How to weave knitwear

A technology for knitted fabrics and knitted fabrics, applied in the directions of knitting, weft knitting, textiles and papermaking, etc., can solve the problems of yarn breakage, increase the rotation amount of the integrated cylinder, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

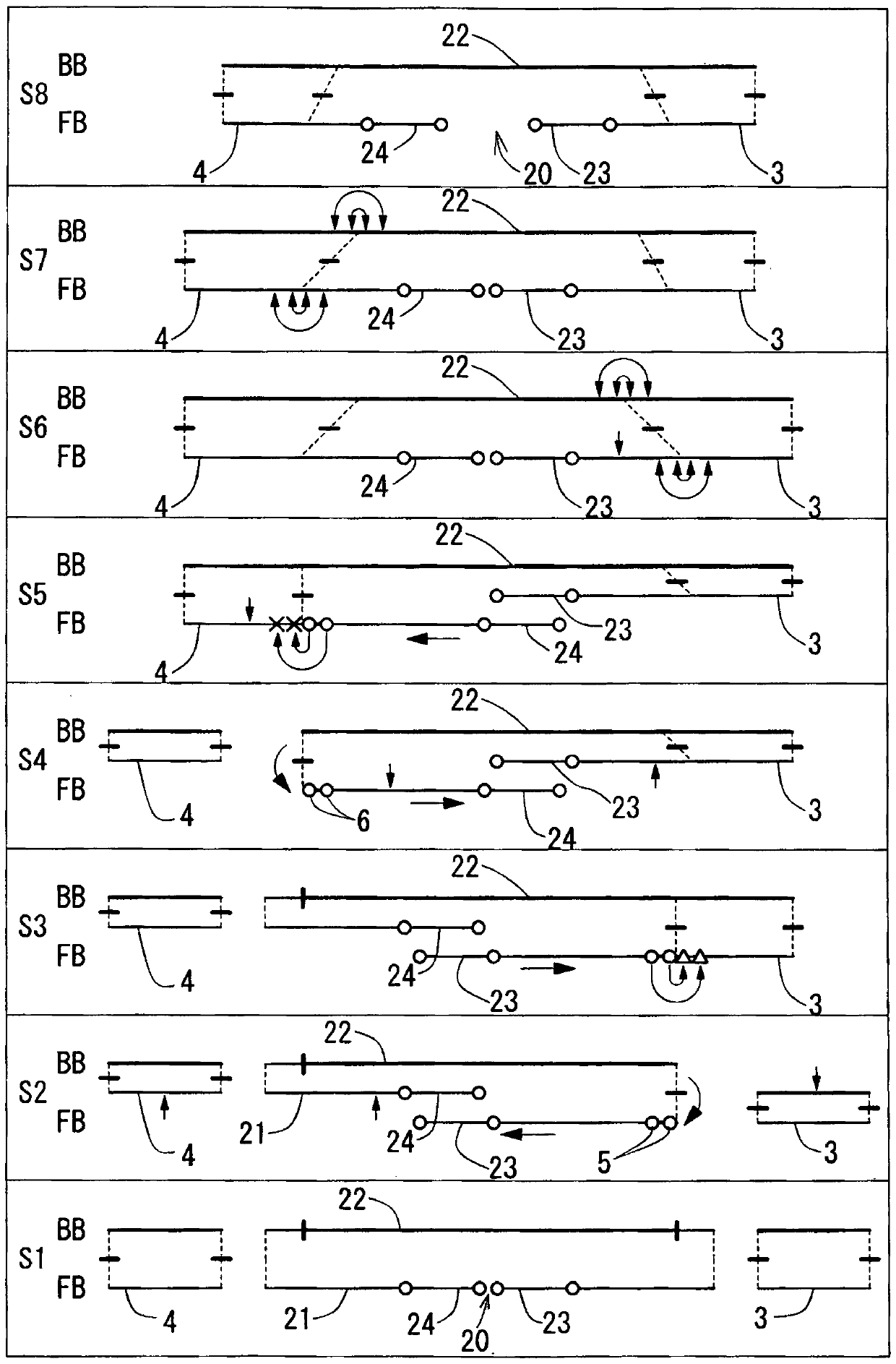

[0048] In Embodiment 1, an example of knitting a sweater (knitwear) using a flat knitting machine will be described. The flat knitting machine used in this example is a two-needle-bed flat knitting machine, but it may also be a four-needle-bed flat knitting machine. Moreover, the knitting needles provided by the flat knitting machine may be either latch needles or compound needles. As the compound needle, a compound needle having a holding function capable of temporarily holding the stitch at the tang formed at the front end of the slider is preferable.

