Novel wool conveying mechanism

A new type of plush technology, applied in the field of new plush transportation mechanism, can solve problems such as inconvenient transportation, reel collision, and quality impact of plush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

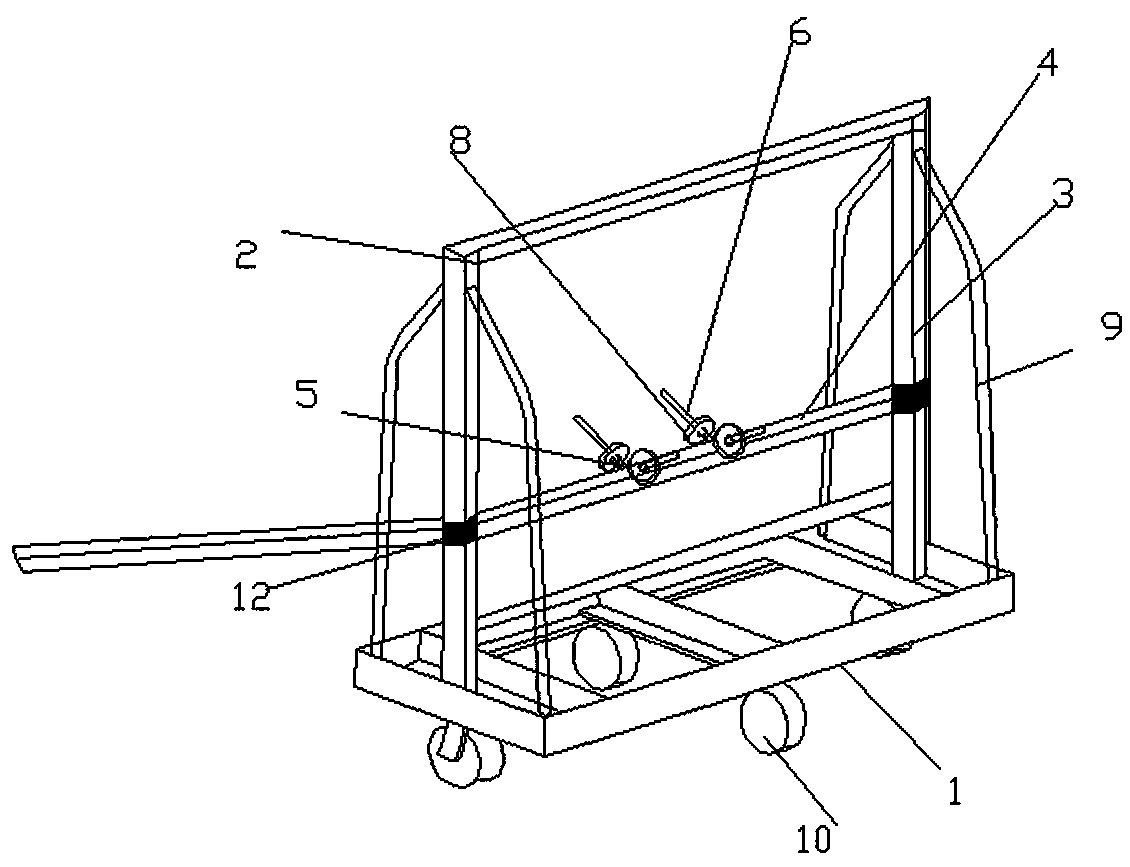

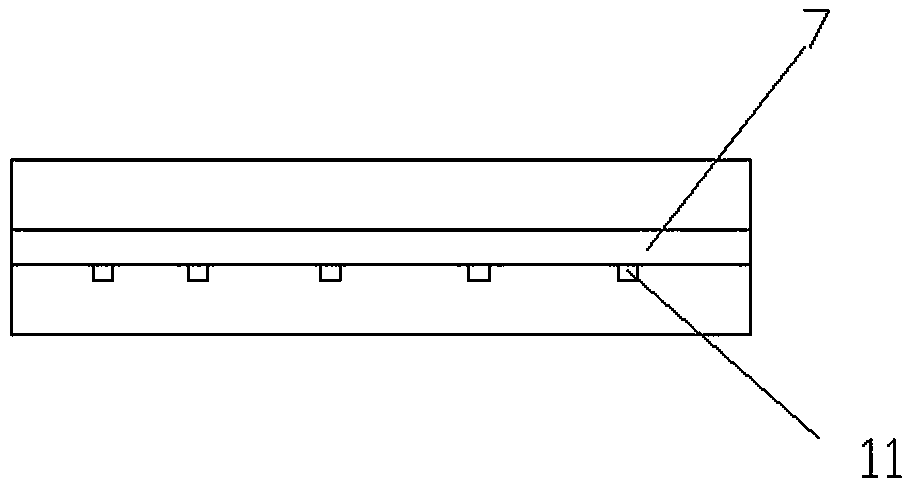

[0015] Such as Figure 1-3 As shown, in order to achieve the above purpose provided by this embodiment, the technical solution adopted by the present invention to solve the above technical problems is: a new type of plush transportation mechanism, which is characterized in that it includes a base 1, and the upper end of the base 1 is connected with a convenient wool The tube setting device 2 for placing the velvet roll, the tube setting device 2 includes longitudinal support beams 3 respectively arranged at both ends of the base 1, at least two layers of horizontal support rods 4 between the two longitudinal support beams 3, and the upper ends of the horizontal support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com