Magnetic stop mechanism in portable lifting device

A technology of a stop mechanism and a lifting device, which is applied to the parts and instruments of the instrument, can solve problems such as difficulty in locking, and achieve the effect of a reliable stop function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

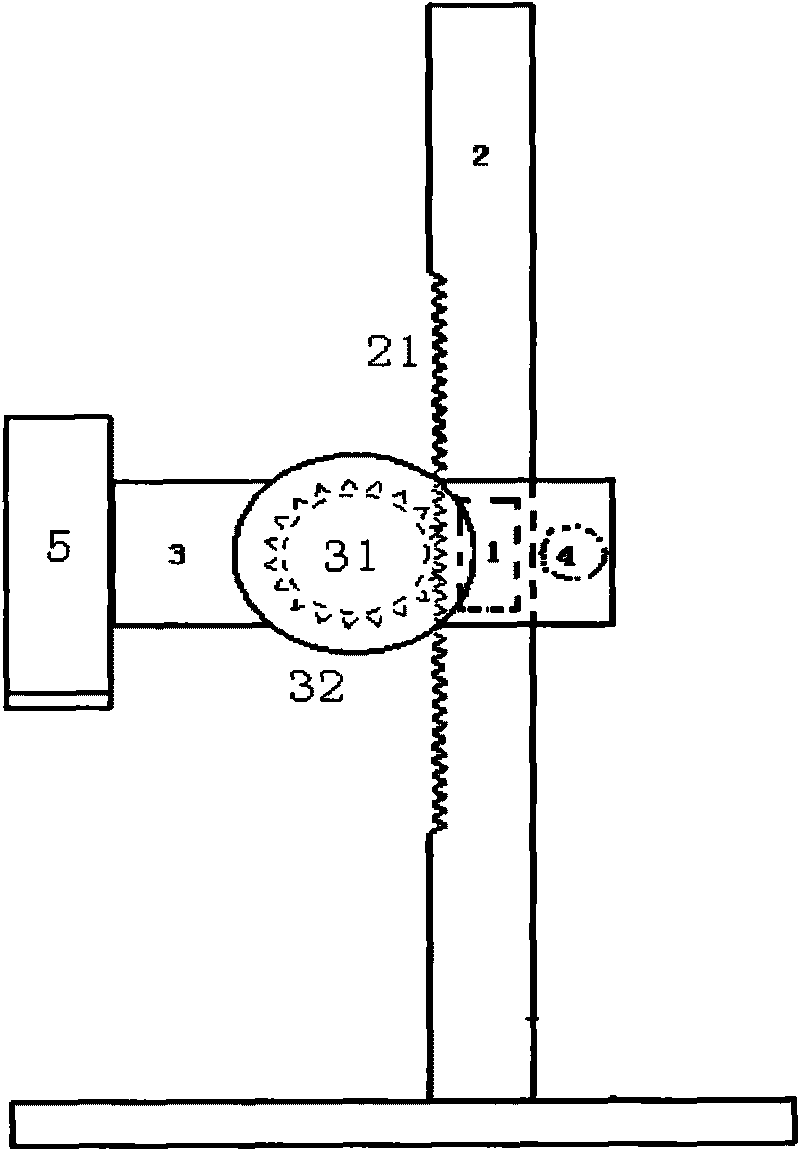

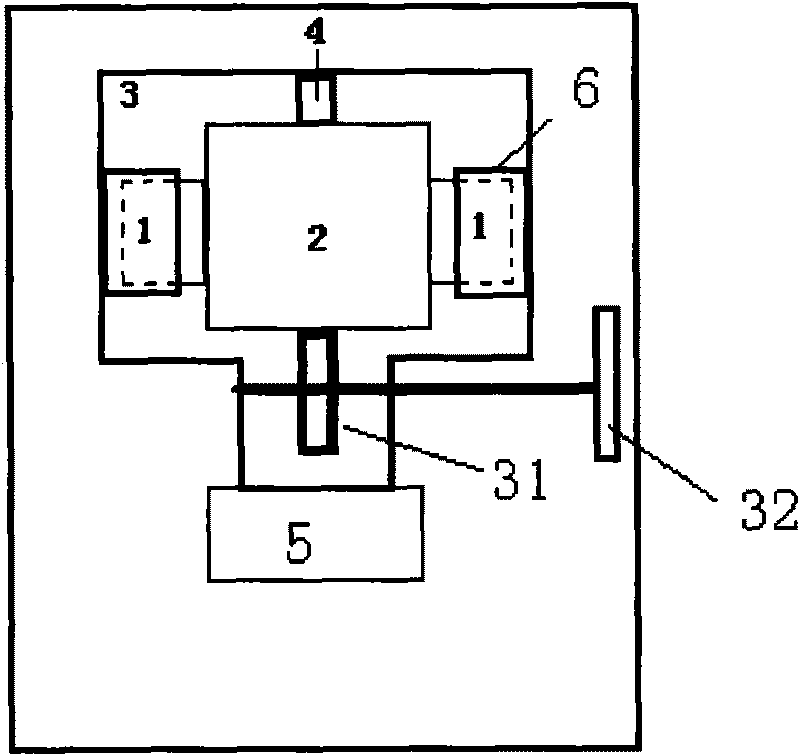

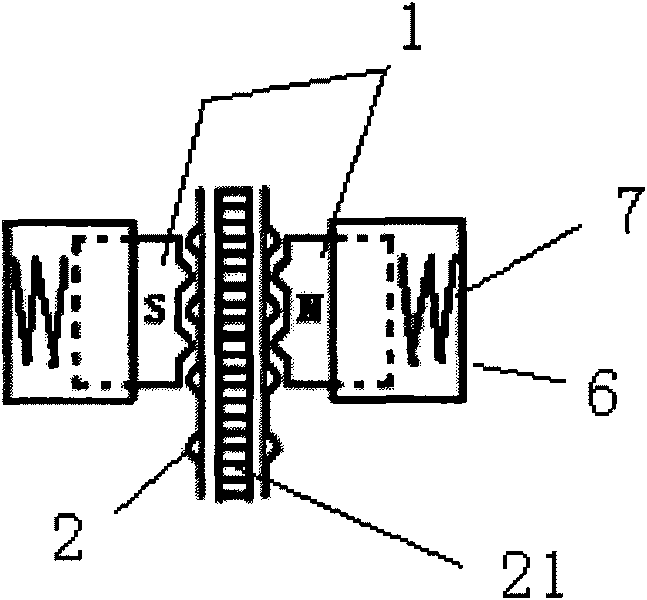

[0021] A kind of magnetic stop mechanism in the lightweight lifting device of the present invention, see figure 1 and figure 2 , the magnetic stop mechanism includes a strong magnetic slider group 1, a sliding guide rail 2, a movable part with hanging ears 3 and an adjusting roller 4. The ferromagnetic slider group 1 is two ferromagnetic sliders, the N and S poles of the pair of ferromagnetic sliders face each other across the sliding guide rail 2 and are adsorbed on both sides of the sliding guide rail 2 . The strong magnetic slider 1 is embedded in the movable part 3 with hanging ears, and a spring 7 is arranged between the strong magnetic slider 1 and the hanging ears 6 to keep an appropriate activity margin; There is a gear 31 adapted to the rack 21, and a rotary handle 32 for rotating the gear 31. The load 5 is connected with the movable part 3 with hanging ears. The movable part with hanging lugs pushes the magnetic slider to move up and down along the sliding guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com