A navigation method and agv based on indoor microwave base station

A navigation method and base station technology, applied in two-dimensional position/channel control and other directions, can solve the problems of cumulative error, high requirements for suitable occasions, and great influence by obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

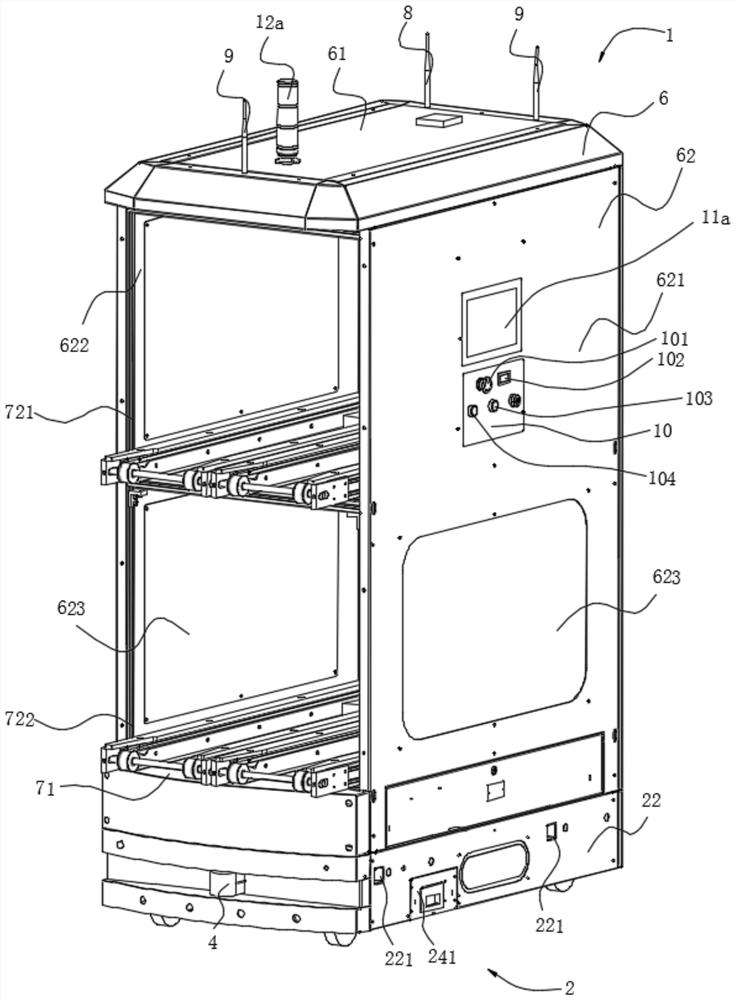

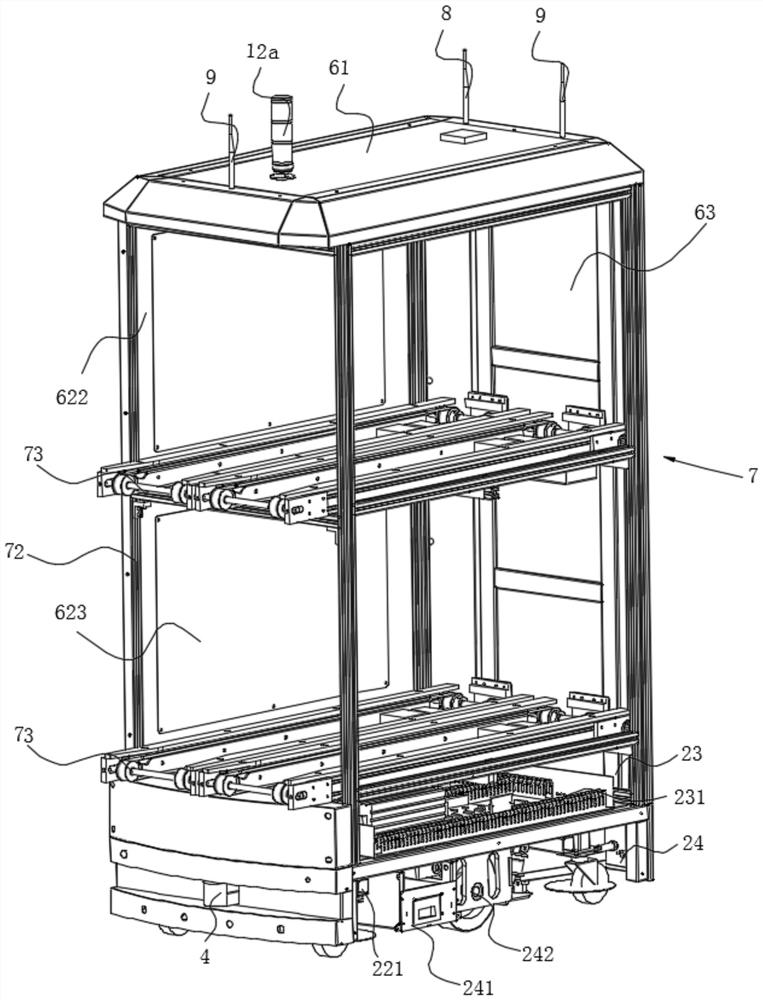

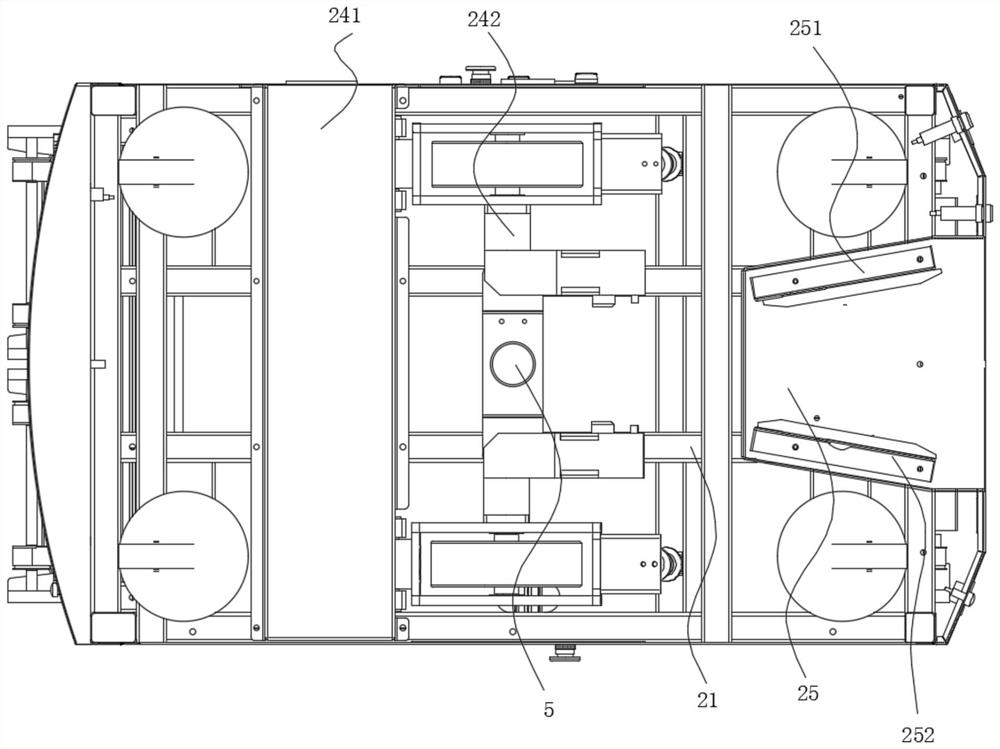

[0067] Such as Figure 1 ~ Figure 3 As shown, an AGV based on indoor microwave base station navigation includes a transport container 1 and an AGV vehicle body 2, and the AGV vehicle body 2 includes a vehicle body chassis 21 welded by rectangular tubes, a vehicle body shell 22 and a vehicle body frame .

[0068] Such as figure 1 and figure 2 As shown, the center of the front end of the AGV car body 2 is provided with a U-shaped groove inwardly, and the middle part of the U-shaped groove is provided with an obstacle detection sensor 4, which is used to detect and obtain information about obstacles around, and send this information Pass it to the control system to play the function of obstacle avoidance.

[0069] The conveying container 1 includes a container shell 6 and a conveying mechanism arranged in the container shell. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com