An electrostatic flocking type high-elastic sound-absorbing flame-retardant melt-blown nonwoven fabric and its manufacturing method

A technology of melt-blown nonwovens and electrostatic flocking, which is applied in the textile field, can solve the problems of lack of sound-absorbing materials, etc., and achieve the effects of improving sound-absorbing effect, strong bending resistance, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

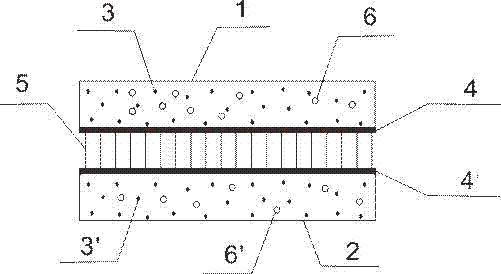

[0041] Electrostatic flocking high-elastic sound-absorbing flame-retardant melt-blown nonwoven fabric, including upper base fabric 1, lower base fabric 2, sound-absorbing particles 3, 3', upper adhesive film 4, lower adhesive film 4', fluff 5 And flame retardant powder 6, 6'. The upper base fabric 1 and the lower base fabric 2 are non-woven fabrics prepared by the melt-blown method. The sound-absorbing particles 3, 3' and flame-retardant powders 6, 6' are uniformly mixed, and the melt is extruded from the spinneret hole and subjected to high-speed hot air flow. When the superfine fibers are stretched to reach the condensed net curtain, the mixture of sound-absorbing particles 3, 3' and flame-retardant powder 6, 6' is blown and attached to the superfine fibers by hot air blowing, and the sound-absorbing particles 3 The superfine fiber with flame-retardant powder 6 relies on self-thermal bonding to make the upper base fabric 1, and the ultra-fine fiber with sound-absorbing parti...

Embodiment 2

[0053] Electrostatic flocking high-elastic sound-absorbing flame-retardant melt-blown nonwoven fabric, including upper base fabric 1, lower base fabric 2, sound-absorbing particles 3, 3', upper adhesive film 4, lower adhesive film 4', fluff 5 And flame retardant powder 6, 6'. The upper base fabric 1 and the lower base fabric 2 are non-woven fabrics prepared by the melt-blown method. The sound-absorbing particles 3, 3' and flame-retardant powders 6, 6 are evenly mixed, and the melt is extruded from the spinneret hole and subjected to high-speed hot air flow. When the superfine fibers are stretched to reach the condensed net curtain, the mixture of sound-absorbing particles 3, 3' and flame-retardant powder 6, 6' is blown and attached to the superfine fibers by hot air blowing, and the sound-absorbing particles 3 The superfine fiber with flame-retardant powder 6 relies on self-thermal bonding to make the upper base fabric 1, and the ultra-fine fiber with sound-absorbing particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com