Micro flying robot with connecting rod type foldable flapping wings

A flying robot and connecting rod technology, which is applied in the field of overall structure design of foldable flapping wing micro-aircraft, can solve the problems of assembly performance impact of the whole machine, wing bending and deformation, and inability to fold closer, so as to improve folding reliability, The effect of reducing flight load and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

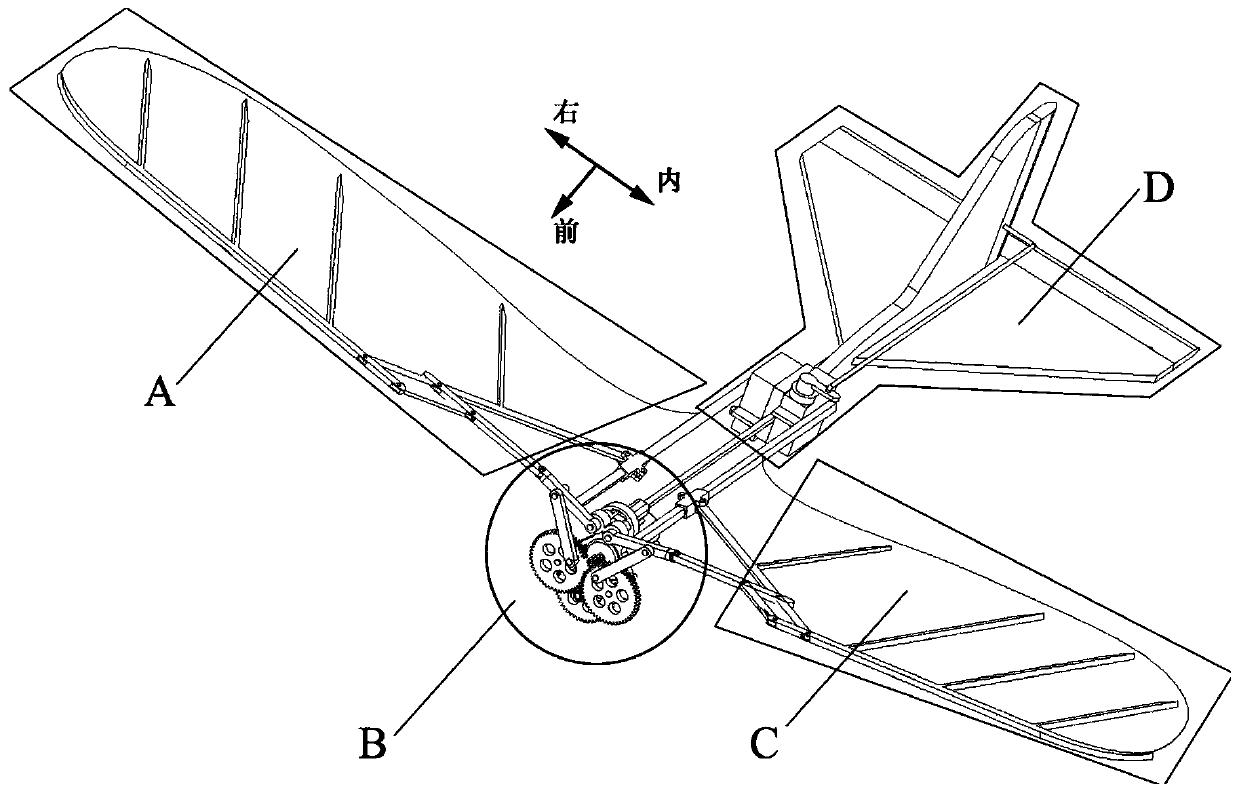

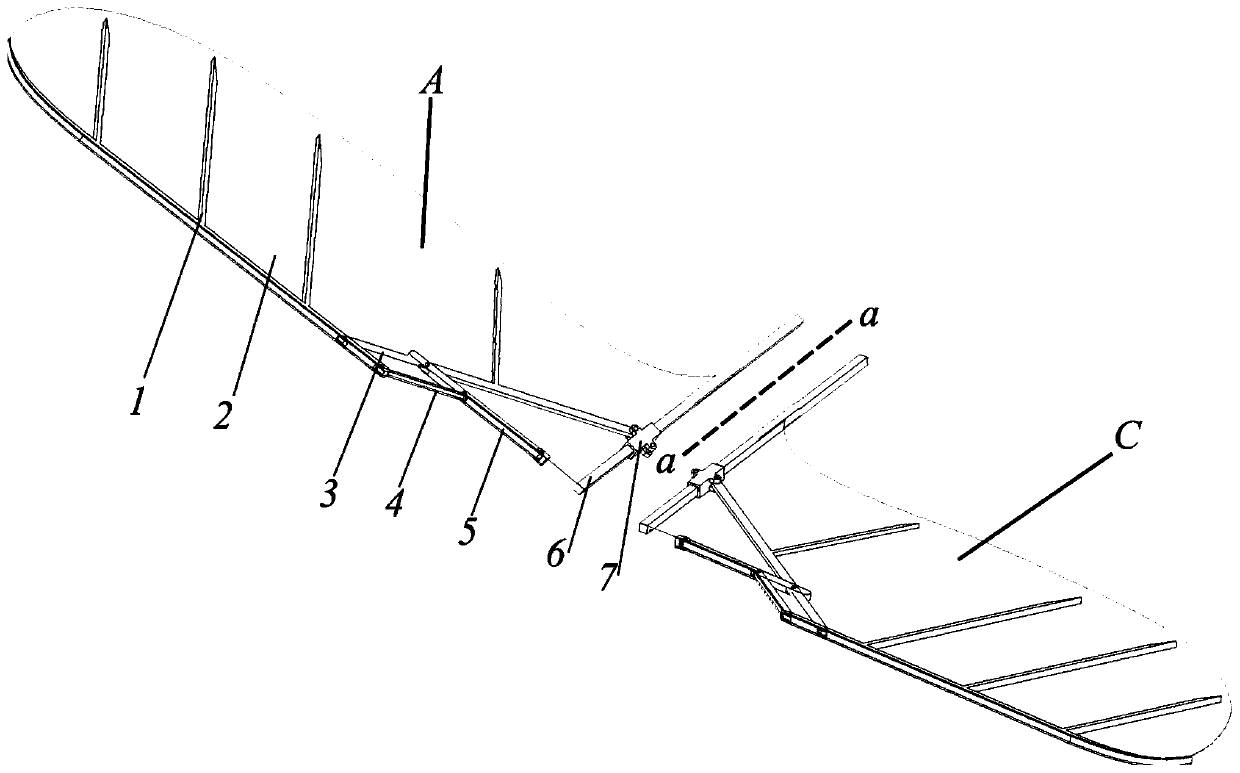

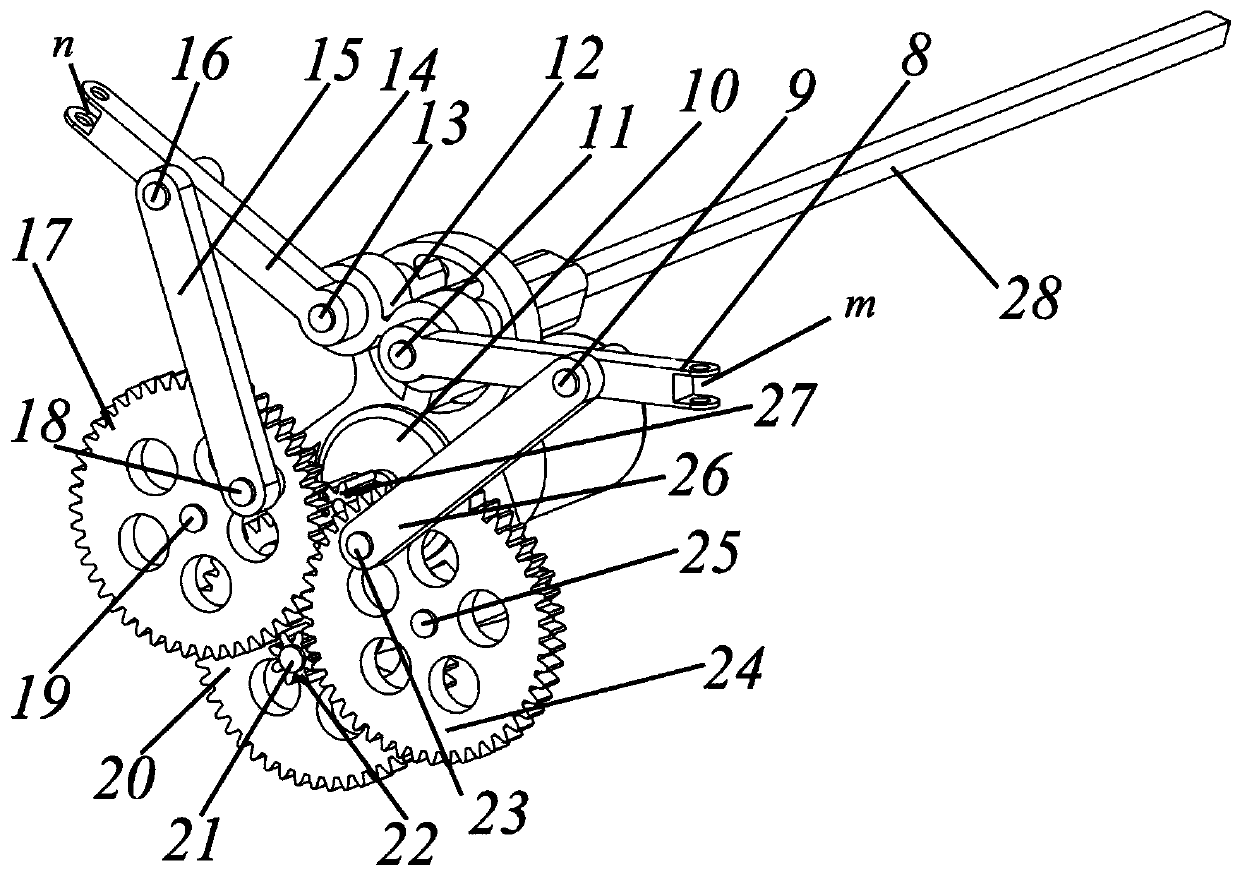

[0036] Such as figure 1 As shown, the connecting rod type foldable flapping wing miniature flying robot of the present invention is characterized in that: the present invention is made up of right wing A, nose device B, left wing C and empennage device D. Wherein: said right wing A and left wing C are symmetrical structures about the center line of the fuselage, the j hole of the swing link II5 in the right wing A passes through the bolt and the belt hole of the right swing link I14 in the nose device B The ear pair IIn is movably connected; the j hole of the swing rod II in the left wing C is movably connected with the holed ear pair Ip of the left swing rod I8 in the nose device B through bolts; the right slide rail 6 in the right wing A is connected with the empennage The side of the right steering gear 36 in the device D is affixed; the left slide rail in the left wing C is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com