Cutter head floating structure

A floating structure and cutter head technology, applied in the field of razors, can solve the problem that the cutter head cannot be universally floated on the fuselage, so as to improve the shaving experience and ensure the effect of quick reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

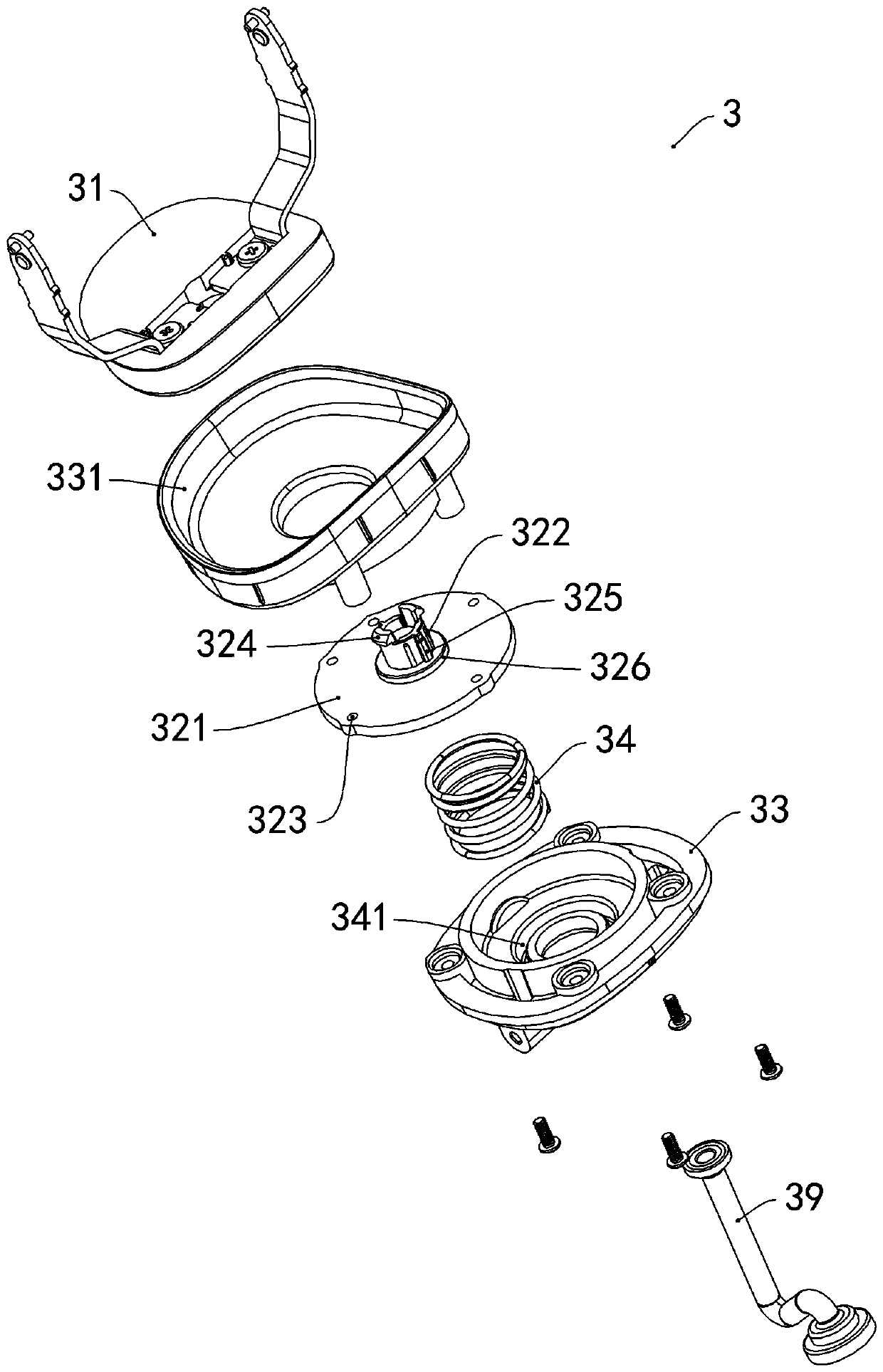

[0031] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings of the present invention.

