Rack type container

A bench-type container and underframe technology, which is applied in the field of containers, can solve the problems of cumbersome operation, easy damage, and poor effect, and achieve the effect of good economy, standardized installation, and good operation coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

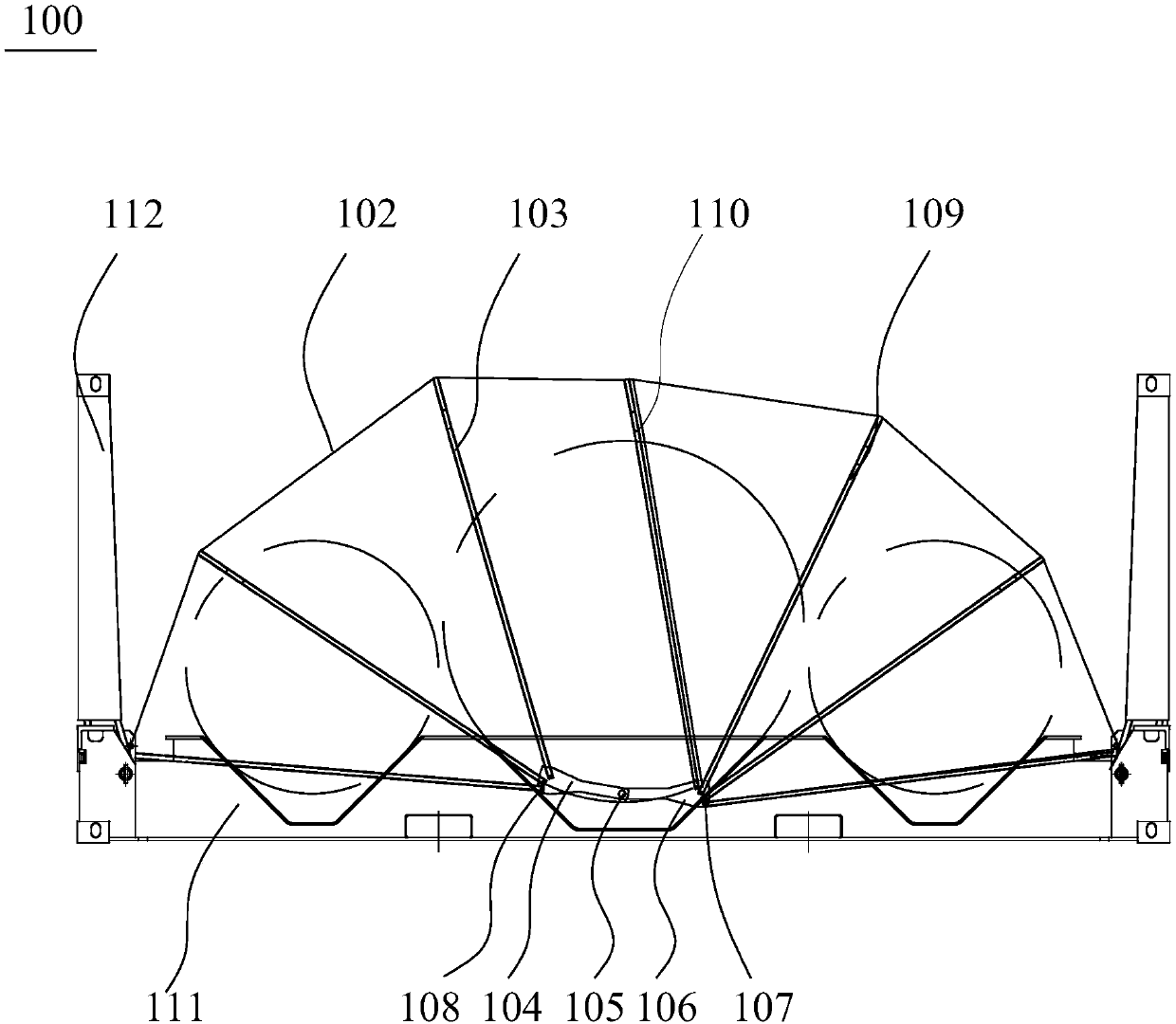

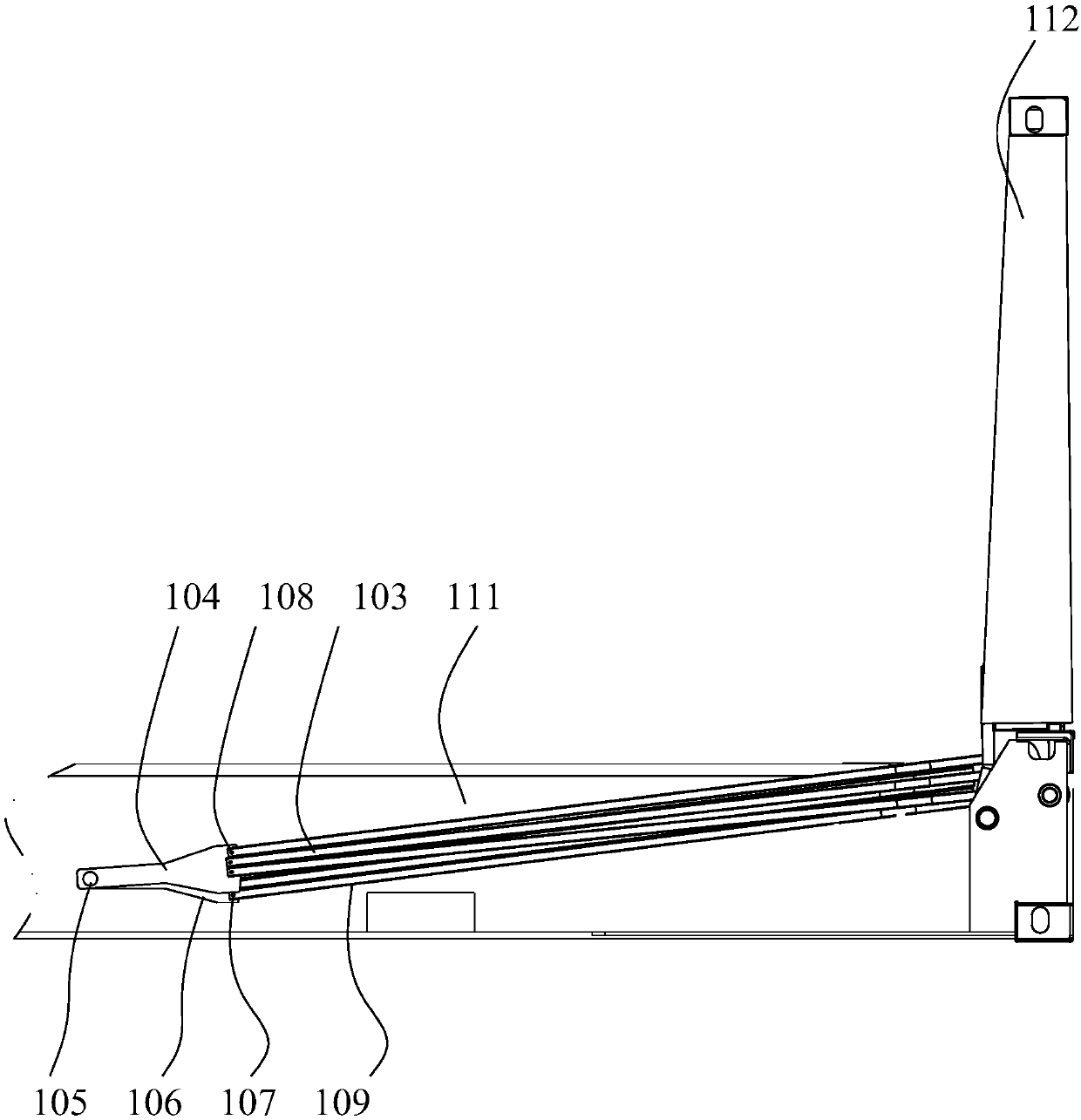

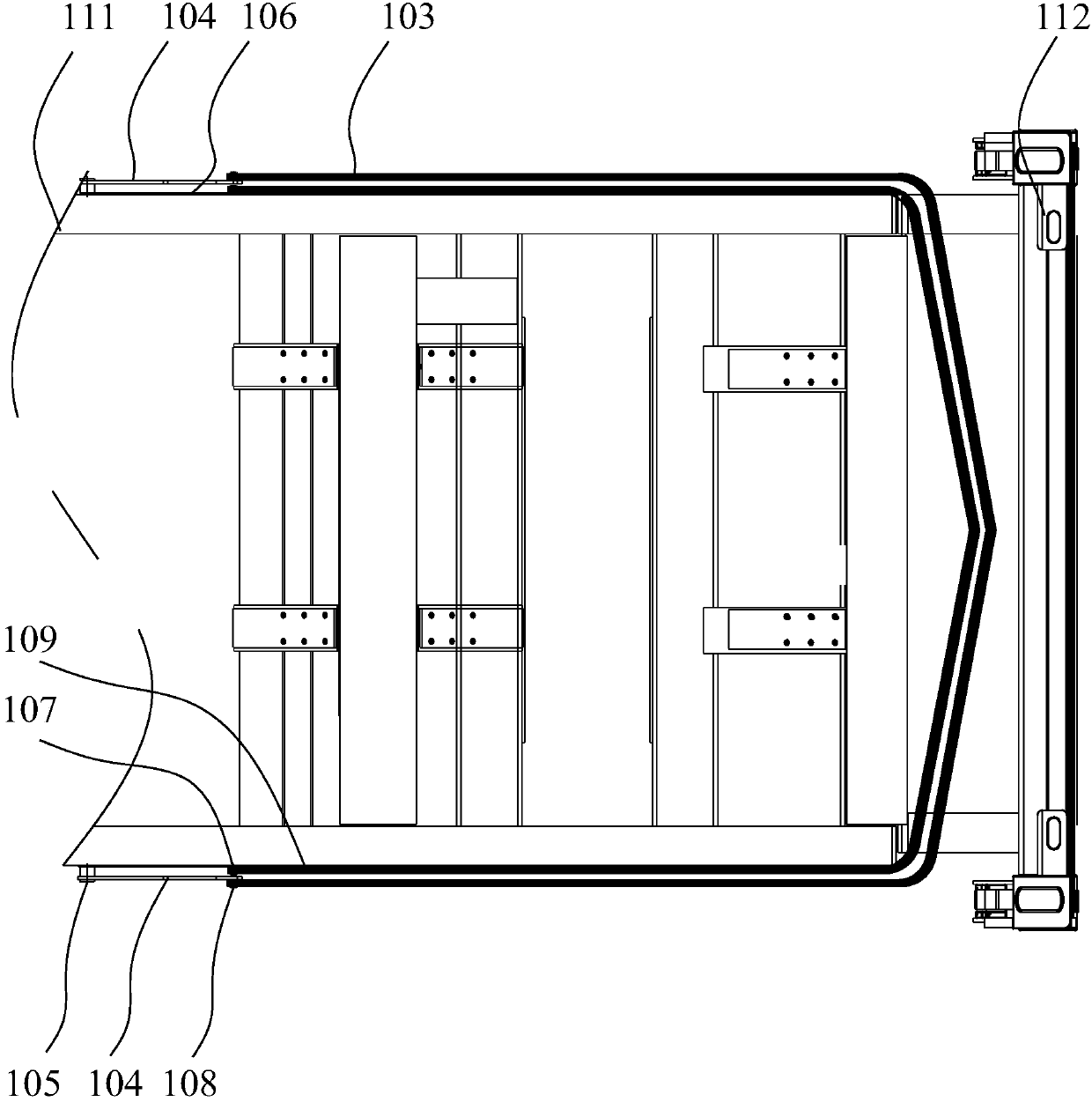

[0044] see Figure 1 to Figure 8 , In the first embodiment of the present invention, the hinged seats are arranged on both sides of the chassis. In other words, each side of the bottom frame is respectively provided with a hinge seat.

[0045] The awning device includes a tarpaulin 102 for covering the rain and a plurality of U-shaped support rods for supporting the tarpaulin 102, and the tarpaulin 102 is connected with the support rods. The tarpaulin 102 and the support rod can be fixedly connected or detachably connected. The two ends of the U-shaped support rod are respectively rotatably connected to the hinge