[0049] "knitwear"

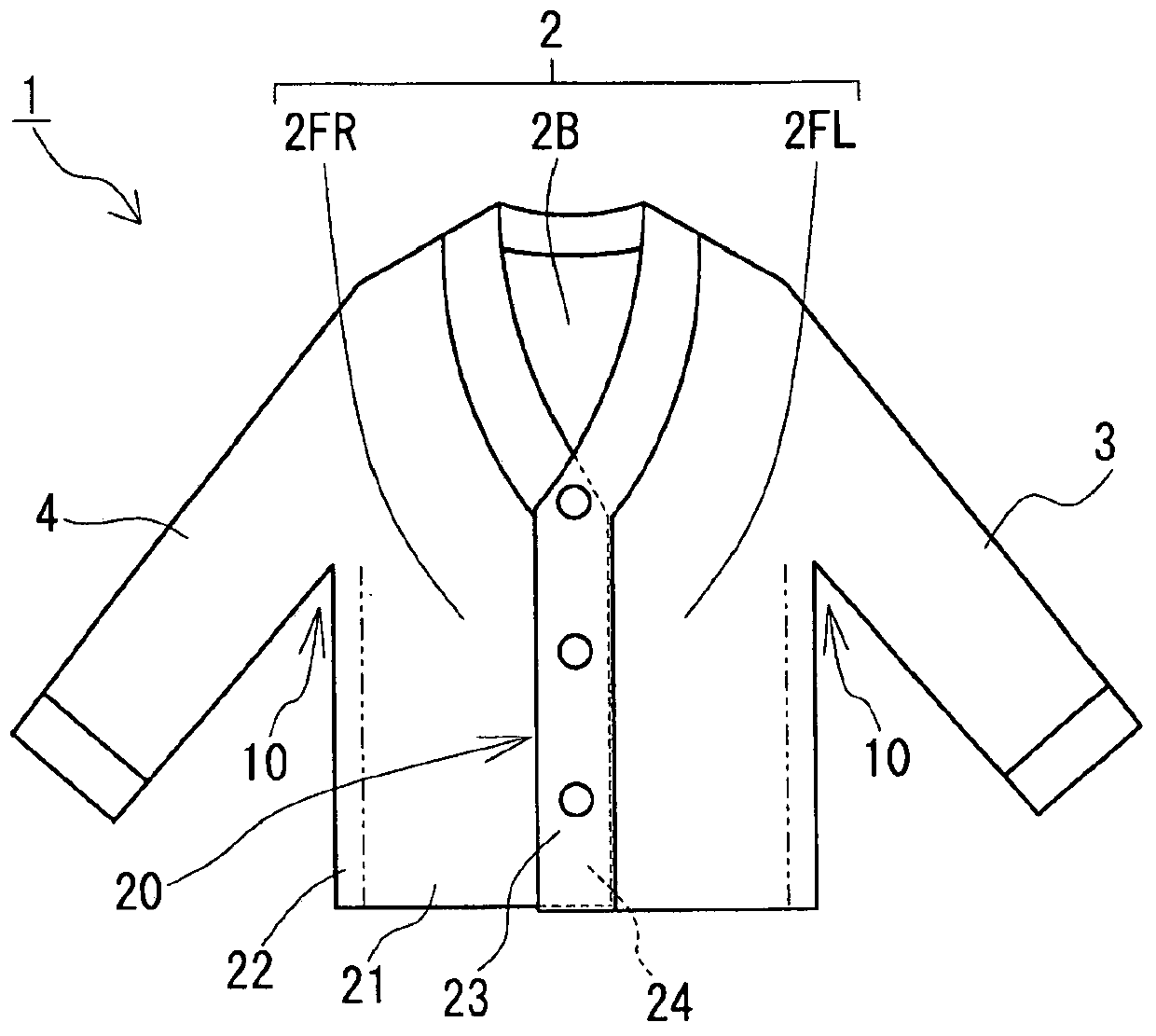

[0050] figure 1 The shown sweater (knitwear) 1 includes a body 2 , a left sleeve 3 and a right sleeve 4 connected to the body 2 . The body 2 of this example is composed of a back body 2B, a left front body 2FL, and a right front body 2FR. The left end (right end on paper) of the back body 2B is connected to the left end of the left front body 2FL, and the right end (left end on paper) of the back body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com