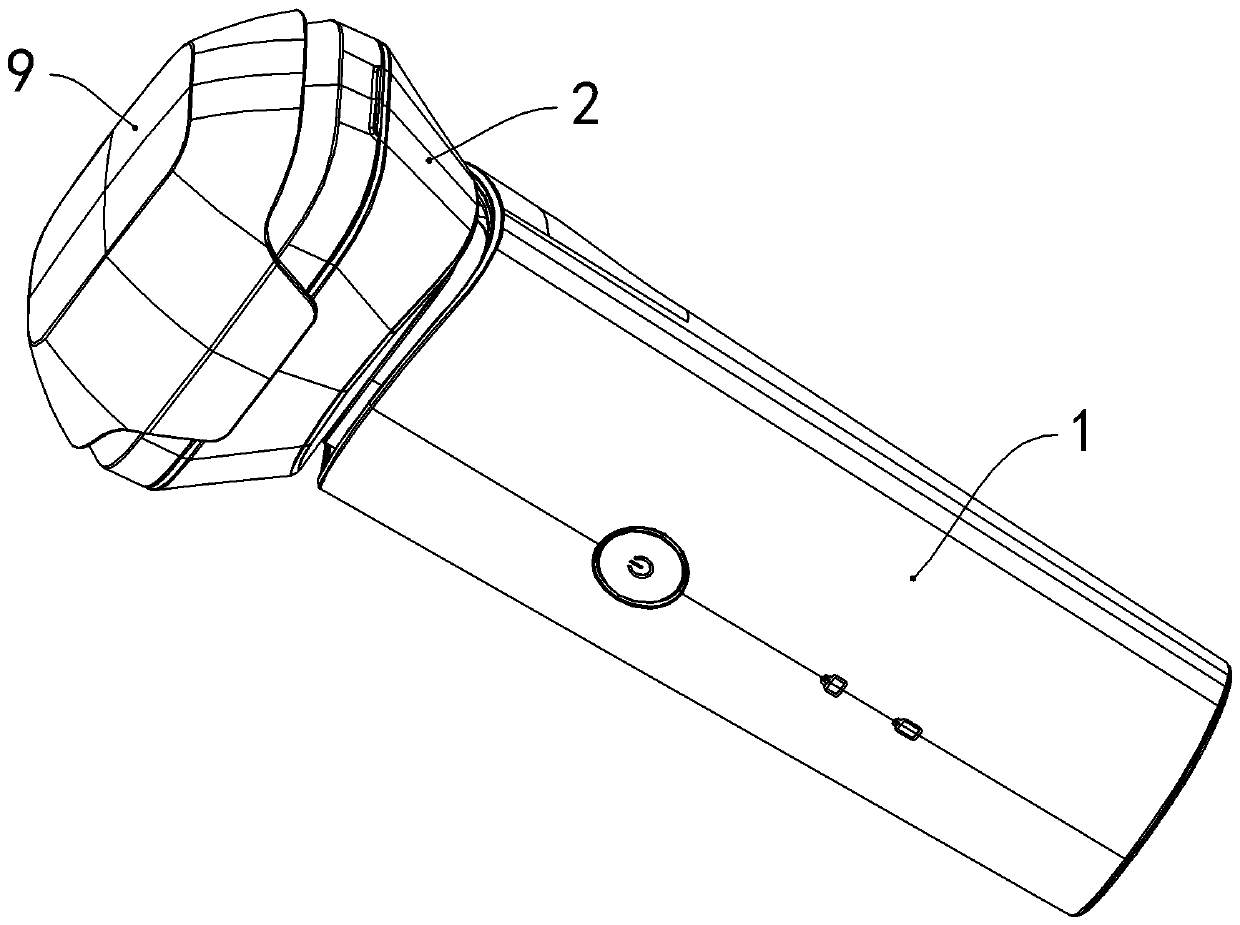

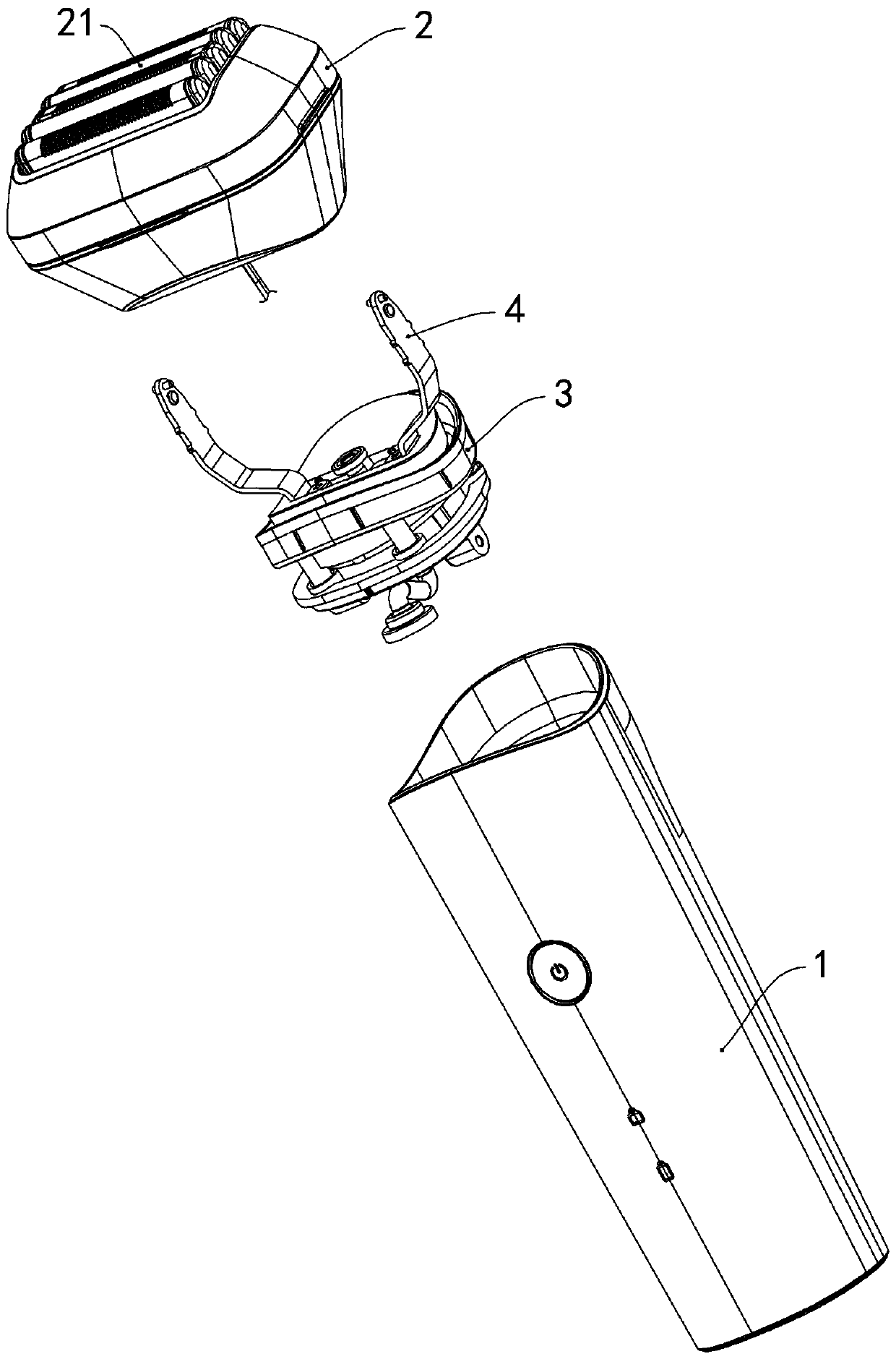

[0032] The cutter head floating structure of the present invention includes a body 1 and a cutter head 2 .

[0033] The body 1 is held by the user's hand when shaving. The body 1 is provided with a power source for driving the cutter head 2, such as a lithium battery, and the body 1 is also provided with components such as a PCB board and a switch for controlling the operation of the shaver.

[0034] Usually, the cutter head 2 is used to cut off the beard when shaving, and the cutter head 2 is provided with several knife net assemblies 21 . The knife net assembly 21 is usually provided with a knife net and an inner knife that can move relative to the knife net. Passing the beard through the knife net and the inner knife moving relative to the knife net can cut off the beard to realize the shaving function.

[0035] The cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com