seats provided on both sides of the chassis, for example in a hinged manner. Therefore, the awning device can be opened to cover the bottom frame and can be stored to be stacked on the bottom frame.

[0046] In addition, if Figure 6 As shown, the end of the bottom frame is provided with a receiving portion 113, and the receiving portion 113 is used to accommodate...

no. 2 approach

[0061] now go to Figure 9 , which shows a gantry container 200 according to a second embodiment of the present invention, the gantry container 200 comprising a chassis with a bottom side beam 211, an end wall 212, a first hinge 204 and a second hinge The hinge seat of the part 206 and the first support rod 203 pivotably connected with the first hinge part 204, the second support rod 209 pivotable with the second hinge part 206, and the first support rod 203 and the second support rod 209 The tarpaulin 202 that is fixedly connected by the support rod 209 .

[0062] In this embodiment, the structure of the first hinge part 204 and the plurality of first support rods 203 connected to the first hinge part 204 is substantially the same as that in the first embodiment. The first hinge portion 204 is pivotally connected (eg, hinged) about a shaft 205 connected to the base. But different from the first embodiment, the second hinge part 206 is fixedly connected to the side of the ch...

no. 3 approach

[0067] now go to Figure 10 , which shows a hinged seat of a gantry container according to a third embodiment of the present invention. In this embodiment, the first support rod 303 is disposed on the first hinge portion 304 , and the second support rod 309 is disposed on the second hinge portion 306 . Different from the above embodiments, the first hinge part 304 is sleeved on the rod 305 and can slide relative to the rod 305 , while the second hinge part 306 is fixedly arranged on the rod 305 . In other words, the first hinge part 104 is able to slide relative to the second hinge part 106 .

[0068] Of course, in an embodiment not shown, both the first hinge 104 and the second hinge 106 can slide relative to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com