Wire rod for 460mpa level weather-resistant studs, production method and prepared studs

A 460mpa, wire rod technology, applied in the field of wire rods, can solve the problems of increased corrosion resistance gap, inability to transmit shear force, and damage to building structures, achieving significant weather resistance, reducing user processing, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

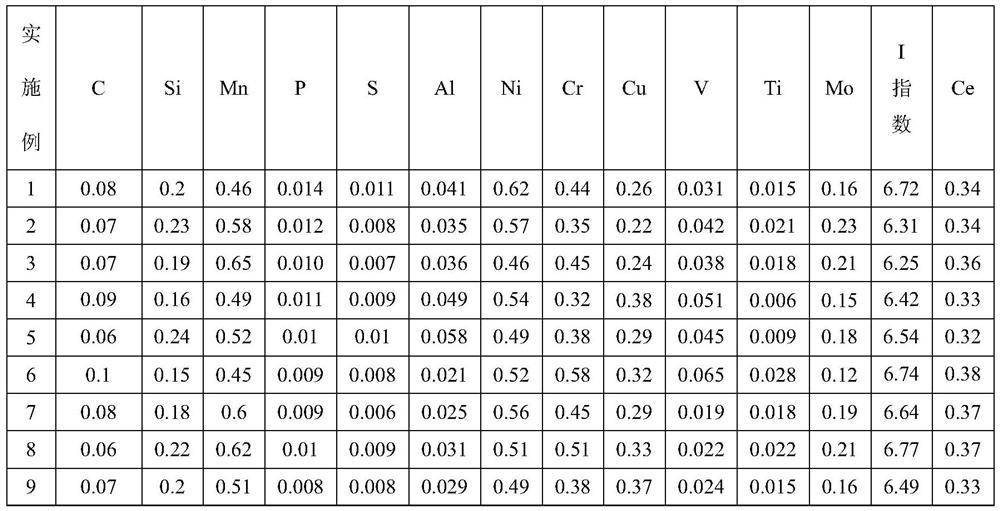

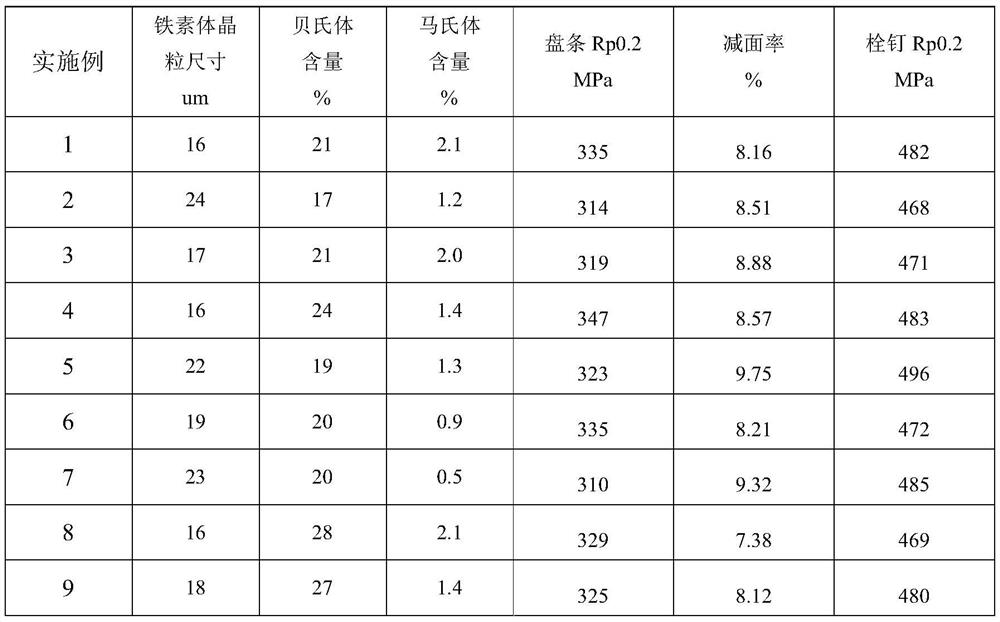

[0030]Below by embodiment the present invention will be further described.

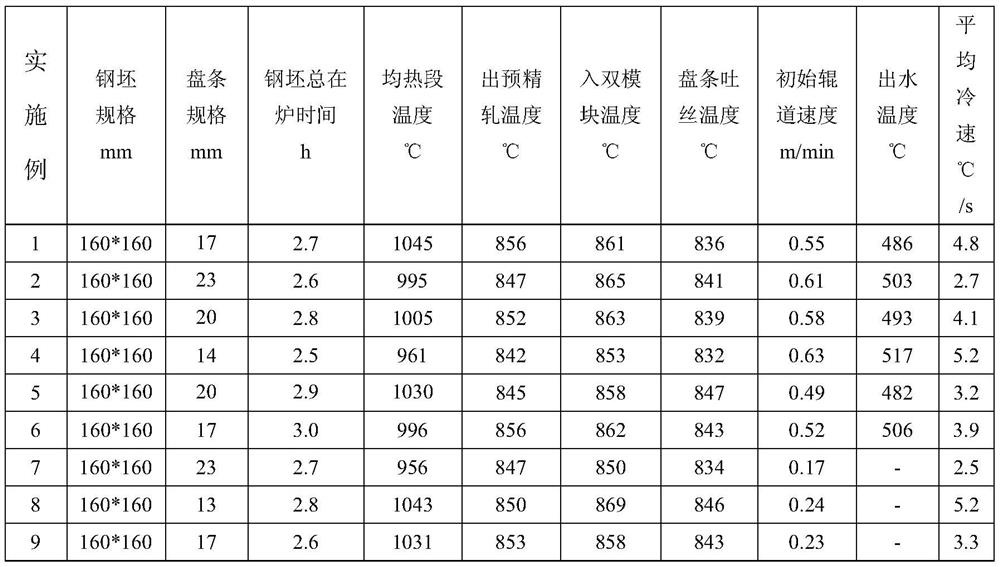

[0031] A production method for wire rods for 460MPa level weather-resistant studs, comprising smelting-continuous casting-slab heating-rolling-spinning-wire rod cooling,

[0032] (1) Steel billet heating: the steel billet cross-sectional dimension specification that produces wire rod adopts among the present invention is: (150mm~160mm) * (150mm~160mm), steel billet heating is always in furnace time 2.5~3 hours, soaking section temperature is at 950 ℃~1040℃;

[0033] (2) Rolling: the pre-finishing temperature of the rolled piece is controlled at 840 ° C ~ 860 ° C, and the temperature of the double module is 850 ° C ~ 870 ° C;

[0034] (3) Spinning: wire rod spinning diameter is 10.0mm~25.0mm, and wire spinning temperature is controlled at 830℃~850℃;

[0035] (4) Wire rod cooling: adopt air cooling or EDC cooling;

[0036] The air cooling: the initial roller table speed is 0.15-0.25m / min, and the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com