A method of manufacturing a solderable mixed metal package shell

A technology of encapsulating shells and mixed metals, applied in the manufacture of contact boxes/bases, etc., which can solve the problems of inability to meet the weldability requirements of flexible needle quick-plug housings, poor insulation and sealing performance between contacts and bases, and failure to support rapid Plug and unplug problems, to achieve the effect of simple structure, good air tightness, small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

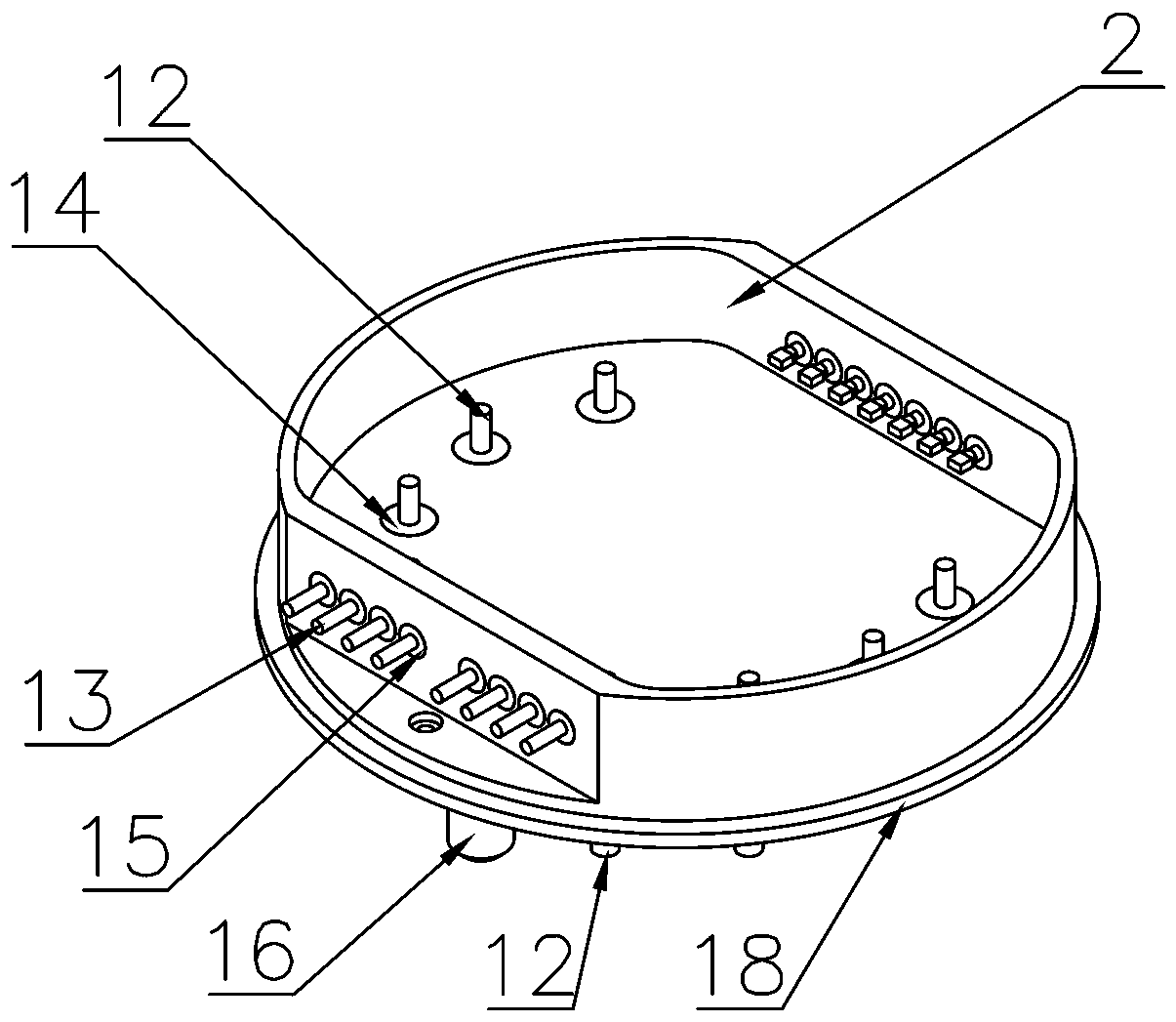

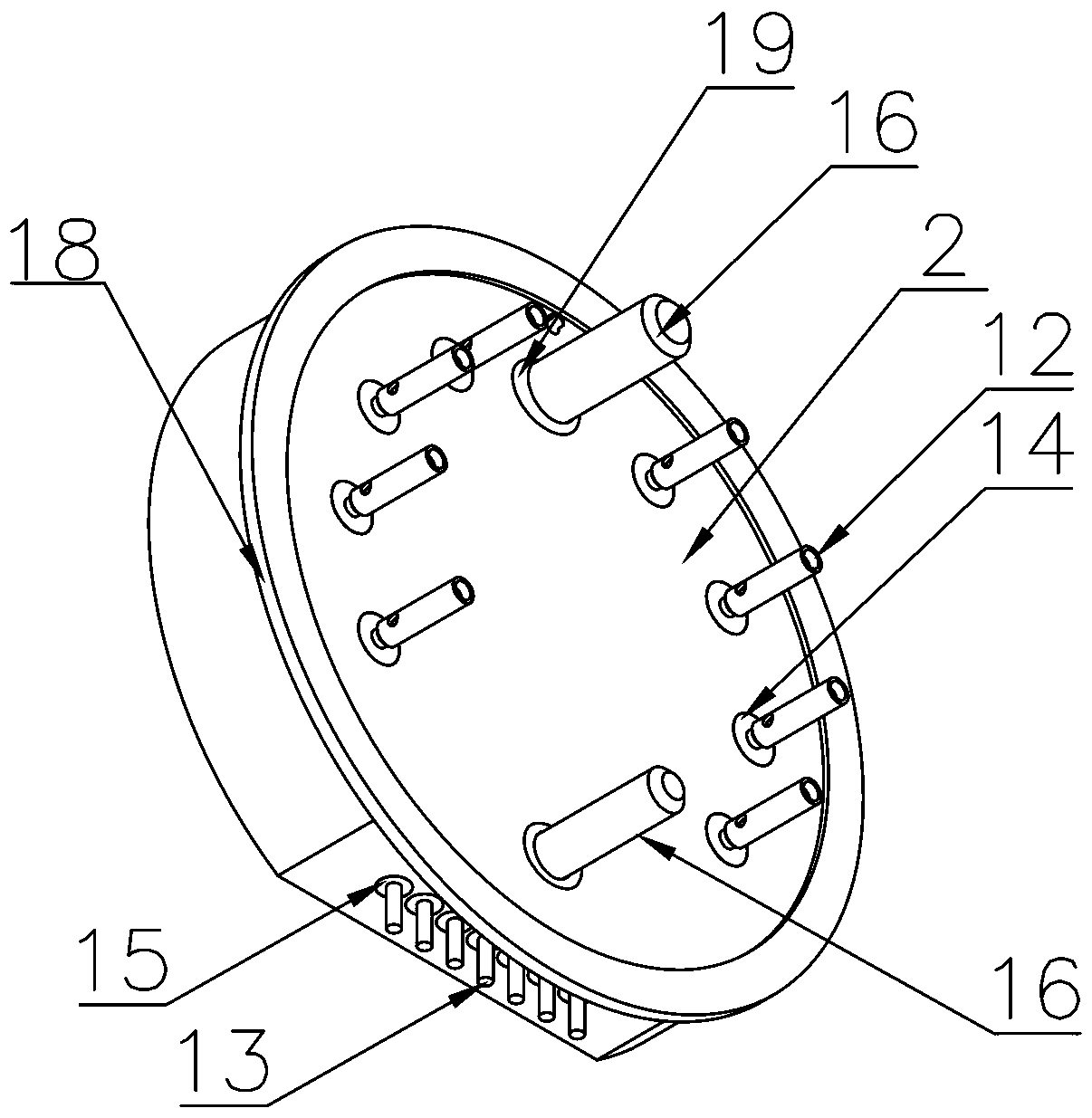

[0027] After described rigid socket 12, flattening lead wire 13 and guide post 16 are assembled with base 2, in the mold that graphite mold base 31 and outer locating mold 32 and inner locating mold 33 form, the operation steps of carrying out three times of sintering and fixing are as follows:

[0028] (1) One-time sintering

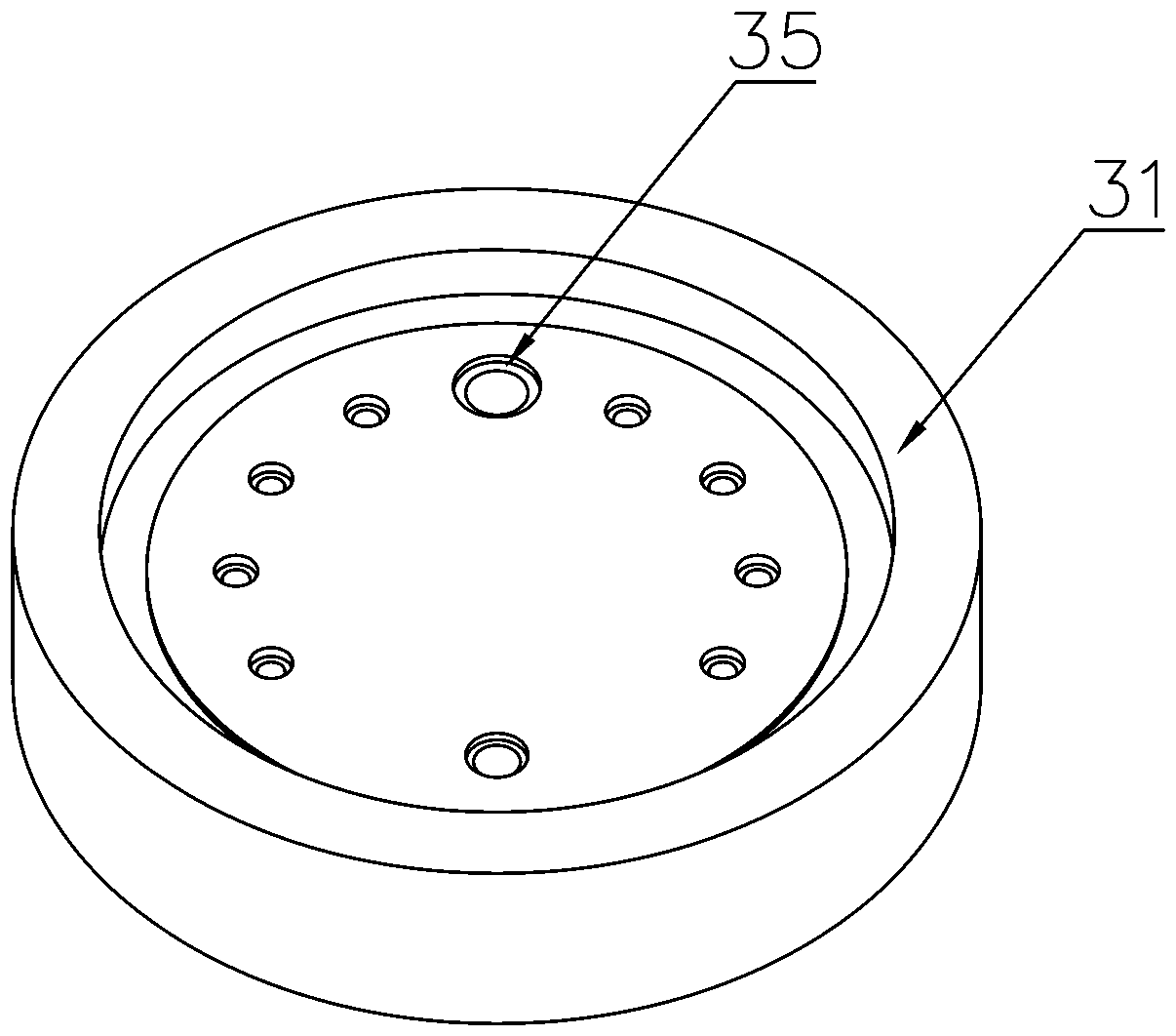

[0029] See attached Figure 6 , put the two guide posts 16 into the corresponding welding holes 19 on the base 2 according to the size of the diameter of the cylinder. The thickness of the two guide posts 16 is mainly to prevent the rigid jack 12 from being damaged by mis-insertion. Insert the graphite mold base 31, insert the guide column 16 into the corresponding positioning hole 35 on the graphite mold base 31, then insert the rigid jacks 12 into the corresponding positioning holes 35 of the graphite mold base 31 through the base 2, and put them on Hole glass insulator 14, ensure that jack glass insulator 14 is assembled in place, and subject to jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com