Bottle feeding device and bottle feeding method

A bottle feeding and bottle feeding technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of crowded bottles, unsmooth pushing of bottles, broken bottles, etc., to prevent bottle pouring and broken bottles , The effect of improving the quality of the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

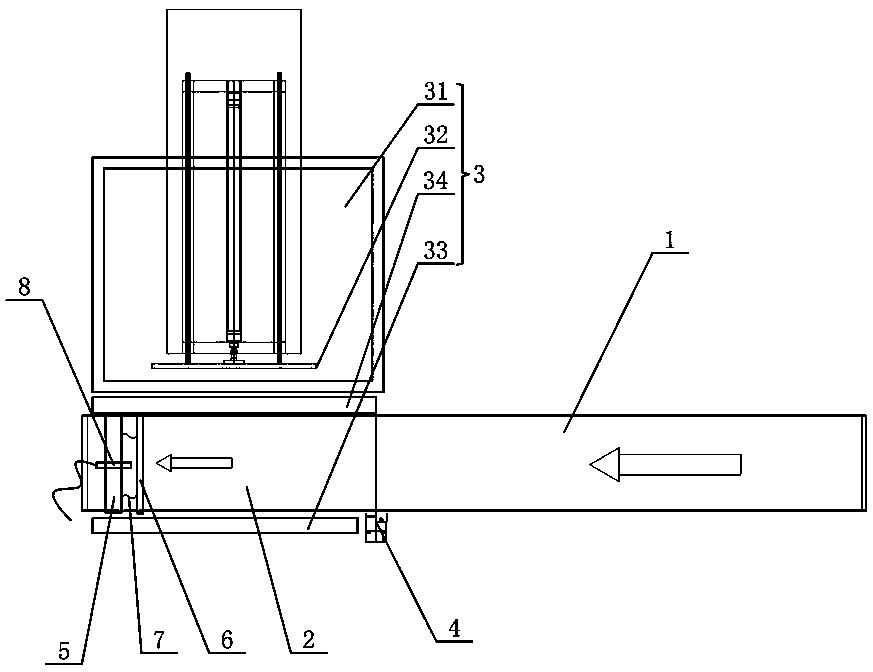

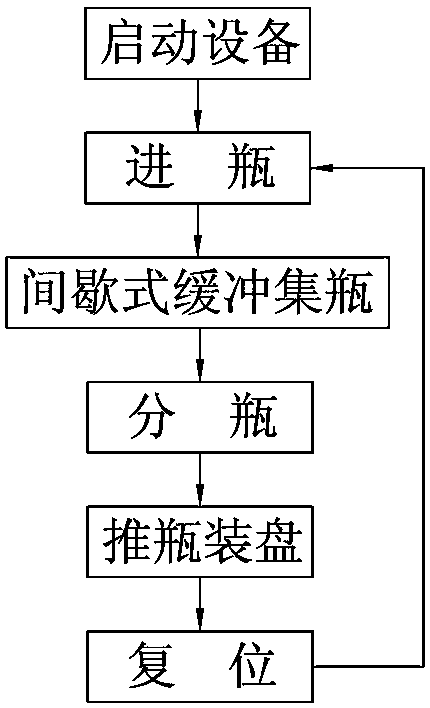

[0026] Such as figure 1 Shown, a kind of embodiment of bottle loading device of the present invention, comprises mutually butted front and back two-way bottle-feeding mesh belt 1 and bottle-feeding mesh belt 2, and bottle-going mesh belt 2 is set away from one end of positive and negative two-way bottle-feeding mesh belt 1 There is a plate loading mechanism 3, and a bottle separating mechanism 4 for bottle separation is provided on the side of the joint between the positive and negative two-way bottle feeding mesh belt 1 and the bottle feeding mesh belt 2, which is also installed on the bottle feeding mesh belt 2 and can be conveyed along the The servo baffle 5 and the telescopic baffle 6 that reciprocate in the same direction are connected by a spring 7, and the telescopic baffle 6 is close to the positive and negative two-way bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com