An AMT transmission off-line detection platform and its control method

A control method and transmission technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of lack of AMT transmission detection platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

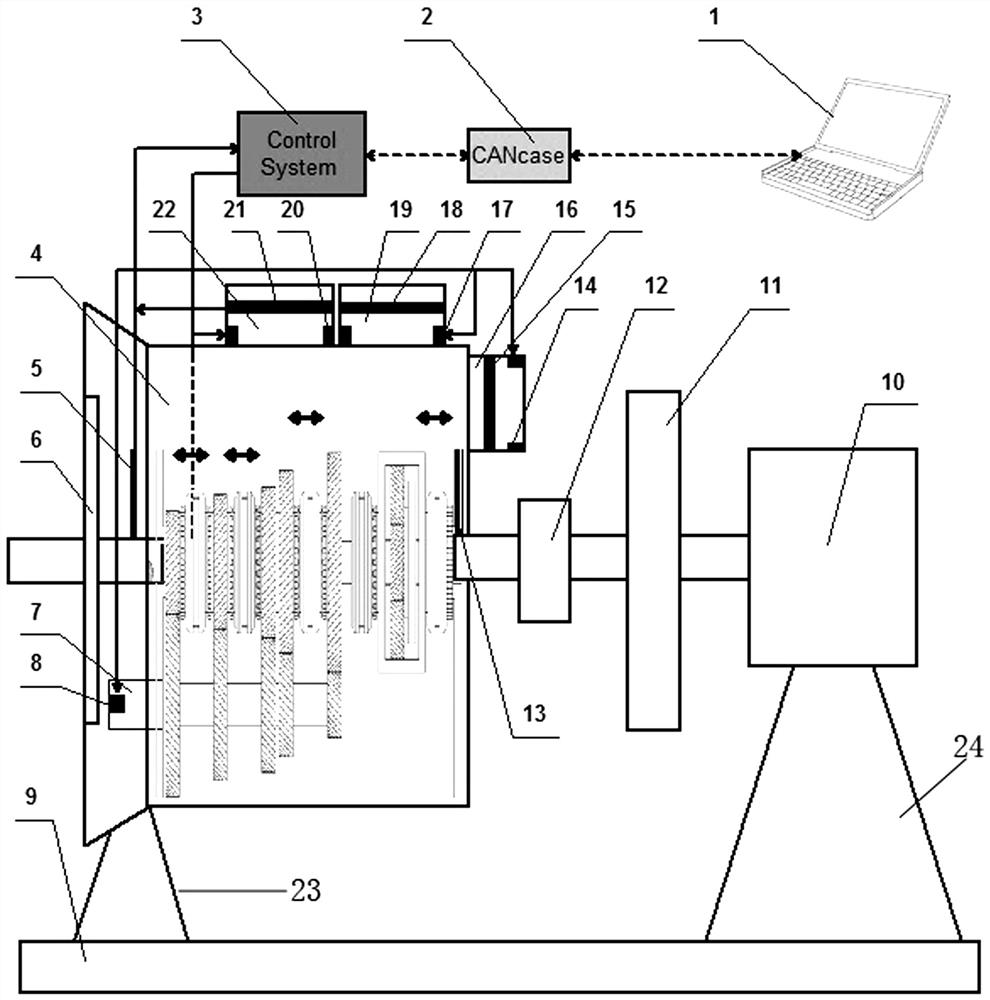

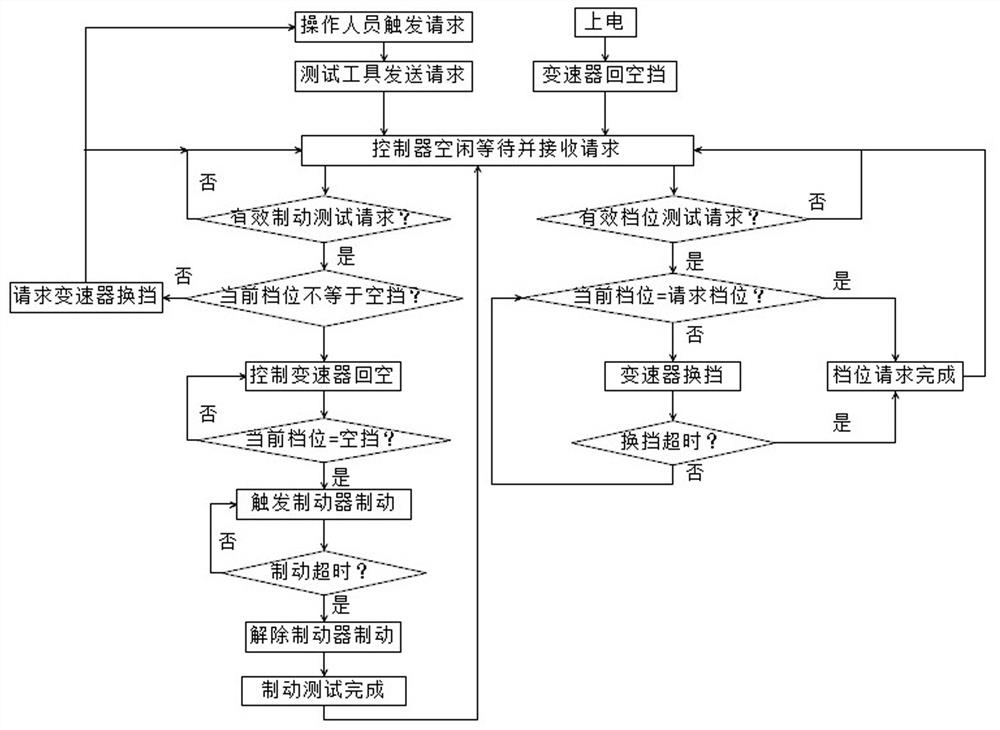

[0014]An AMT transmission lamination detection platform, including a computer, test tool, a control unit, a base 9, a drive motor 10 mounted on the base 9, and a transmission bracket 23 mounted on the base; the drive motor 10 output shaft connection is used for And the coupling 12 connected to the transmission output shaft is detected; the control unit 3 is connected to the test tool 2 through the wire harness, and the test tool 2 is connected to the computer 1 through the data line. The drive motor is independently controlled.

[0015]A counterweight 11 is also attached to the coupling 12 of the drive motor. A counterweight contributes to the connection between the drive motor and the transmission output shaft.

[0016]The computer 1 is a laptop; test tool 2 is a CANCase data tester; the control unit 3 microprocessor uses Freescale 32-bit microcontroller MPC5634; the drive motor is mounted on the motor holder 24 fixed to the base.

[0017]In order to clearly illustrate the technical charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com