achieve lightweight and reliable structure, easy disassembly, The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

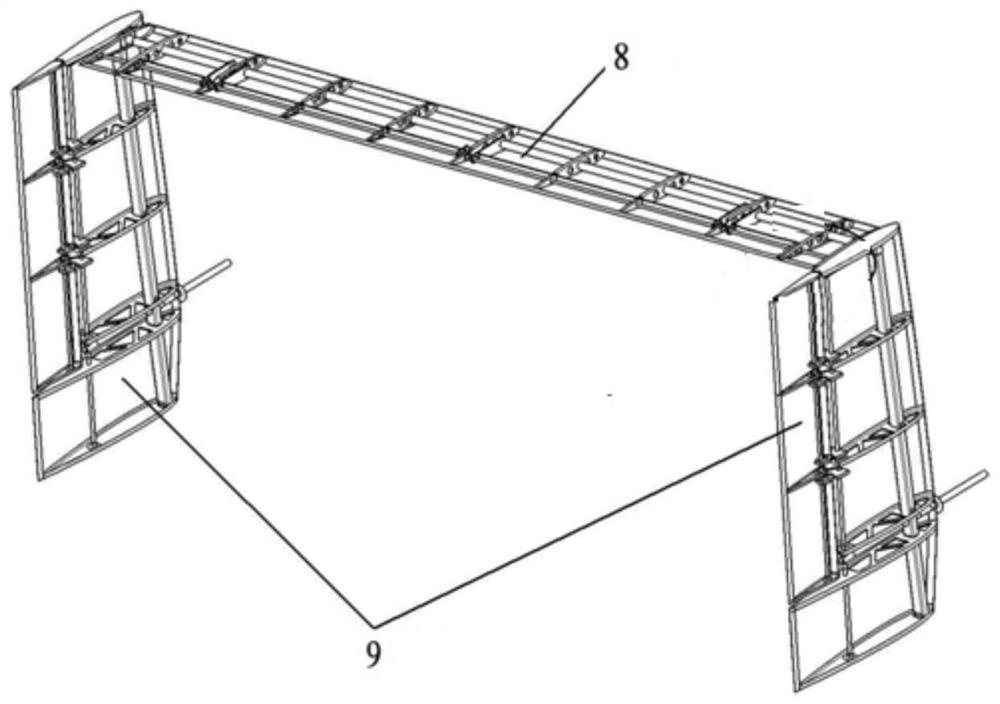

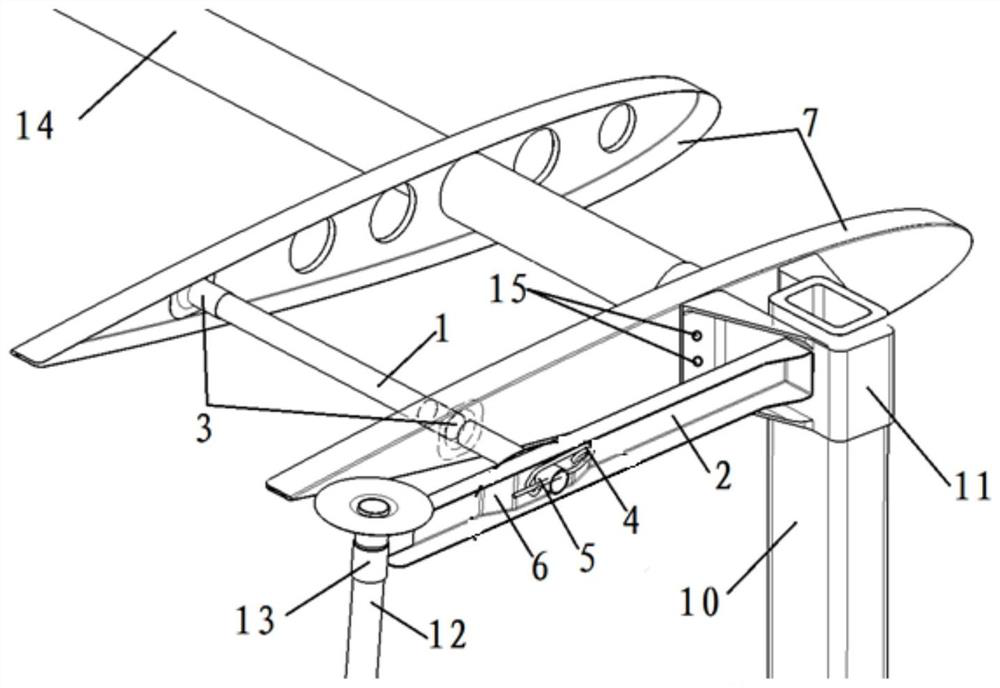

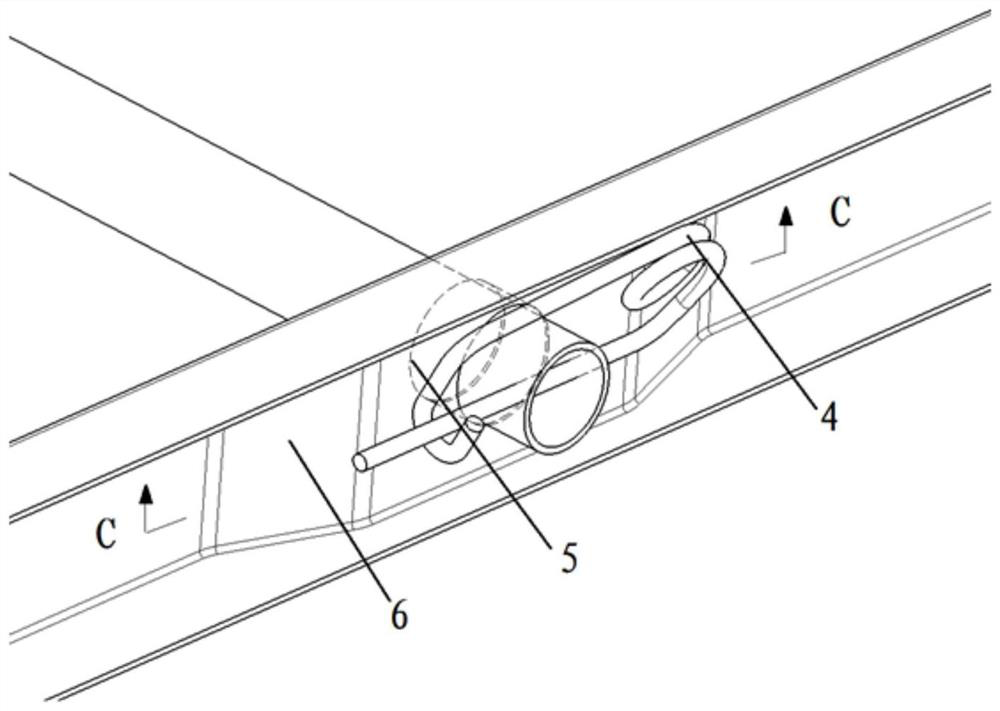

[0018] Referring to the accompanying drawings, the UAV empennage quick connection structure of the present application is a structure for connecting the horizontal empennage 8 and the vertical empennage 9 of the unmanned aerial vehicle, such as figure 1 As shown, a vertical tail 9 is respectively connected to both sides of the horizontal tail 8. The quick connection structure includes a horizontal empennage butt beam 1, a vertical empennage box reinforcement 2, a stop flange 3 and a stopper 4, and the horizontal empennage butt beam 1 is a composite circular tube, passing through the horizontal empennage The rib web 7 is fixed on the rib web through the stop flange 3, the horizontal empennage 8 is exposed at the front end of the horizontal empennage butt-joint beam 1, and the front end of the horizontal empennage butt-joint beam 1 is inserted into the preset butt joint hole on the vertical empennage box-shaped reinforcement 2 Inside, the vertical empennage box-shaped reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com