Novel wool transport vehicle

A technology of transport vehicles and plush, which is applied in the field of new plush transport vehicles, and can solve problems such as reel collision, impact on plush quality, and inconvenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

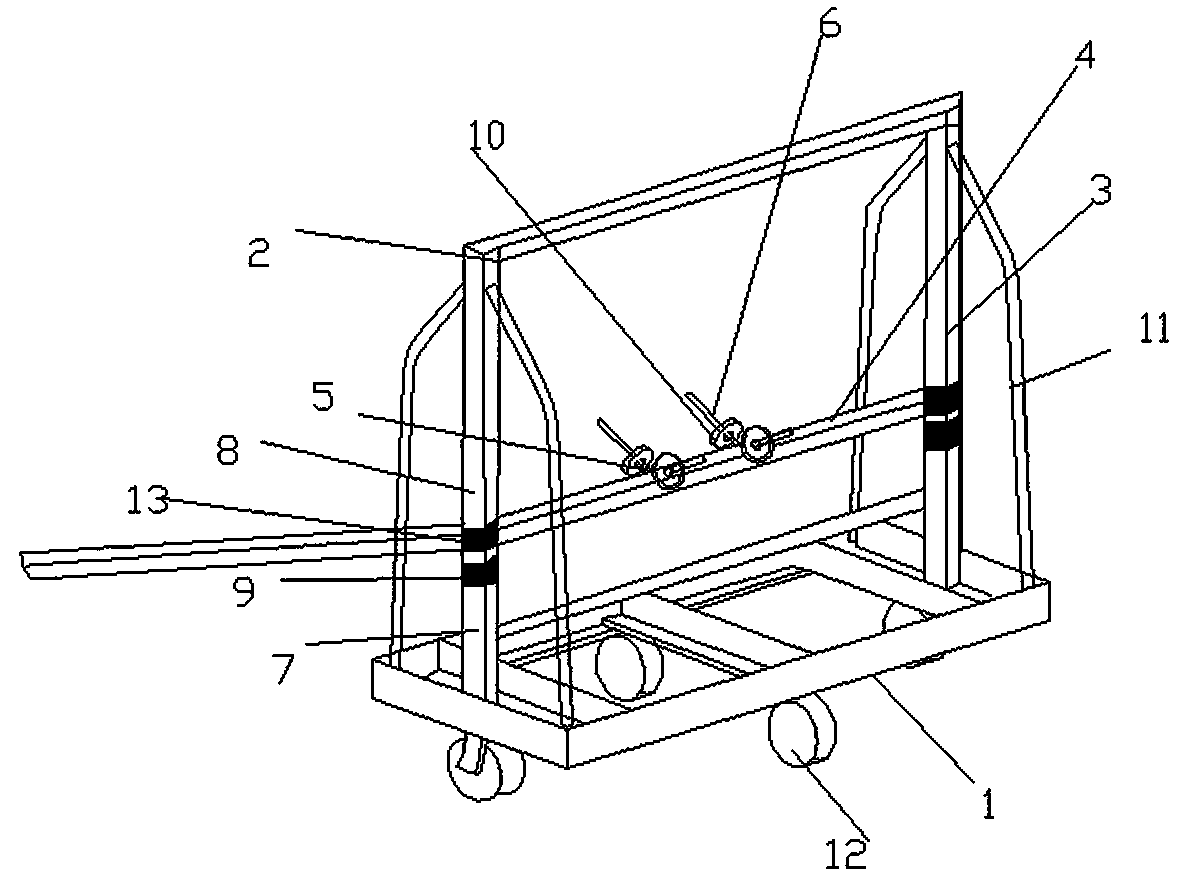

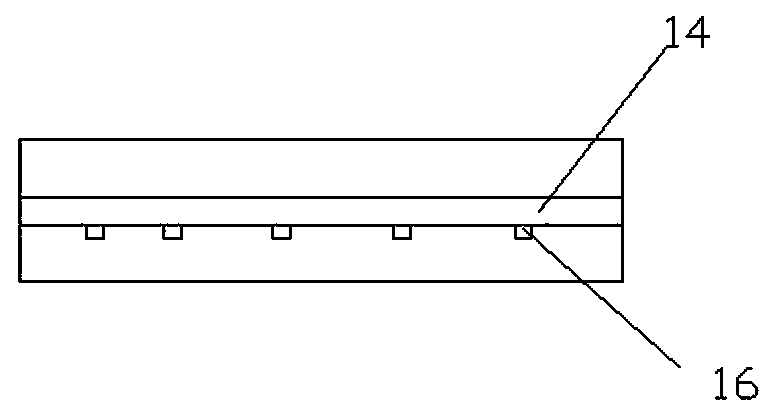

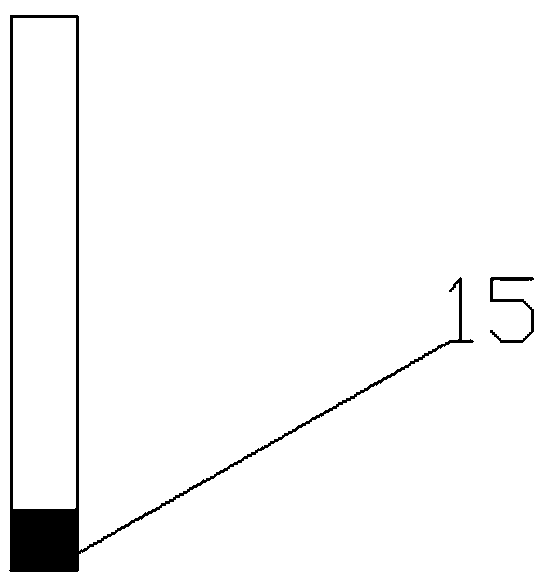

[0016] like Figure 1-3 As shown in the figure, a new type of plush transport vehicle provided by this embodiment includes a base 1, and the upper end of the base 1 is connected with a drum setting device 2 which is convenient for placing the plush reels. Longitudinal support beam 3, at least two layers of transverse support rods 4 between the two longitudinal support beams 3, the upper end of the transverse support rod 4 is connected with a number of cylinder placement groups 5, the cylinder placement group 5 includes two symmetrically arranged cylinder placement rods 6, the The longitudinal support beam 3 includes a first longitudinal support beam 7 and a second first longitudinal support be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com